Just so people are aware of potential issue.

I have an RV9, that I didn't build. I bought it with 183 hours, and have put another 150 on since purchase.

The builder did not put any heat shielding on the lower cowl.

I flew it with just the smallest dark spot on the left lower cowl for most of the 150

Hours. The cowling was fine at annual 2 months ago.

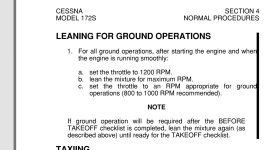

I had an issue with fouling spark plugs during taxi, delayed take offs (busy airport).

After reading a bit, there seemed to be consensus that you can lean quite a bit at idle without problem. I did this for the next several flights.

I recently installed all of my egt and cht gauges, and when I went to put the cowl back on I saw these two huge bubbles where the inner fiberglass layers swelled up like balloons from the honeycomb structure underneath.

After some help from my hangar mate, I removed the old fiberglass and repaired the cowling as best we could. Needless to say heat shield was added.

Looking at it, there seem to be two small areas where the exhaust actually contacts the cowling. Huh!

Just posting this so people are aware what can happen with leaning (apparently too much) at idle.

I have an RV9, that I didn't build. I bought it with 183 hours, and have put another 150 on since purchase.

The builder did not put any heat shielding on the lower cowl.

I flew it with just the smallest dark spot on the left lower cowl for most of the 150

Hours. The cowling was fine at annual 2 months ago.

I had an issue with fouling spark plugs during taxi, delayed take offs (busy airport).

After reading a bit, there seemed to be consensus that you can lean quite a bit at idle without problem. I did this for the next several flights.

I recently installed all of my egt and cht gauges, and when I went to put the cowl back on I saw these two huge bubbles where the inner fiberglass layers swelled up like balloons from the honeycomb structure underneath.

After some help from my hangar mate, I removed the old fiberglass and repaired the cowling as best we could. Needless to say heat shield was added.

Looking at it, there seem to be two small areas where the exhaust actually contacts the cowling. Huh!

Just posting this so people are aware what can happen with leaning (apparently too much) at idle.

Attachments

Last edited: