For those of you who have P-Mags in your plane, how did you route the blast tubes for cooling? I have an RV-9A with an O-320. Mostly I'm interested in how you fixed the position of the tube right at the P-Mag. there's not much around there to hook it to. Pictures would be great. Thanks!

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blast tubes to P-Mags

- Thread starter BruceP

- Start date

RetiredRacer

Well Known Member

I just put a hole in the rear of the baffle, one each side directly above each P-Mag for the blast tubes. And then zip tied the tubes to the engine mount, directing the blast onto the base of the P-Mags. I was a little concerned that the movement of the engine might dislodge the tubes from the baffle. but the tubes must have enough flex, as in 200 hrs they are still good and doing their job.

Last edited:

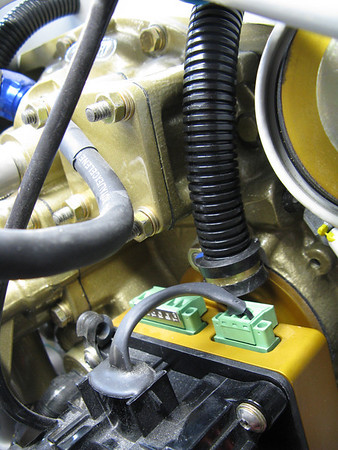

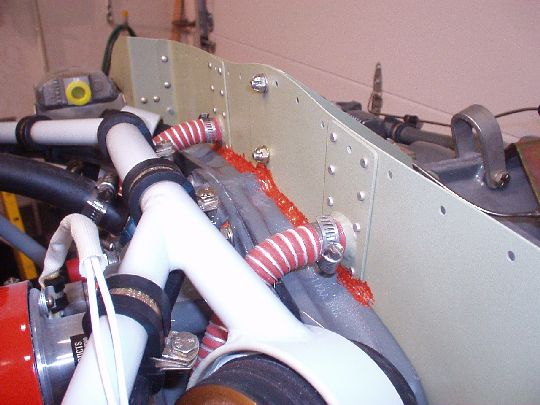

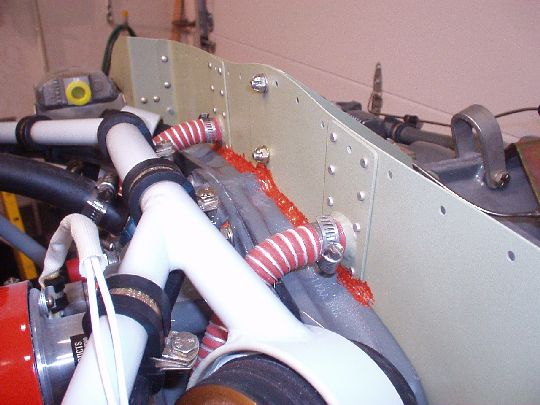

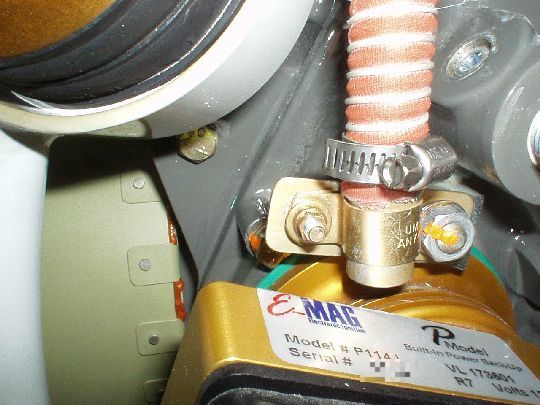

I routed the blast tube (I used 5/8" SCAT ducting) under the engine mount tube, i.e. between the engine mount tube and the accessory case. And it makes contact with neither the engine accessory case nor the engine mount tube. It has about 1/4" clearance to each. See first two photos.

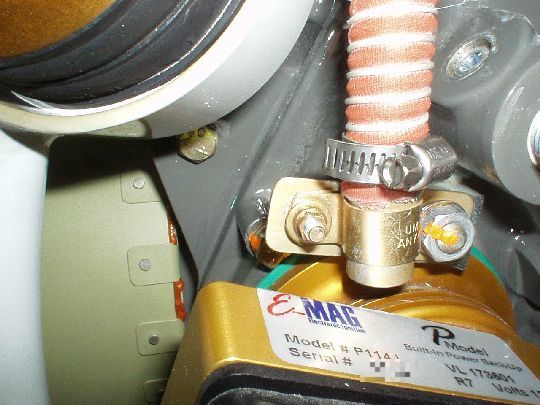

Then, to position the blast tube at the P-Mag end, I made a little fixture that attaches to the engine via the upper magneto clamp stud. This way, both ends of the blast tube are attached to the engine, never to the engine mount, so there is no relative motion to worry about.

The attachment fixture has a handful of parts, but it's quite simple. A little tab of 0.032" sheet aluminum attaches to the upper magneto clamp stud on the engine. Then a short length of 5/8" aluminum tubing is attached to the tab via an aluminum tubing clamp. And finally the SCAT duct is attached to the aluminum tube using a hose clamp. Makes for an installation that's neat, robust, and easily adjustable. See the third photo.

Then, to position the blast tube at the P-Mag end, I made a little fixture that attaches to the engine via the upper magneto clamp stud. This way, both ends of the blast tube are attached to the engine, never to the engine mount, so there is no relative motion to worry about.

The attachment fixture has a handful of parts, but it's quite simple. A little tab of 0.032" sheet aluminum attaches to the upper magneto clamp stud on the engine. Then a short length of 5/8" aluminum tubing is attached to the tab via an aluminum tubing clamp. And finally the SCAT duct is attached to the aluminum tube using a hose clamp. Makes for an installation that's neat, robust, and easily adjustable. See the third photo.

Last edited:

jjconstant

Well Known Member

I ran a piece of safety wire down thru the tube and wrapped it around the Pmag and back up the tube, tied it off and it has worked great.

Oh boy, am I going to steal THAT idea!!! Nice, easy and effective.

RV7AJeremy

Well Known Member

An ignorant question?

Will that plastic conduit tolerate the heat in the engine compartment?

Will that plastic conduit tolerate the heat in the engine compartment?

hydroguy2

Well Known Member

Will that plastic conduit tolerate the heat in the engine compartment?

No problem in my 7

brad walton

Well Known Member

I used the black corrugated tubing Van's supplies for wiring conduit as blast tubes for my two magnetos and my alternator on the RV-8. I attached it with Permatex gasket maker so it does not rotate in the hole through the baffling and shaped it into position to direct the airflow where I wanted it with a heat gun. It seems to hold position just fine and the heat of the engine compartment does not affect it, probably because there is cool air blowing through it. I think I recall this was a recommended usage by Van's.

my 9A was done like this as well (slick mags). 400+ hours. no issues so far.

Will that plastic conduit tolerate the heat in the engine compartment?