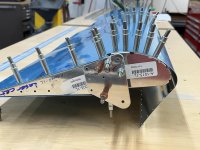

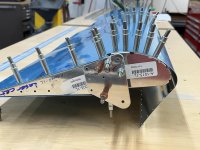

When this Nose Skin is clecoed to the A-1003-1L Spar on one edge the other edge needs to be flexed 3-1/2" to meet the spar. This can easily be done but requires significant force to do it. I don't know what this stress will do to the final assembled shape because this is as far as I have gone. Is this normal? What have others seen here?