lucaperazzolli

Well Known Member

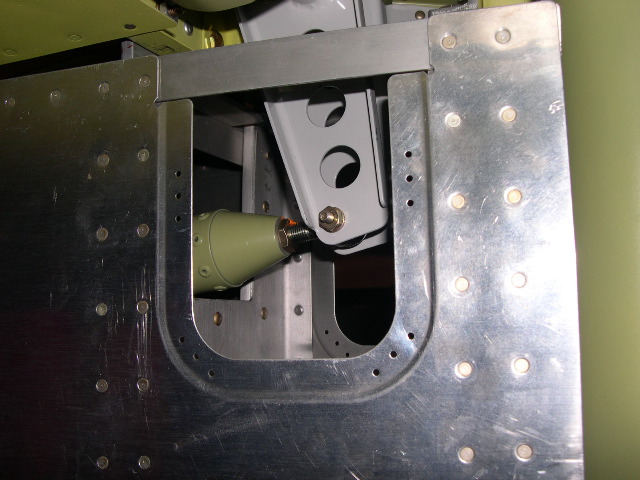

I was thinking about the safety of the elevator and trim function.

My idea : in the rare case that the nut&bolt go off from the elevator horns linkage, the airplane will have two elevators free into the wind

It's ok, the pilot will need to control the pitch with engine and trim...BUT we have the trim tab only in the left elevator

Probably it's supposed (by design) that the pilot will have less pitch control with only one elevator and the other one will stay 'neutral' with no catastrofic event ...

Maybe a simple hole/bolt/spacer/nut between the horns will solve this case.

What's your thought about ?

ps: the nut in the image is a temporary one !

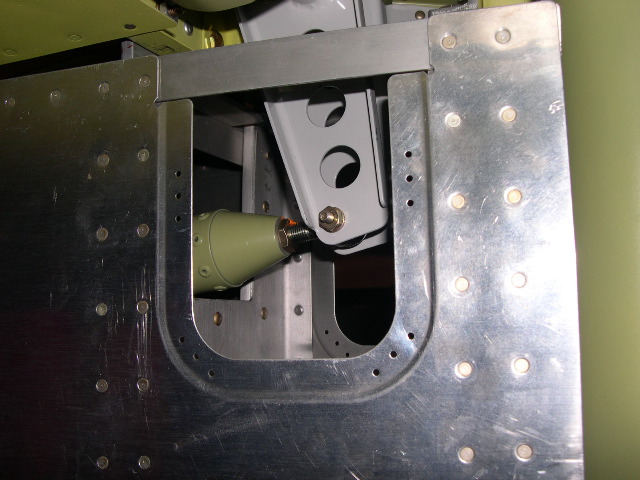

My idea : in the rare case that the nut&bolt go off from the elevator horns linkage, the airplane will have two elevators free into the wind

It's ok, the pilot will need to control the pitch with engine and trim...BUT we have the trim tab only in the left elevator

Probably it's supposed (by design) that the pilot will have less pitch control with only one elevator and the other one will stay 'neutral' with no catastrofic event ...

Maybe a simple hole/bolt/spacer/nut between the horns will solve this case.

What's your thought about ?

ps: the nut in the image is a temporary one !

Last edited: