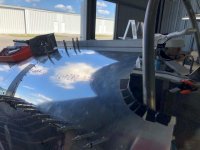

Wasting a lot of aluminum here. The glare shield is a bit “special” as the forward part has to be formed to follow the contour of the airframe while the back most edges are nearly straight to clear the WS bow. Would love to cut down on my scrap and be more efficient. Any wisdom, methods, tricks, whatever anyone could share would be appreciated. Here or PMs, whatever worked for you. Much thanks.

Last edited by a moderator: