ron sterba

Well Known Member

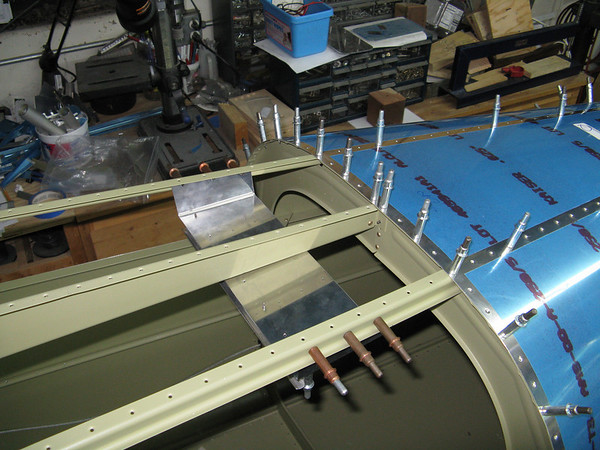

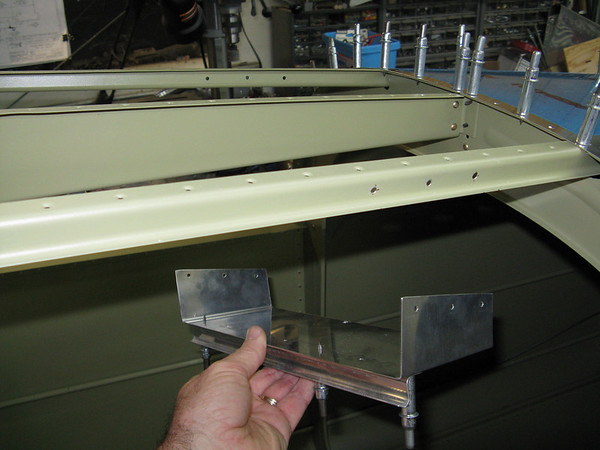

Just installed my static ports on my RV9A and routed my static tubing to the F707 bulkhead where I need to build a tray for my ADAHRS (All Dads Aim Higher Rock Solid) almost sounds like (A HEARTS) made up a little sentance to remember ADAHRS. OR if you have a better jingle to jog the memory lets hear it! If anybody who has installed that tray and has a picture that would be cool too! Was wondering about hanging it from the top of the bulkhead or build a bracket across the stringers with some 3 quarter inch angle and a tray to the dimensions in Dynon PDF to a tray for the ADAHRS. Ron

Last edited: