BobbyLucas

Well Known Member

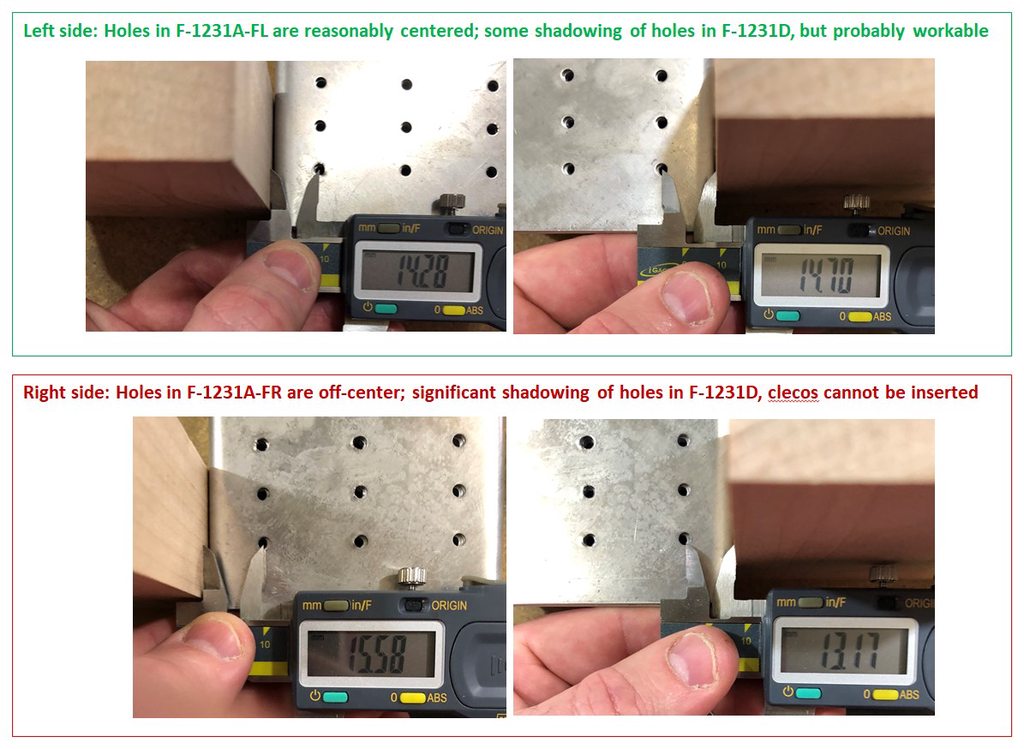

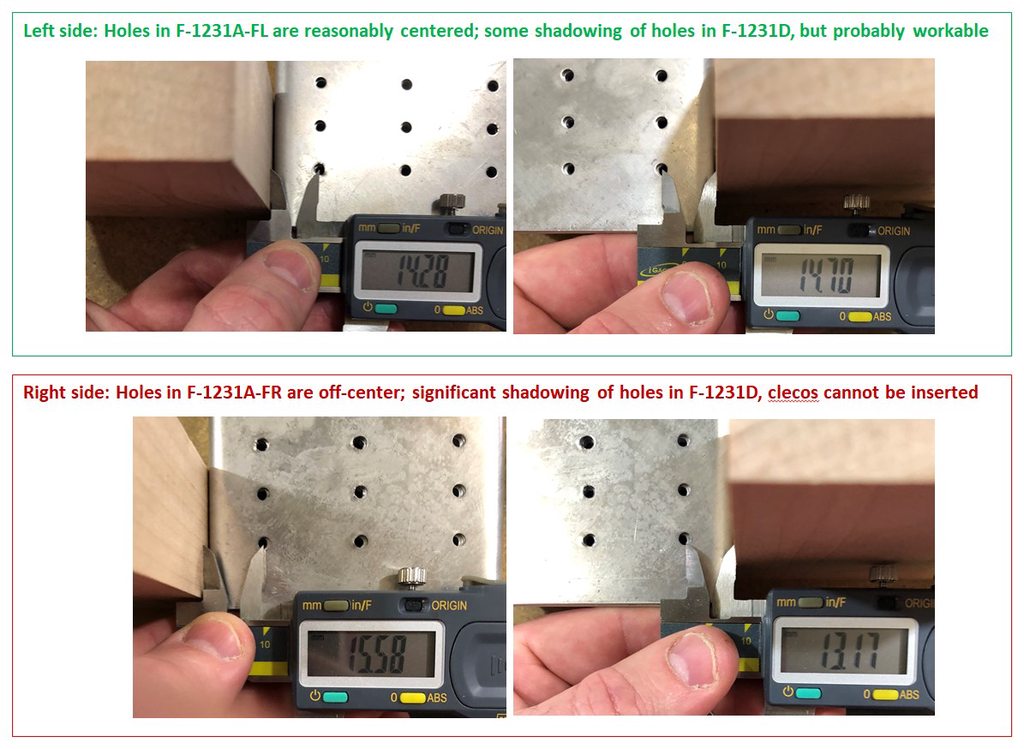

I got the rollover structure all clecoed together and slid onto the bases(attached to fuse) without any issue, but when I went to cleco the structure to the bases, I found one side was so bad that the clecos could not be "persuaded" into more than one hole, all others were too badly shadowed. I brought all the parts back to the bench for measuring and found that the base-attach holes in the right side roll bar were significantly off-center.

Obviously I'll send a note to Van's, but has anyone else run into this?

Obviously I'll send a note to Van's, but has anyone else run into this?