Anyone cut both the Tempest and NAPA Gold 1515 open and do a side by side comparison? I would be interested in seeing some pics and also filter housing metal thickness measurements. Maybe even a nice pic of a cross-cut section of the filter housing to flange crimp attachment. I am pretty conservative when it comes to "experimenting" with known aircraft standards, but it looks like the NAPA Gold 1515 has had quite a bit of real world testing to prove it is a viable alternative to a Champion or Tempest filter.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone want to rehash oil filters?

- Thread starter Tram

- Start date

Anyone cut both the Tempest and NAPA Gold 1515 open and do a side by side comparison? I would be interested in seeing some pics and also filter housing metal thickness measurements. Maybe even a nice pic of a cross-cut section of the filter housing to flange crimp attachment. I am pretty conservative when it comes to "experimenting" with known aircraft standards, but it looks like the NAPA Gold 1515 has had quite a bit of real world testing to prove it is a viable alternative to a Champion or Tempest filter.

I would also be curious to compare flow rates. I don't know too many modern cars that use 50 weight oil. My concern would be more about protection of the engine from wear than it would be about failure in flight. Guys saying that they have 300, or 400 hours no problem is great, but what about 2000 hours? I'd like my engine to go at least to TBO and preferably beyond.

rocketbob

Well Known Member

The Wix number for the 1515 is 51515. $3.78 on rockauto.com. The 1515 is the Napa-branded Wix filter. Same exact filter.

Napa Gold 1515 is rated 21 microns.

FAA approved filters are rated 40 microns.

Let that sink in.

I'd venture to guess between the friends that run these filters and the RVs I maintain the number of hours in this sphere has to exceed 20,000 hours. They work well, they trap shavings, they work with 50W oil. If you don't feel comfortable using them, or need proof beyond a reasonable doubt, stick with what you're doing.

Napa Gold 1515 is rated 21 microns.

FAA approved filters are rated 40 microns.

Let that sink in.

I'd venture to guess between the friends that run these filters and the RVs I maintain the number of hours in this sphere has to exceed 20,000 hours. They work well, they trap shavings, they work with 50W oil. If you don't feel comfortable using them, or need proof beyond a reasonable doubt, stick with what you're doing.

rocketbob

Well Known Member

another option

The Baldwin B2-HPG is a another filter I would strongly consider over an aircraft filter. It has a 8 micron nominal rating which is very good. I have not tried one, but have used their bypass filters.

Baldwin is generally considered one of the top filter manufacturers.

The Baldwin B2-HPG is a another filter I would strongly consider over an aircraft filter. It has a 8 micron nominal rating which is very good. I have not tried one, but have used their bypass filters.

Baldwin is generally considered one of the top filter manufacturers.

Lycoming Oil Pressure ++++

I read these posts about oil pressures being set at 100 + PSI on Lycoming Engines, Why? Why in the world would anyone set their pressure above 65 psi. These engines are not making 1000 Horse Power! Rule of thumb for engine designers and builders 10 PSI per 100 HP is sufficient lubrication on the average engine with supporting bearing area. A Lycoming IO 360 will fly around the world on 20 PSI.

What determines required oil pressure is HP and bearing surface area. Our engines have 2 times the surface area of most 300 HP small engines running at 30 to 40 psi. For those of you that are pumping the oil pressure up to 80 + PSI all you are doing is friction heating the oil as it is forced to overcome the by-pass valve. You are also pushing most of the oil through the oil filter by-pass. This is allowing the majority of the oil in the engine to escape the filter element and flow directly to the bearings unfiltered!

For those of you that wish to argue with me I suggest you do some research on engine oil system design.

In addition, those of you running these ridiculously high oil pressures, your concern should be oil temp, oil filtration and possible system failure. You are just creating undue stress on the oil cooler, lines and filter element housing. More is not always better.

General Motors and others used scoop and splash oil systems (0 psi) on their v-8 engines up until most of these Lycomings were flying in the 1960's. Again, lubrication is based on surface area and HP!

I read these posts about oil pressures being set at 100 + PSI on Lycoming Engines, Why? Why in the world would anyone set their pressure above 65 psi. These engines are not making 1000 Horse Power! Rule of thumb for engine designers and builders 10 PSI per 100 HP is sufficient lubrication on the average engine with supporting bearing area. A Lycoming IO 360 will fly around the world on 20 PSI.

