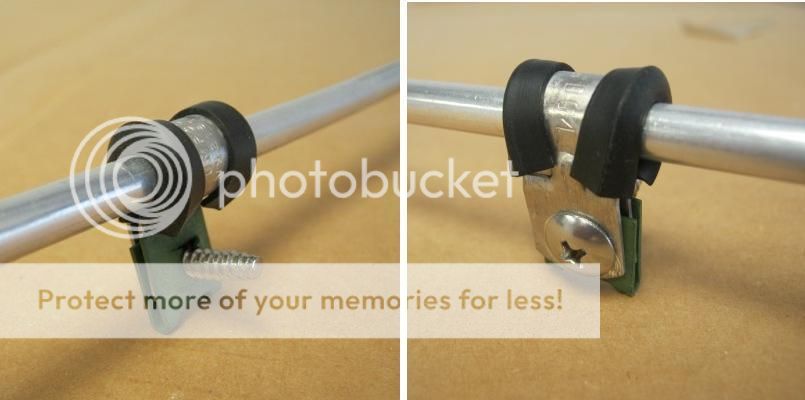

1. Is it acceptable to use tinnerman nuts and sheet metal screws to attach adel clamps to let say a subpanel?

http://www.aircraftspruce.com/catalog/hapages/tinnerman.php

2. Are the grasshooper nuts the way to go to attach gauges to the panel?

http://www.aircraftspruce.com/catalog/inpages/instnuts.php

3. Which method is best-using panel switches with fast-on connectors or screws for ring terminals? Or, put it another way....how hard do the fast-ons separate (after years of use) for fear of yanking out the panel in the process?

Or are these tings Potato Potahto

Thanks for the feedback

Jim

RV9A

working on things electrical

http://www.aircraftspruce.com/catalog/hapages/tinnerman.php

2. Are the grasshooper nuts the way to go to attach gauges to the panel?

http://www.aircraftspruce.com/catalog/inpages/instnuts.php

3. Which method is best-using panel switches with fast-on connectors or screws for ring terminals? Or, put it another way....how hard do the fast-ons separate (after years of use) for fear of yanking out the panel in the process?

Or are these tings Potato Potahto

Thanks for the feedback

Jim

RV9A

working on things electrical

Last edited: