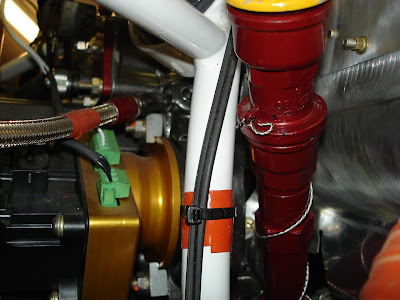

I have a TMXO360 and there is very little clearance between the top of the oil filler neck and the engine mount. This needs to be fixed.

I don't expect that this is the first RV-8/TMXO360 to encounter that problem. Is there a longer/shorter neck option that will address this problem?

Thanks in advance for any suggestions.

I don't expect that this is the first RV-8/TMXO360 to encounter that problem. Is there a longer/shorter neck option that will address this problem?

Thanks in advance for any suggestions.