rleffler

Well Known Member

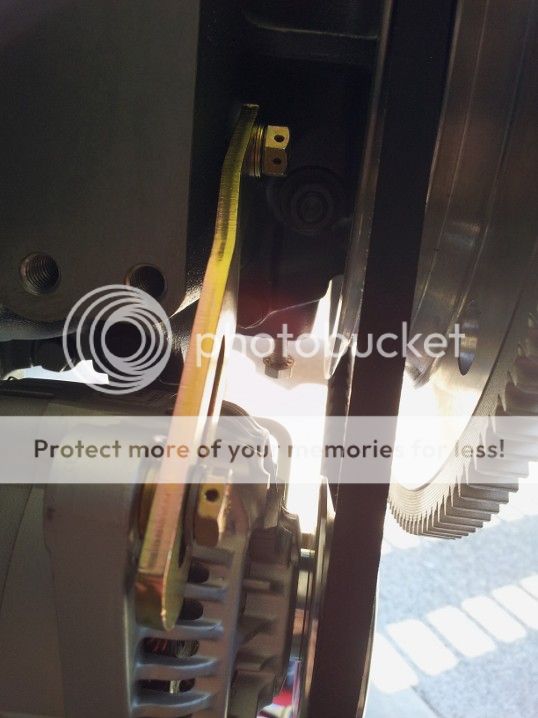

A little over a year or so ago, Van's had Lycoming change the flywheel to a LW-12227 to accomodate a dual belt system to support both the alternator and air conditioning. This part has the alternator belt on the rear and a V shaped groove in front for the A/C.

Myself and several others that purchased a YIO-540-D4A5 and the Firewall Forward kit from Van's have noticed an alignment issue. The Plane Power 60a alternator supplied in the FWF kit from Van's has the alternator about 3/16" forward and prevents proper alignment of the belt.

Plane Power has stated that none of their alternators will work with a dual belted flywheel.

Van's, Plane Power, and Lycoming are currently looking into the issue, so I'm not looking for alternative or creative solutions to this situation. I'm going to let the three companies work through the engineering and come back with a resolution.

What I am looking for is to identify anyone that purchased a YIO-540-D4A5 from Van's in the last two years and the answers to the following questions.

If you don't want your comments to be made public, please PM or email me.

thanks,

bob

Myself and several others that purchased a YIO-540-D4A5 and the Firewall Forward kit from Van's have noticed an alignment issue. The Plane Power 60a alternator supplied in the FWF kit from Van's has the alternator about 3/16" forward and prevents proper alignment of the belt.

Plane Power has stated that none of their alternators will work with a dual belted flywheel.

Van's, Plane Power, and Lycoming are currently looking into the issue, so I'm not looking for alternative or creative solutions to this situation. I'm going to let the three companies work through the engineering and come back with a resolution.

What I am looking for is to identify anyone that purchased a YIO-540-D4A5 from Van's in the last two years and the answers to the following questions.

- Do you have a LW-12227 flywheel or another part (i.e. single belted)?

- Do you have a Plane Power alternator?

- If you have a Plane Power alternator and a LW-12227 did you have an alignment issue?

- If you have a LW-12227 and another brand alternator, did you have an alignment issue?

If you don't want your comments to be made public, please PM or email me.

thanks,

bob