PerfTech

Well Known Member

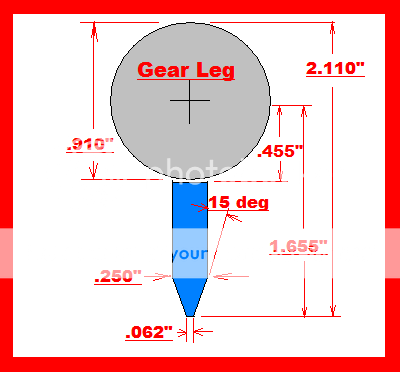

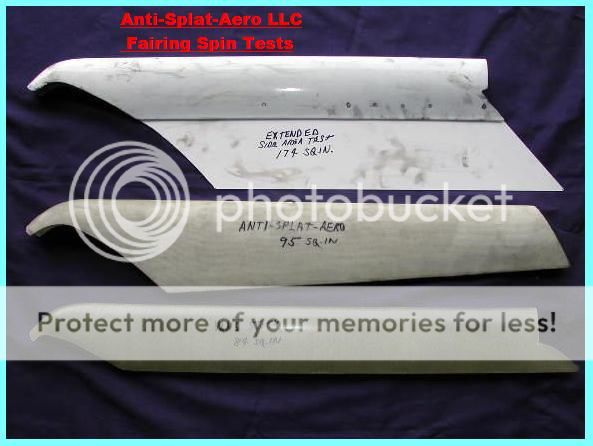

....We have created a new model of "The Nose Job" by popular demand and now have them available. We now have a version of this very popular product that fits inside the stock Vans nose gear fairings, thus eliminating the retro fitting of a new fairing, hinges, glass work, filling and painting Etc.

I never really gave it a lot of thought, but we were continually asked if it will fit in the original fairing? I guess if I had my airplane all finished, painted and flying with the countless hours of work involved I would be reluctant an resistant to changing it. So, here it is, no modification necessary and it takes only a few minutes to install. Now the best part, IT'S CHEAPER!, yes CHEAPER! About $40 less and hours less work to install as well. I am sorry we didn't offer this sooner, I guess I wasn't listen well enough. You guys need to remember, I'm getting old, you need to complain loudly. Thanks all, Allan ..

I never really gave it a lot of thought, but we were continually asked if it will fit in the original fairing? I guess if I had my airplane all finished, painted and flying with the countless hours of work involved I would be reluctant an resistant to changing it. So, here it is, no modification necessary and it takes only a few minutes to install. Now the best part, IT'S CHEAPER!, yes CHEAPER! About $40 less and hours less work to install as well. I am sorry we didn't offer this sooner, I guess I wasn't listen well enough. You guys need to remember, I'm getting old, you need to complain loudly. Thanks all, Allan ..

Last edited: