Working on the firewall and mid fuse right now and this is about the time to install the bracket for the flap motor and fuel valve. When do I need to order the actual flap motor and fuel valve? Will it be 1000X easier if I get them now (assuming 0 lead time) or rivet the brackets in and move forward, coming to the fitment of the aftermarket stuff later on?

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When to order andair fuel valve and PH aviation flap motor kit?

- Thread starter RVFan671

- Start date

Working on the firewall and mid fuse right now and this is about the time to install the bracket for the flap motor and fuel valve. When do I need to order the actual flap motor and fuel valve? Will it be 1000X easier if I get them now (assuming 0 lead time) or rivet the brackets in and move forward, coming to the fitment of the aftermarket stuff later on?

As far as the flap actuator goes, it's not necessary to order it yet, but we do recommend that you make provisions for it. The stock flap bracket is located in the tunnel between the seat belt doublers. By far the easiest way to mount the PHA actuator is to move this bracket forward 1.5". This will require 1/8" shims to take up the space of the seatbelt doublers. If you have already built the tunnel, then you need to make up our piggyback brackets as shown in the installation manual. But it's much more elegant to just move the existing bracket forward if you still have access.

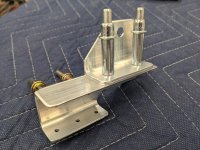

Here is a picture:

Last edited:

Fenderbean

Well Known Member

I hope its okay if I ask here but besides a personal preference is there anything I should consider when decided to go this route vs the stock? Thanks

I believe the PH Aviation flap motor is almost the same price as Van's motor plus indicator (might even be cheaper than vans) and supposedly way easier install than the effort for the Van's indicator since its built into the motor on PH aviation.

Fuel valve I'm not sure but I dont think Van's supports a return line which is required for EFI. I'm probably not going with EFI but would like to plumb a return line setup so the upgrade is easier in the future.

Fuel valve I'm not sure but I dont think Van's supports a return line which is required for EFI. I'm probably not going with EFI but would like to plumb a return line setup so the upgrade is easier in the future.

Andair lead time

I ordered my fuel valve directly from Andair about 6 weeks ago to get the exact configuration I wanted. They said at that time the lead time was 6-8 weeks. I would expect with the UK lockdown that these numbers will grow and I honestly don't expect mine till mid January at this point.

I ordered my fuel valve directly from Andair about 6 weeks ago to get the exact configuration I wanted. They said at that time the lead time was 6-8 weeks. I would expect with the UK lockdown that these numbers will grow and I honestly don't expect mine till mid January at this point.

Lionclaw

Well Known Member

I ordered my fuel valve directly from Andair about 6 weeks ago to get the exact configuration I wanted. They said at that time the lead time was 6-8 weeks. I would expect with the UK lockdown that these numbers will grow and I honestly don't expect mine till mid January at this point.

As a data point, my order confirmation from Andair was received on 7 September and the valve showed up at my door today. 14 weeks.

As a data point, my order confirmation from Andair was received on 7 September and the valve showed up at my door today. 14 weeks.

I am discovering many delivery times are plus or minus. The plus is plus 200% and the minus is minus 2% these days. I have a white board in the shop that I am writing down dates I have ordered stuff and the proposed delivery. Managing delivery dates is almost becoming loggable hours on the project.

Fenderbean

Well Known Member

I believe the PH Aviation flap motor is almost the same price as Van's motor plus indicator (might even be cheaper than vans) and supposedly way easier install than the effort for the Van's indicator since its built into the motor on PH aviation.

Fuel valve I'm not sure but I dont think Van's supports a return line which is required for EFI. I'm probably not going with EFI but would like to plumb a return line setup so the upgrade is easier in the future.

Thanks I had already decided on the valve but your comment makes sense and I like the idea of easier. I feel like there are a lot of things that could be updated on vans side but since I can exclude items form my purchase i see no reason to get an updated part. If I had to buy all the items it would probably be a different story

I am trying to fabricate a bracket for the PH flap actuator and am going to be moving the stock flap bracket forward 1.5" and adding 1/8" shims to make up the space of the seat belt doublers. That being said the PH actuator doesn't seem to fit between the stock flap angle brackets and looks like I need create about 3/8" more space between the brackets.

-Anyone have pictures of how the accomplished that?

-Also does the flap motor need vertical play? It appears to be hitting the stock flap bracket so should I fabricate the new angle brackets to have the mounting bolt hole higher?

-Anyone have pictures of how the accomplished that?

-Also does the flap motor need vertical play? It appears to be hitting the stock flap bracket so should I fabricate the new angle brackets to have the mounting bolt hole higher?

