Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cotter pin Beringer 5” wheels

- Thread starter JDA_BTR

- Start date

dgustafson

I'm New Here

Ms24665-304 looks right to me. 3/32 x 1-1/4.

dmattmul

Well Known Member

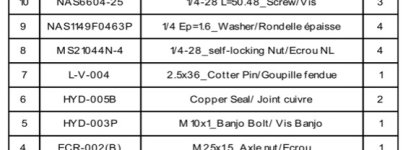

L-V-004 Cotter Pin Specs.

Going through my last brake pad and tire replacement (425 hrs.) these are from my notes. Beringer calls out this part as 2.5*36 mm so I think 3/32th would be ok. 1 1/4" would be 31.75mm but their appeared to be 3 or 4 mm that the existing pin could be shortened and still have room to properly bend over. I ordered said cotter pin from ACS and will inspect and replace next time wheel pants are removed (~ every 6 months). Beringer does recommend replacement each time the cotter pin is removed. Most likely they are being cautious as this pin is the only method the wheel nut is secured as they instruct one to hand tighten their wheel nut only. My wheel nuts typically loosen until it hits the cotter pin. (About 1/8 turn until it hits the pin) What secures the wheel from moving out at all is the disk brake safety wire. Beringer calls out 1 mm and would recommend 041 be used, nothing smaller. Also, it helps to use a pair of hemostats to hold the wire in place while safety tying it.

Going through my last brake pad and tire replacement (425 hrs.) these are from my notes. Beringer calls out this part as 2.5*36 mm so I think 3/32th would be ok. 1 1/4" would be 31.75mm but their appeared to be 3 or 4 mm that the existing pin could be shortened and still have room to properly bend over. I ordered said cotter pin from ACS and will inspect and replace next time wheel pants are removed (~ every 6 months). Beringer does recommend replacement each time the cotter pin is removed. Most likely they are being cautious as this pin is the only method the wheel nut is secured as they instruct one to hand tighten their wheel nut only. My wheel nuts typically loosen until it hits the cotter pin. (About 1/8 turn until it hits the pin) What secures the wheel from moving out at all is the disk brake safety wire. Beringer calls out 1 mm and would recommend 041 be used, nothing smaller. Also, it helps to use a pair of hemostats to hold the wire in place while safety tying it.

Attachments

Last edited:

MED

Well Known Member

Beringer calls out this part as 2.5*36 mm so I think 3/16th would be ok.

2.5 mm is 0.098 inch, so 3/16 (0.1875 inch) might be too big. 1/8 (0.125 inch) might fit. I just order a pack of 10 of the correct size from Beringer to be sure.

dmattmul

Well Known Member

Corrected

Med, I corrected it to the cotter pin size in question which was 3/32nd shortly after posting. Thanks

2.5 mm is 0.098 inch, so 3/16 (0.1875 inch) might be too big. 1/8 (0.125 inch) might fit. I just order a pack of 10 of the correct size from Beringer to be sure.

Med, I corrected it to the cotter pin size in question which was 3/32nd shortly after posting. Thanks

The axle nut is actually should be torqued and if memory serves me right, it is 220 in/lb for the axle nut. It is part of their instruction which it is rather poorly distributed.Most likely they are being cautious as this pin is the only method the wheel nut is secured as they instruct one to hand tighten their wheel nut only.

dmattmul

Well Known Member

Glad you brought this up

This is the page that I thought instructed me to hand tighten only. I am not sure I have a socket that could get on this nut. It would need to be a very thin wall socket and very deep. My 10 has a round nut (mini-splined) with no flats so not sure how to torque that. From the beginning I have just hand tightened this nut. Unlike Beringer not to make this perfectly clear. Normally their documentation is almost anal.

The axle nut is actually should be torqued and if memory serves me right, it is 220 in/lb for the axle nut. It is part of their instruction which it is rather poorly distributed.

This is the page that I thought instructed me to hand tighten only. I am not sure I have a socket that could get on this nut. It would need to be a very thin wall socket and very deep. My 10 has a round nut (mini-splined) with no flats so not sure how to torque that. From the beginning I have just hand tightened this nut. Unlike Beringer not to make this perfectly clear. Normally their documentation is almost anal.

Attachments

dmattmul

Well Known Member

Previous thread by Rockitdoc

"I just spoke to Beringer tech. The axle nut is indeed supposed to be torqued to 220 in-lbs. The bearings are captured inside the hub by snap rings, so they don't know the nut is torqued. The torque is specified simply as a safety measure to assure there is enough 'snugness' to get the cotter pin inserted through the spindle and to provide a standard torque spec for all builders. Finger tight is fine as long as the cotter pin can be inserted."

I would not want to put 220 in-lbs on that lightweight nut. Finger tight is all that is needed to get the cotter pin in.

Read Walts comments:

https://vansairforce.net/community/showthread.php?t=201789&highlight=beringer+axle

"I just spoke to Beringer tech. The axle nut is indeed supposed to be torqued to 220 in-lbs. The bearings are captured inside the hub by snap rings, so they don't know the nut is torqued. The torque is specified simply as a safety measure to assure there is enough 'snugness' to get the cotter pin inserted through the spindle and to provide a standard torque spec for all builders. Finger tight is fine as long as the cotter pin can be inserted."

I would not want to put 220 in-lbs on that lightweight nut. Finger tight is all that is needed to get the cotter pin in.

Read Walts comments:

https://vansairforce.net/community/showthread.php?t=201789&highlight=beringer+axle

Last edited:

This is the page that I thought instructed me to hand tighten only. I am not sure I have a socket that could get on this nut. It would need to be a very thin wall socket and very deep. My 10 has a round nut (mini-splined) with no flats so not sure how to torque that. From the beginning I have just hand tightened this nut. Unlike Beringer not to make this perfectly clear. Normally their documentation is almost anal.

This works perfectly and I have used it multiple times without any issues.

https://www.amazon.com/gp/product/B005VNLH6C/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

dmattmul

Well Known Member

Good site for quality metric parts

https://www.accu.co.uk/

For those needing high quality metric parts and a great selection this is a good sight to order from. (I still order a decent number of parts for my side job) Yes, they have Beringer cotter pins to their exact spec. Good service (less than one week shipping) parts are reasonable, but shipping is a little on the high side.

https://www.accu.co.uk/

For those needing high quality metric parts and a great selection this is a good sight to order from. (I still order a decent number of parts for my side job) Yes, they have Beringer cotter pins to their exact spec. Good service (less than one week shipping) parts are reasonable, but shipping is a little on the high side.

dmattmul

Well Known Member

Cotter Pin for 5 in Beringer wheel

Pic of a MS cotter pin from ACS and the one that Beringer specifies. Although I have not tried either one looking at the needed length when I changed my brake pads and tires believe the MS one would be fine. Results may vary. (The longer one is the metric version)

Pic of a MS cotter pin from ACS and the one that Beringer specifies. Although I have not tried either one looking at the needed length when I changed my brake pads and tires believe the MS one would be fine. Results may vary. (The longer one is the metric version)