Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oversquared Lycoming chart for -390?

- Thread starter Av8rRob

- Start date

Here is some interesting reading.

https://resources.savvyaviation.com...30 1300 F7 Benefits of Running Oversquare.pdf

https://resources.savvyaviation.com...30 1300 F7 Benefits of Running Oversquare.pdf

Av8rRob

Well Known Member

Here is some interesting reading.

https://resources.savvyaviation.com...30 1300 F7 Benefits of Running Oversquare.pdf

Exactly, he shows the chart for the -360 so where is the -390 chart?

Untainted123

Well Known Member

Use the app

Using the free app is way easier, correlates directly to the book, handles all the calculations and chart tracing for you.

AircraftPower by James Petty

https://apps.apple.com/us/app/aircraftpower/id718023187

iOS only, but that’s probably not a limitation for most.

Basically, you can choose any MAP/RPM combo you want (that your prop restrictions will allow) that gets you the percent power you want.

Combined with the Savvy info above (assuming no prop restriction), let’s say 22/2400 gave you 75% power at whatever altitude. Using the chart/app, you see that 25/2000 also gives you 75% power. You should choose the over square, low rpm setting vs the under square, high rpm, for the host of reasons in the Savvy presentation.

Using the free app is way easier, correlates directly to the book, handles all the calculations and chart tracing for you.

AircraftPower by James Petty

https://apps.apple.com/us/app/aircraftpower/id718023187

iOS only, but that’s probably not a limitation for most.

Basically, you can choose any MAP/RPM combo you want (that your prop restrictions will allow) that gets you the percent power you want.

Combined with the Savvy info above (assuming no prop restriction), let’s say 22/2400 gave you 75% power at whatever altitude. Using the chart/app, you see that 25/2000 also gives you 75% power. You should choose the over square, low rpm setting vs the under square, high rpm, for the host of reasons in the Savvy presentation.

Av8rRob

Well Known Member

Using the free app is way easier, correlates directly to the book, handles all the calculations and chart tracing for you.

AircraftPower by James Petty

https://apps.apple.com/us/app/aircraftpower/id718023187

iOS only, but that’s probably not a limitation for most.

Basically, you can choose any MAP/RPM combo you want (that your prop restrictions will allow) that gets you the percent power you want.

Combined with the Savvy info above (assuming no prop restriction), let’s say 22/2400 gave you 75% power at whatever altitude. Using the chart/app, you see that 25/2000 also gives you 75% power. You should choose the over square, low rpm setting vs the under square, high rpm, for the host of reasons in the Savvy presentation.

Very cool app, thanks

Normally aspirated is the key

Light Plane Maintenance was a magazine I used to enjoy when it was published. Engine operation recommendations were much akin to information people are getting from Mike Busch these days. They said there should be no term "over squared operations" in a normally aspirated engine in the sense they must be avoided. Every takeoff is that way given the manifold pressure goes up to the 29-30 inch range while all our Lycomings are limited to 2700 RPM. It's more so in a fixed pitch prop aircraft as initial RPM is more likely 2200 or so.

Light Plane Maintenance was a magazine I used to enjoy when it was published. Engine operation recommendations were much akin to information people are getting from Mike Busch these days. They said there should be no term "over squared operations" in a normally aspirated engine in the sense they must be avoided. Every takeoff is that way given the manifold pressure goes up to the 29-30 inch range while all our Lycomings are limited to 2700 RPM. It's more so in a fixed pitch prop aircraft as initial RPM is more likely 2200 or so.

Last edited:

Look at the roots, a different perspective

If pressure had been in PSI, inH2O, millibars, pascals....

If rotational speed basis had been radians/x, hertz, ....

Would this myth have even been started since the associated numbers wouldn't conveniently line up? The validity of the over square myth was disproved a long time ago.

Side question; did "prop forward/throttle back" come from trying to avoid the over-square mythical danger zone? Avoid potential overspeed from sloppy governors?

I still do it mostly from muscle memory. It also keeps any related questions away.

If pressure had been in PSI, inH2O, millibars, pascals....

