It's one of those questions which pops up on a regular basis: How do you get a nice edge where fiberglass overlaps plexiglass?

You do it with plastic tape. I use 3m Fineline tape.

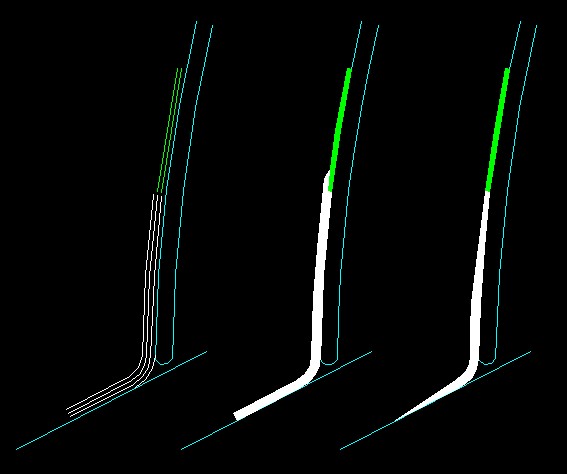

Lay down a tape line on the plexi precisely where you want the glass edge (green, in drawing below). If it's not straight or perfectly positioned just pull it off and do it again. Tape is cheap.

When you have the first tape layer on and positioned where you want it, go back and lay another ply of tape exactly on top of the first. Depending on the thickness of the tape you may want a third layer too. The total thickness of the tape buildup determines the thickness of the subsequent fiberglass edge.

Now do the fiberglass cloth layups. Butt them up close to the tape. Paint a little excess epoxy at the butt so any gap between tape and glass fabric is filled. The glass layups will be thicker than the tape line. The wet epoxy edge should lap over the tape. Allow full cure.

Make up a little sanding block, maybe 6" long and 1" wide, whatever is comfortable and fits the work. Stick 120 grit paper to it and start sanding carefully along the butt joint. Your goal is to sand the new glasswork down to the thickness of the tape. Stop when the tape edge becomes fully exposed. Do not sand into the tape.

When you peel the tape you'll have a defined edge with a consistent thickness.

You do it with plastic tape. I use 3m Fineline tape.

Lay down a tape line on the plexi precisely where you want the glass edge (green, in drawing below). If it's not straight or perfectly positioned just pull it off and do it again. Tape is cheap.

When you have the first tape layer on and positioned where you want it, go back and lay another ply of tape exactly on top of the first. Depending on the thickness of the tape you may want a third layer too. The total thickness of the tape buildup determines the thickness of the subsequent fiberglass edge.

Now do the fiberglass cloth layups. Butt them up close to the tape. Paint a little excess epoxy at the butt so any gap between tape and glass fabric is filled. The glass layups will be thicker than the tape line. The wet epoxy edge should lap over the tape. Allow full cure.

Make up a little sanding block, maybe 6" long and 1" wide, whatever is comfortable and fits the work. Stick 120 grit paper to it and start sanding carefully along the butt joint. Your goal is to sand the new glasswork down to the thickness of the tape. Stop when the tape edge becomes fully exposed. Do not sand into the tape.

When you peel the tape you'll have a defined edge with a consistent thickness.

Last edited: