aviationgeek84

Well Known Member

Hi All,

I am getting ready to trim my HS-710 and HS-714 pieces for my front spar on the horizontal stabilizer. Is there a "better" way to go about doing this to get consistent results on both other than the info Van's provides in the instructions and plans?

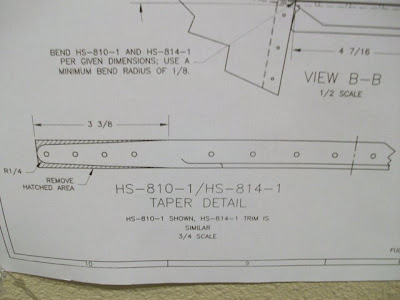

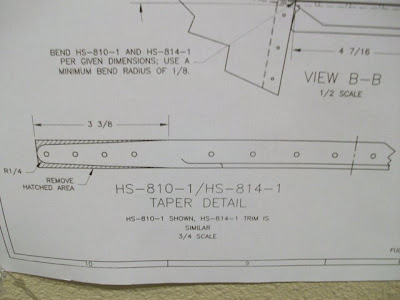

I did measure out the 3 3/8" called out in the plans (see photos) and note that 1/4" radius marked on the plans as well. I've attached the photos of what I'm looking at. Just looking for tips/tricks.

Thanks!

I am getting ready to trim my HS-710 and HS-714 pieces for my front spar on the horizontal stabilizer. Is there a "better" way to go about doing this to get consistent results on both other than the info Van's provides in the instructions and plans?

I did measure out the 3 3/8" called out in the plans (see photos) and note that 1/4" radius marked on the plans as well. I've attached the photos of what I'm looking at. Just looking for tips/tricks.

Thanks!