sapeloson

Well Known Member

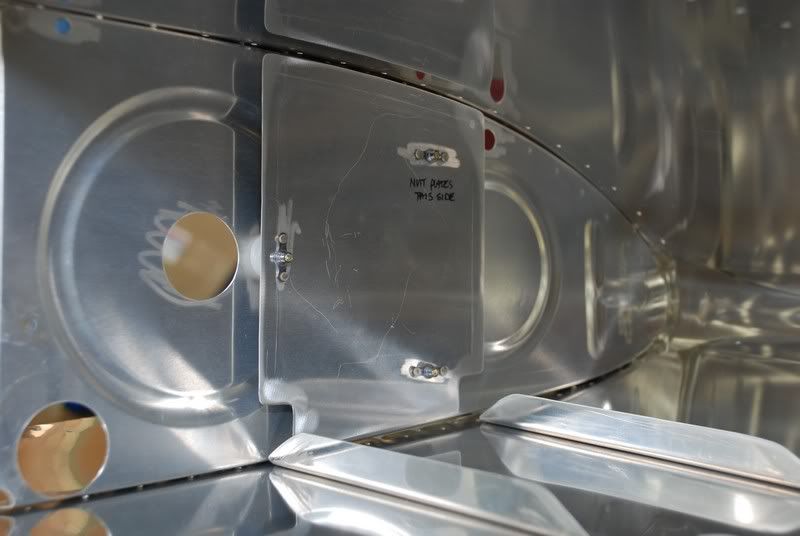

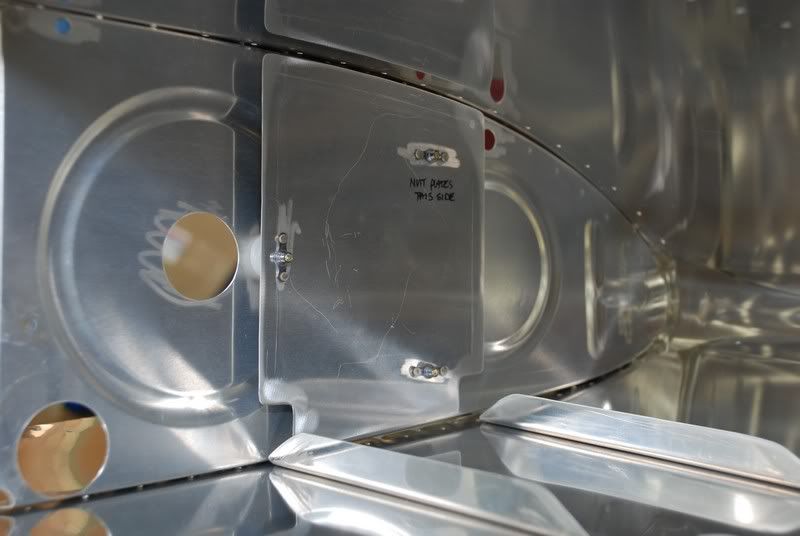

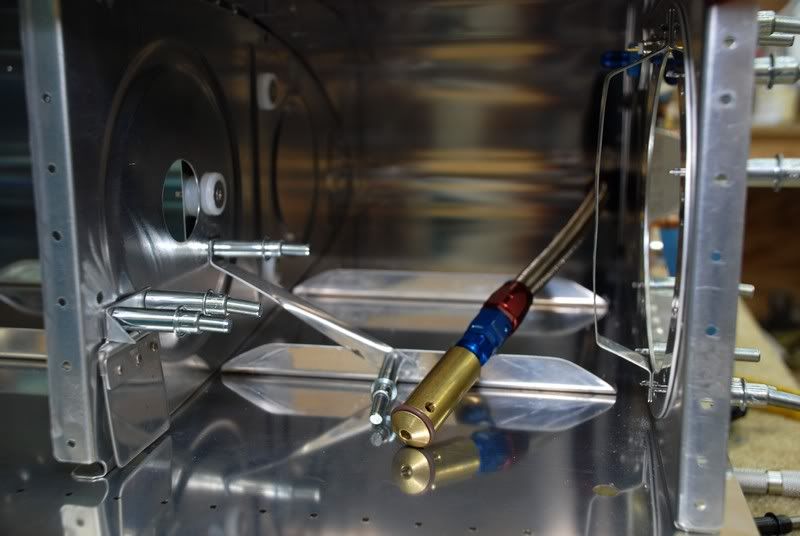

I'm at the point of tank construction where the plans say to "install the capacitive senders if using them", which I am. I have started the sender construction but, something doesn't seem right. The sender instructions say to install the inboard ribs and I haven't even dimpled the skins or installed the stiffeners. It seems like I need to wait a little while and use the plan sequence with the capacitive stuff thrown in later........I'm also using a flop tube in the left tank so I have some inverted stuff to do also. What is the best sequence of construction/installation to use?