If rotational speed basis had been radians/x, hertz, ....

Would this myth have even been started since the associated numbers wouldn't conveniently line up? The validity of the over square myth was disproved a long time ago.

Side question; did "prop forward/throttle back" come from trying to avoid the over-square mythical danger zone? Avoid potential overspeed from sloppy governors?

I still do it mostly from muscle memory. It also keeps any related questions away.

If pressure had been in PSI, inH2O, millibars, pascals....

If rotational speed basis had been radians/x, hertz, ....

Would this myth have even been started since the associated numbers wouldn't conveniently line up? The validity of the over square myth was disproved a long time ago.

Side question; did "prop forward/throttle back" come from trying to avoid the over-square mythical danger zone? Avoid potential overspeed from sloppy governors?

I still do it mostly from muscle memory. It also keeps any related questions away.

It is my belief that the old radial engines suffered problems when lugging or heavily loaded (think trying to accelerate in a car without downshifting) and this is where the over square stuff came from. Pushing the prop in, increases RPM and reduces the load on the engine. It is akin to down shifting before accelerating in a car. No problems loading the modern boxer engines, therefore no need to do this, though it hurts nothing to do it.

turbos are ALWAYS over square in a direct drive engine, so this type of mnemonic would have made no sense. Those guys MUST understand their charts and follow the MAP gauge religiously, excluding the more benign turbo normalized set ups.

Larry

Last edited:

thanks, as I read that chart you can run essentially any amount oversquared to a RPM as low as 2,000. Anybody else read this differently?

That's what it says. However, see the empty text block?

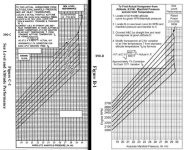

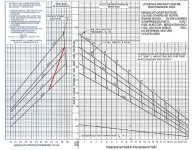

In the mid 2000's, the 390 was a Lycoming kit motor sold through a few selected engine shops. Lycoming published a very thin operating manual, which included a power chart. That chart plotted only five RPM settings, and conspicuously, did not include a feature standard on previous charts, the "Maximum Manifold Pressure For Continuous Operation" line. It didn't even include the text block.

I called Williamsport, and was told (to wit) "We haven't gotten around to it yet, but we probably will if/when it goes to certification". Not unreasonable for an engine shop special.

So fast forward 15 years. We have the 390-C and D, certified and EXP, with new charts. On the C chart, the old limiting manifold pressure block is back, but blank, and no line. The D chart skips it entirely, like the original kit chart.

Consider the older engines. I've attached charts for 320, 360 parallel valve, 360 angle valve, and a 540 angle valve, all from the most current AEIO Operating Manual, which you can download from Lycoming. All include the limiting manifold pressure line.

So, what to do? I have no heartache with oversquare operation, with the caveat that propeller limitations, published or unpublished, should also be considered. However, I will be staying away from a self-imposed limiting manifold pressure line which mimics the classic charts. If the limit line had validity for the previous engines, there is absolutely no reason to think it's not valid for the 390, which runs a bit higher CR.

.

Attachments

Av8rRob

Well Known Member

Dan, Exactly. Thanks for adding some background and data for other types. I guess my takeaway is keep the over squared operation below about 5". It is interesting how the other (non-390 charts) have an angle at the right of the chart and the -390s line is pretty much vertical.

Last edited:

Dan, Exactly. Thanks for adding some background and data for other types.

I was amused to see your post appear when I hit send. Great minds and all that rot...

It is interesting how the other (non-390 charts) have an angle at the right of the chart and the -390s line is pretty much vertical.

The ~vertical line around 29" MP is simply WOT manifold pressure at sea level if the blue knob was pulled to each RPM of interest. Looking at the 360-A, and factoring for a slightly higher CR, a limit line might be as plotted on this early 390A chart.

.

Attachments

Untainted123

Well Known Member

I am just wondering (the technical/mechanic side) what is the harm if manifold (air) is more than RPM by the greater number in these charts.

I assume the air/fuel mixture is correct, lets say at 28" and the RPM is 1600. What happens in the engine that causes harm?