What determines required oil pressure is HP and bearing surface area. Our engines have 2 times the surface area of most 300 HP small engines running at 30 to 40 psi. For those of you that are pumping the oil pressure up to 80 + PSI all you are doing is friction heating the oil as it is forced to overcome the by-pass valve. You are also pushing most of the oil through the oil filter by-pass. This is allowing the majority of the oil in the engine to escape the filter element and flow directly to the bearings unfiltered!

For those of you that wish to argue with me I suggest you do some research on engine oil system design.

In addition, those of you running these ridiculously high oil pressures, your concern should be oil temp, oil filtration and possible system failure. You are just creating undue stress on the oil cooler, lines and filter element housing. More is not always better.

General Motors and others used scoop and splash oil systems (0 psi) on their v-8 engines up until most of these Lycomings were flying in the 1960's. Again, lubrication is based on surface area and HP!

rv7charlie

Well Known Member

Well, that and how torturous the path is to the last lube point, and how much they are compensating for sloppy design work...

Ask anyone who's replaced a cam after losing a lobe that lifts opposing valves, or the aftermarket case maker that fixed the around the world oil path in a stock Lyc case.

Ask anyone who's replaced a cam after losing a lobe that lifts opposing valves, or the aftermarket case maker that fixed the around the world oil path in a stock Lyc case.

BillL

Well Known Member

For those of you that wish to argue with me I suggest you do some research on engine oil system design.

I have, but won't be arguing with you, it is not helpful.

Facts:

1. Pressurized oil to bearings is incorporated in designs to keep the bearing journals cool.

2. The design factors for the bearings are force, eccentricity, and shear velocity (related to engine RPM).

3. Forces (peak) could be from inertia (weights of components) or cylinder pressures and the combination of above.

4. The key point for bearings in a pressure supply system is at the bearing entry. Oil to bearing temperature and pressure. Temperature for viscosity of the bearing needs to maintain separation, and pressure to maintain flow to keep the bearings cool.

HP is a factor in some of the design parameters, but only indirectly. Bearings (L/D, diameter) are usually designed using a supply temp (~230F), and 10 psi OTB regardless of anything else.

rocketbob

Well Known Member

For those of you that wish to argue with me I suggest you do some research on engine oil system design.

ok, I'll bite...game on.

Have you ever physically measured the amount of oil being returned from each cylinder?

I have. I removed oil return lines and slung plastic cups with zip ties and validated the right side cylinders get very little oil compared to the left side.

I've set up many engines for 100 PSI cold and have found no detrimental effect. In fact, I've never had problems with these engines.

Yesterday evening, in fact, I was test running an engine I overhauled. At 1800 RPM we were getting 55psi. Way too low. Tonight we're shimming the spring to get at least 75psi warm, and will continue to adjust from there.

OIL PRESSURE 100 +++

I'm not telling anyone not to run high oil pressure. I am stating that there Is no need to ever run anything over 65 psi on a Lycoming Engine.

On a side not I worked as a Powertrain engineer for Chrysler for over 10 years and then another 5 years with Detroit Diesel conducting root cause analysis on engine failures. Oil starvation was rarely a failure mode. Most Chrysler products were running between 20 and 30 PSI. The gages were pre programmed to display a pressure that the customer felt comfortable with, not what the engine was actually producing. As a matter of fact, most automotive engines use an oil pressure switch that is designed to close at 5 psi. They don't use pressure sensors. So long as the switch closes the engine controller will display a pre-programmed pressure on the cluster that keeps people from visiting the dealership complaining about low oil pressure.

Even 65 PSI is Extreme overkill with the large Lycoming crank journals and bearing surface area. Considering that the cam lobes, piston pins and cylinder walls are all splash oiled.

I'm not telling anyone not to run high oil pressure. I am stating that there Is no need to ever run anything over 65 psi on a Lycoming Engine.

On a side not I worked as a Powertrain engineer for Chrysler for over 10 years and then another 5 years with Detroit Diesel conducting root cause analysis on engine failures. Oil starvation was rarely a failure mode. Most Chrysler products were running between 20 and 30 PSI. The gages were pre programmed to display a pressure that the customer felt comfortable with, not what the engine was actually producing. As a matter of fact, most automotive engines use an oil pressure switch that is designed to close at 5 psi. They don't use pressure sensors. So long as the switch closes the engine controller will display a pre-programmed pressure on the cluster that keeps people from visiting the dealership complaining about low oil pressure.

