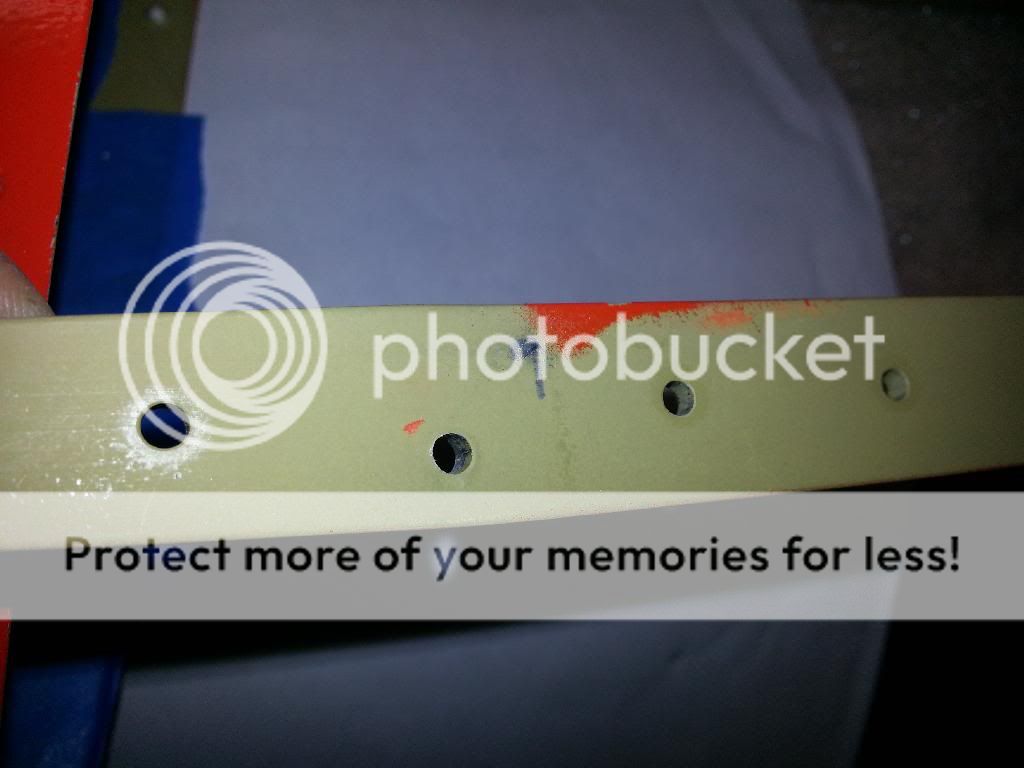

The notch is where ?

So maybe that is some of it. In this picture (as in my 7a) the notch is further outboard and appears to be more centered over the bend line which I think is on the edge of the flange. If the notch is more inboard of that, which many seem to be based on the relationship to the rib flange. It may be that the notch isn't working well in some cases because it is a half inch too far inboard.

Just saying that it seems to me like the notch should be centered on the bend line and many are inboard of that. I think you can see that in many pictures by looking at the location relative to the rib flange. I think this is the way it is supposed to be ..... slightly under the flange.

Of course many are flying fine with no notches at all.

Just thinking out loud ....

Interesting about the position of this "notch". How would one see any potential cracking behind that rib flange? Tough dilemma.

So maybe that is some of it. In this picture (as in my 7a) the notch is further outboard and appears to be more centered over the bend line which I think is on the edge of the flange. If the notch is more inboard of that, which many seem to be based on the relationship to the rib flange. It may be that the notch isn't working well in some cases because it is a half inch too far inboard.

Just saying that it seems to me like the notch should be centered on the bend line and many are inboard of that. I think you can see that in many pictures by looking at the location relative to the rib flange. I think this is the way it is supposed to be ..... slightly under the flange.

Of course many are flying fine with no notches at all.

Just thinking out loud ....