I _think_ the point of this discussion is that the Lycoming chart and anecdotal (Savvy) evidence suggests there is no harm, and that there actually may be quite a bit of benefit to run it as much over square as the prop and charts allow.

I don't know what power percentage 28/1600 gets you, so it may only be 45% power or whatever based on the chart, but there doesn't seem to be harm to it per se.

It sounds like DH is suggesting that Lycoming probably should have made a RPM -> MAP limit line in the 390 specific chart (like they did on the others), but didn't; so he extrapolated his own (the red line bottom right), and that based on that, 28/1600 would indeed be too much "over square" based on his extrapolated chart.

The app I mentioned earlier (by James Petty, which my understanding is that he is (was?) some sort of expert in this area) seems to be making the interpretation that you can't run continuous below 2000 (prop restrictions notwithstanding), since none of the charts plot anything below a 2000rpm line.

So for that reason, assuming you weren't just picking 2 numbers out of thin air as an example, you shouldn't run continuous below 2000rpm at any MAP.

I am learning a lot in this area myself, so I could be off, and defer to much greater minds

Last edited:

So for that reason, assuming you weren't just picking 2 numbers out of thin air as an example, you shouldn't run continuous below 2000rpm at any MAP.

I am learning a lot in this area myself, so I could be off, and defer to much greater minds

I was pulling those numbers out of thin air and exaggerated on the numbers to make the question clear. So given that number and understanding the chart doesn't have this, what happens in the combustion chamber, or the engine that could harm the engine in these scenario?

Bill Boyd

Well Known Member

I'll toss my guess in the hat before the authorities return to give us the answer: it has something to do with mechanical breakdown of the oil film in the bearings that the crank and con rods ride on instead of metal-to-metal. That oil squish-out force would be higher at higher MAP/cylinder pressures under high load/low rpm conditions.

I'm basing that guess on something I recall reading in the Sac Sky Ranch manual long ago. But I'm no authority, given that I only bought the book to learn the secrets of prop re-clocking

I'm basing that guess on something I recall reading in the Sac Sky Ranch manual long ago. But I'm no authority, given that I only bought the book to learn the secrets of prop re-clocking

If pressure had been in PSI, inH2O, millibars, pascals....

If rotational speed basis had been radians/x, hertz, ....

Would this myth have even been started since the associated numbers wouldn't conveniently line up? The validity of the over square myth was disproved a long time ago.

I like the furlongs/firkin/fortnight system, myself.

I am just wondering (the technical/mechanic side) what is the harm if manifold (air) is more than RPM by the greater number in these charts.

I assume the air/fuel mixture is correct, lets say at 28" and the RPM is 1600. What happens in the engine that causes harm?

Improper gearing (i.e. high output/low RPM with short gears) is hard on the engine mechanical components and is also more detonation prone.

Hop on you bike and set up the gearing for a good compromise in speed and pedal effort. Then upshift two gears and try to maintain the same speed without accelerating. Won't take long for your legs to hurt from the exertion even though maintaining that same speed with the correct gears didn't hurt your legs. Same thing happens in crankshaft, connecting rods, bearings, etc. The bigger issue is detonation. High load is detonation prone. Did you drive in the late 70's post leaded gas, before the designers figured out how to deal with the lower octane? if you drove up an incline and your transmission didn't downshift correctly or you didn't force it to downshift with throttle, you would hear marbles rattling in the engine. That is detonation caused by excessive load. They called it "Pinging" at the time, but it is detonation.

Larry

Last edited:

larry, Good way of explaining it, thank you. Both the bicycle and 70's car example make the light bulb in my head go on much better, so thank you.Improper gearing (i.e. high output/low RPM with short gears) is hard on the engine mechanical components and is also more detonation prone.