Even 65 PSI is Extreme overkill with the large Lycoming crank journals and bearing surface area. Considering that the cam lobes, piston pins and cylinder walls are all splash oiled.

Rocket Bob is onto it. The reason you need high oil pressure is that the hydraulic lifters were never designed to pass oil up to the top end for valve cooling and so they don't do a good job of it. Lycoming also uses sodium filled valve stems to conduct heat from the edge of the valve back to the guide. That is a good idea, but oil must conduct some of the heat away and there just isn't enough of it up there to do that. Lycoming, in their infinite wisdom, tapped all the oil pressure for cam and crank from the right side, reducing the pressure at the right side lifters further. #3 (and #5) exhaust valve guides wear out first for lack of cooling oil and generally higher temps.

Ed Holyoke

Ed Holyoke

Tomcat RV4

Well Known Member

Any suggestions for Lyc 0-235 as far as filter goes ?

Northernliving

Well Known Member

Comps

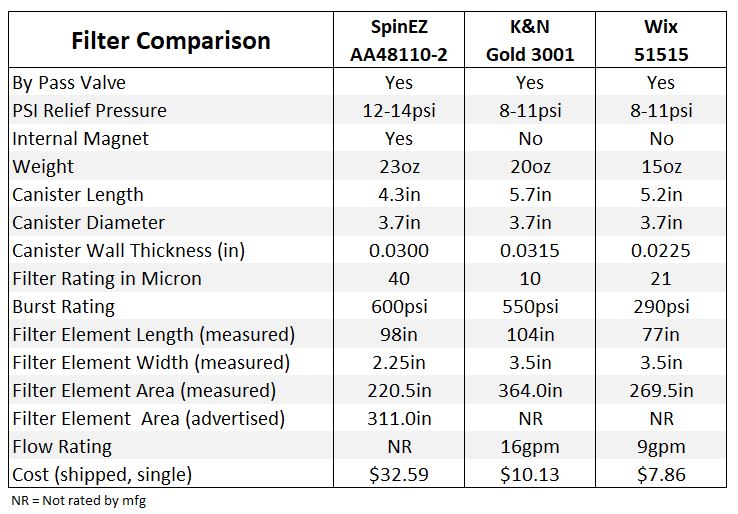

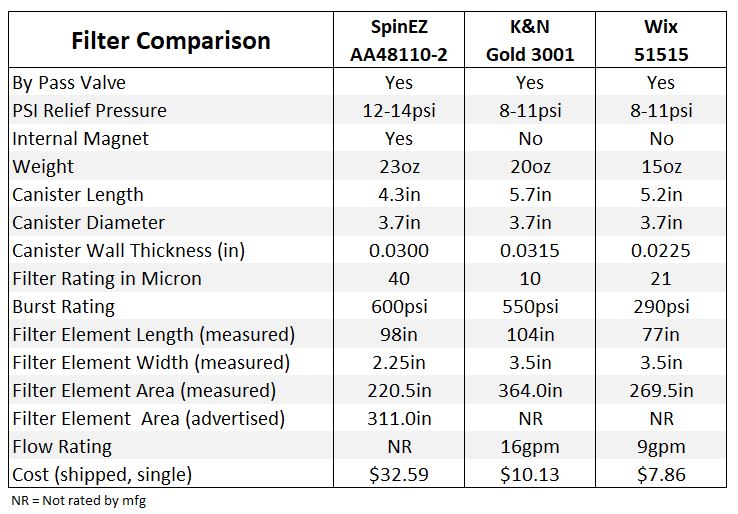

I read through this thread with interest as members compared certified oil filters to auto counterparts, so I decided to cut some auto filters open after my last oil change for the purpose of looking at and measure some of the physical differences to the Tempest SpinEZ AA48110-2 filter I had been using. Please don’t take this other than what it is; some photos of the different filters and as best I could, documented differences from either the manufacturers specs or from what I could measure.

There was one noted difference in the Tempest SpinEZ filter mfg dimensions from what I measured. It could have been because I was measuring a used(soaked) filter. I measured the media by cutting it out of the filter, clamping one end in the vise, pulling it tight and measuring it.