Weefle

Well Known Member

I believe the PH Aviation flap motor is almost the same price as Van's motor plus indicator (might even be cheaper than vans) and supposedly way easier install than the effort for the Van's indicator since its built into the motor on PH aviation.

Fuel valve I'm not sure but I dont think Van's supports a return line which is required for EFI. I'm probably not going with EFI but would like to plumb a return line setup so the upgrade is easier in the future.

Vans flap motor is 498.00 as for the Andair, order it early as I ordered mine about 4 months ago and it finally shippied last week. Covid has messed a lot of the supply chain.

I am trying to fabricate a bracket for the PH flap actuator and am going to be moving the stock flap bracket forward 1.5" and adding 1/8" shims to make up the space of the seat belt doublers. That being said the PH actuator doesn't seem to fit between the stock flap angle brackets and looks like I need create about 3/8" more space between the brackets.

-Anyone have pictures of how the accomplished that?

-Also does the flap motor need vertical play? It appears to be hitting the stock flap bracket so should I fabricate the new angle brackets to have the mounting bolt hole higher?

I installed it, not flying yet. The flap actuator should fit between the stock flap bracket install positions, but you do need to refab the brackets per the instructions. Here's what I did: https://www.wheelswelded.com/fuse/mod/Flap-Motor-Install/

As far as the flap actuator goes, it's not necessary to order it yet, but we do recommend that you make provisions for it. The stock flap bracket is located in the tunnel between the seat belt doublers. By far the easiest way to mount the PHA actuator is to move this bracket forward 1.5". This will require 1/8" shims to take up the space of the seatbelt doublers. If you have already built the tunnel, then you need to make up our piggyback brackets as shown in the installation manual. But it's much more elegant to just move the existing bracket forward if you still have access.

Here is a picture:

View attachment 5431

Pat,

I like the idea of moving the main bracket forward but the picture you posted doesn't align with the sizes of the actual parts that I have in hand. The spacing between the standard brackets is approximately 1 3/8". The width of the flap actuator casing is approximately 1 13/16". What am I missing?

Attachments

Pat,

I like the idea of moving the main bracket forward but the picture you posted doesn't align with the sizes of the actual parts that I have in hand. The spacing between the standard brackets is approximately 1 3/8". The width of the flap actuator casing is approximately 1 13/16". What am I missing?

Thanks, this is my question exactly. I have moved everything back 1.5" and made 1/8" spacers as described. Also, it appears the bolt on the Vans brackets that the flap bolt goes through is slightly too low and makes the flap actuator point more vertical. I am not sure how that will affect the final attach as I am not to that point yet. I might remake the Vans brackets with thicker stock and cut away the portion of the bracket hits the flap actuator and move the bolt holes up 1/4" or so. I will try that when I get to the final flap install.

Dad's RV-10

Well Known Member

I'm curious as well.What does the PH flap actuator do that running the stock one through a vertical power block not do? It’s my understanding that it can handle position monitoring, one touch flap actuation, etc.

UnPossible

Well Known Member

The flap actuator from Vans doesn't have any mechanism to detect flap position. In order to view the position on the VP-X, you will need to add an potentiometer. I think I used a Ray Allen POS-12 on my 7A. The PH Aviation flap motor has the position sensor built into the actuator.

http://www.rayallencompany.com/products/indsens.html

http://www.rayallencompany.com/products/indsens.html

The flap actuator from Vans doesn't have any mechanism to detect flap position. In order to view the position on the VP-X, you will need to add an potentiometer. I think I used a Ray Allen POS-12 on my 7A. The PH Aviation flap motor has the position sensor built into the actuator.

http://www.rayallencompany.com/products/indsens.html

This was my understanding as well which is why I went with PH actuator. Plus price was essentially a wash. The PH actuator feels robust and well made.

PH Aviation Flap Actuator Brackets

To loop back on my previous post in this thread, I ended up making the brackets that PH Aviation describes in their plans. It was easier to make the brackets now than it would have been with the bottom skins riveted into place.

I did run into a gotcha with the vertical spacing at full extension so I had to add some spacers.

Full details on my build log for anyone that finds it useful (https://airplane.allanglen.com/2021/06/19/flap-actuator-brackets/). I also included a video clip showing the speed and range of travel.

To loop back on my previous post in this thread, I ended up making the brackets that PH Aviation describes in their plans. It was easier to make the brackets now than it would have been with the bottom skins riveted into place.

I did run into a gotcha with the vertical spacing at full extension so I had to add some spacers.

Full details on my build log for anyone that finds it useful (https://airplane.allanglen.com/2021/06/19/flap-actuator-brackets/). I also included a video clip showing the speed and range of travel.

Attachments

As a data point, my order confirmation from Andair was received on 7 September and the valve showed up at my door today. 14 weeks.

I’m at 15 weeks now.