Hop on you bike and set up the gearing for a good compromise in speed and pedal effort. Then upshift two gears and try to maintain the same speed without accelerating. Won't take long for your legs to hurt from the exertion even though maintaining that same speed with the correct gears didn't hurt your legs. Same thing happens in crankshaft, connecting rods, bearings, etc. The bigger issue is detonation. High load is detonation prone. Did you drive in the late 70's post leaded gas, before the designers figured out how to deal with the lower octane? if you drove up an incline and your transmission didn't downshift correctly or you didn't force it to downshift with throttle, you would hear marbles rattling in the engine. That is detonation caused by excessive load. They called it "Pinging" at the time, but it is detonation.

Larry

They called it "Pinging" at the time, but it is detonation.

I can still hear my Dad yelling at my mom when she got halfway up the hill to our house; "Don't lug the engine Peg!!!"

It seems to me that "LOAD" is accepted as the cause of the detonation. Maybe it can be replaced by torque.

Why would a high torque promote detonation?

Possibly the detonation occurs due to the fixed advance which allows, at low engine speeds, the pressure in the combustion chamber to build up before top dead centre, giving the mixture time to detonate.

Imagining the propagation speed of the flame constant, it is not, it depends on pressure, temperature, air/fuel ratio, etc., to avoid detonation you have to reduce the advance as the revs decrease or, this seems to me the main reason for the pressure limit at low engine speeds, reduce the mixture pressure during the compression stroke to reduce the flames propagation speed.

If the engine doesn't have electronic ignition which reduces the advance I would respect Dan's redline.

Claudio

Why would a high torque promote detonation?

Possibly the detonation occurs due to the fixed advance which allows, at low engine speeds, the pressure in the combustion chamber to build up before top dead centre, giving the mixture time to detonate.

Imagining the propagation speed of the flame constant, it is not, it depends on pressure, temperature, air/fuel ratio, etc., to avoid detonation you have to reduce the advance as the revs decrease or, this seems to me the main reason for the pressure limit at low engine speeds, reduce the mixture pressure during the compression stroke to reduce the flames propagation speed.

If the engine doesn't have electronic ignition which reduces the advance I would respect Dan's redline.

Claudio

It seems to me that "LOAD" is accepted as the cause of the detonation. Maybe it can be replaced by torque.

Why would a high torque promote detonation?

Possibly the detonation occurs due to the fixed advance which allows, at low engine speeds, the pressure in the combustion chamber to build up before top dead centre, giving the mixture time to detonate.

Imagining the propagation speed of the flame constant, it is not, it depends on pressure, temperature, air/fuel ratio, etc., to avoid detonation you have to reduce the advance as the revs decrease or, this seems to me the main reason for the pressure limit at low engine speeds, reduce the mixture pressure during the compression stroke to reduce the flames propagation speed.

If the engine doesn't have electronic ignition which reduces the advance I would respect Dan's redline.

Claudio

While detonation is more likely at max torque, there is MUCH more to detonation than just torque. Load and torque do not necessarily go hand in hand, as torque is just an output measurement. In my example above about going uphill, the detonation is happening nowhere near peak torque. Lugging is more about restricting the crankshaft from accepting the torque applied by the expanding gas in the chamber and transferred to the pistons/conn rods. When you apply too much restriction to the crankshaft, the piston cannot move as quickly as the combusting gas is trying to move it. (large generalization here) This is one of the biggest detonation promoters, although in a well designed engine it can handle a lot of it without the other promoters, such as heat, mixture, advance, etc. Chamber design is also a big factor in how detonation prone an engine will be and why they have changed so much since the 70's (lyc excluded of course).

Advance is all about making sure that peak pressure occurs at the optimum position AFTER TDC (if it occurs before TDC, it is the worst kind of lugging). While further retarding advance can help with detonation, if you lug any engine enough, it can detonate. The amount of peak pressure is a factor, but the bigger factor is WHERE peak pressure occurs (it is a dynamic thing, as everything is moving while it is happening). Lugging increases peak pressure, as the restricted piston doesn't move as quick as the gas is expanding, creating a higher pressure. Another large generalization, as many things are happening, but generally too little piston speed with too much combustion pressure = detonation ( Heat further exacerbates this). This is one of the reasons that most tables increase advance with RPM.

Larry

Last edited: