RVG8tor

Well Known Member

On the -8 the vent is just the 1/4" tube cut off at an angle. I bought a bulk head fitting that is cut to be a vent but this does not work on the -8 due to the double floor, there is no way to tighten up the nut. I was making a screen to go over the opening of the tube and I wondered if this was more harm than good. If there was no screen a bug could clog the hole, but it also could just go all the way to the tank and not clog the vent. I am thinking the screen will act like a collector, now smaller bugs will stick between the screen openings, after going through a few bugs you would get an obstruction. Now if icing were encountered to me the screen would collect even more ice than if there were no screen.

Anyone flying with a screen on the fuel vent on the -8 have any issues with bug guts collecting on the screen? I you don't have a screen do you get debris in your tanks?

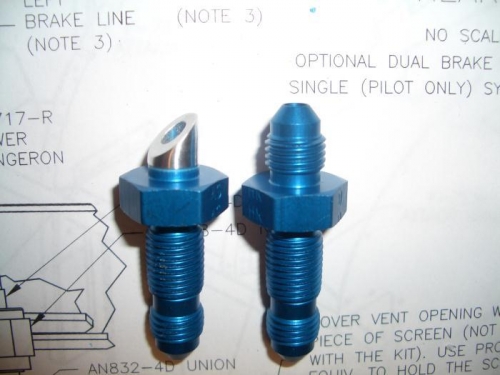

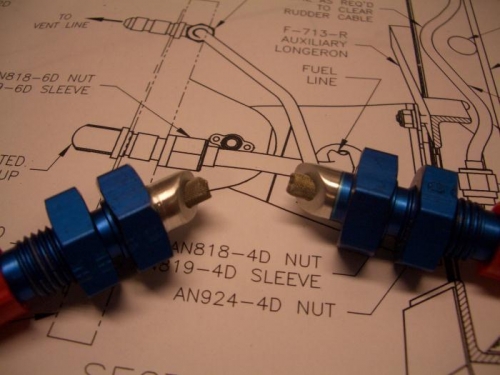

Pictured are my screen in the works (I will smooth the JB weld once set up) on the vent tube and a shot of the AN fitting I bought that I can't use, or at least I can't find a way to make it work on the eight. I am using a garden hose screen that is stainless steel; it has a more open mesh than some of the brass screens I have seen.

This is my screen in the works, I am using JB weld for this prototype.

This is the AN fitting vent, the screen is very fine mesh not in the direct wind stream.

Cheers

Anyone flying with a screen on the fuel vent on the -8 have any issues with bug guts collecting on the screen? I you don't have a screen do you get debris in your tanks?

Pictured are my screen in the works (I will smooth the JB weld once set up) on the vent tube and a shot of the AN fitting I bought that I can't use, or at least I can't find a way to make it work on the eight. I am using a garden hose screen that is stainless steel; it has a more open mesh than some of the brass screens I have seen.

This is my screen in the works, I am using JB weld for this prototype.

This is the AN fitting vent, the screen is very fine mesh not in the direct wind stream.

Cheers