These all seem to be good, well-constructed filters. The biggest difference that I noted was how the bi-pass filter was constructed. In the SpinEZ filter, it is internal to the filter spindle, the Wix had a spring at the filter end (bottom) and the entire media moved to open the bi-pass, and the K&N had a small simple spring bi-pass an the end (bottom). The SpinEZ filter was the only one with a magnet. This is controversial, and some believe that during times where the pressure bi-pass opens (with cold/thick oil), there is a potential to run ferrite debris caught on the magnet back into the engine, unfiltered. Those apposed to the magnet would rather see the debris caught in the filter media where it would stay in the event the bi-pass were to open. The two auto filters had considerably more filter media and both would filter to a much lower micron level. The K&N felt very hefty and more comparable in feel to the SpinEZ. It also could be safety wired like the SpinEZ, for those so inclined.

So there you have it. The SpinEZ filter is around $33 from ACS ($24+S&H), the K&N cost me $10.13 shipped from Amazon and the Wix was $7.86 shipped from Amazon. I’ve read the Wix 51515 is the same as the Napa Gold 1515. I’m SURE you could get all of these filters for less in bulk!

I read through this thread with interest as members compared certified oil filters to auto counterparts, so I decided to cut some auto filters open after my last oil change for the purpose of looking at and measure some of the physical differences to the Tempest SpinEZ AA48110-2 filter I had been using. Please don’t take this other than what it is; some photos of the different filters and as best I could, documented differences from either the manufacturers specs or from what I could measure.

There was one noted difference in the Tempest SpinEZ filter mfg dimensions from what I measured. It could have been because I was measuring a used(soaked) filter. I measured the media by cutting it out of the filter, clamping one end in the vise, pulling it tight and measuring it.

These all seem to be good, well-constructed filters. The biggest difference that I noted was how the bi-pass filter was constructed. In the SpinEZ filter, it is internal to the filter spindle, the Wix had a spring at the filter end (bottom) and the entire media moved to open the bi-pass, and the K&N had a small simple spring bi-pass an the end (bottom). The SpinEZ filter was the only one with a magnet. This is controversial, and some believe that during times where the pressure bi-pass opens (with cold/thick oil), there is a potential to run ferrite debris caught on the magnet back into the engine, unfiltered. Those apposed to the magnet would rather see the debris caught in the filter media where it would stay in the event the bi-pass were to open. The two auto filters had considerably more filter media and both would filter to a much lower micron level. The K&N felt very hefty and more comparable in feel to the SpinEZ. It also could be safety wired like the SpinEZ, for those so inclined.

So there you have it. The SpinEZ filter is around $33 from ACS ($24+S&H), the K&N cost me $10.13 shipped from Amazon and the Wix was $7.86 shipped from Amazon. I’ve read the Wix 51515 is the same as the Napa Gold 1515. I’m SURE you could get all of these filters for less in bulk!

Last edited:

I read through this thread with interest as members compared certified oil filters to auto counterparts, so I decided to cut some auto filters open after my last oil change for the purpose of looking at and measure some of the physical differences to the Tempest EZ-Spin AA48110-2 filter I had been using. Please don’t take this other than what it is; some photos of the different filters and as best I could, documented differences from either the manufacturers specs or from what I could measure.

There was one noted difference in the Tempest EZ-Spin filter mfg dimensions from what I measured. It could have been because I was measuring a used(soaked) filter. I measured the media by cutting it out of the filter, clamping one end in the vise, pulling it tight and measuring it.

These all seem to be good, well-constructed filters. The biggest difference that I noted was how the bi-pass filter was constructed. In the EZ-Spin filter, it is internal to the filter spindle, the Wix had a spring at the filter end (bottom) and the entire media moved to open the bi-pass, and the K&N had a small simple spring bi-pass an the end (bottom). The EZ-Spin filter was the only one with a magnet. This is controversial, and some believe that during times where the pressure bi-pass opens (with cold/thick oil), there is a potential to run ferrite debris caught on the magnet back into the engine, unfiltered. Those apposed to the magnet would rather see the debris caught in the filter media where it would stay in the event the bi-pass were to open. The two auto filters had considerably more filter media and both would filter to a much lower micron level. The K&N felt very hefty and more comparable in feel to the EZ-Spin. It also could be safety wired liek the EZ-Spin, for those so inclined.

So there you have it. The EZ-Spin filter is around $33 from ACS ($24+S&H), the K&N cost me $10.13 shipped from Amazon and the Wix was $7.86 shipped from Amazon. I’ve read the Wix 51515 is the same as the Napa Gold 1515. I’m SURE you could get all of these filters for less in bulk!

Looks like from the pics that the two auto filters have anti-drainback gaskets and the aviation filter doesn't. They help get oil in the bearings faster at startup.'

I have never used an aviation filter, so don't know if this is correct from personal experience though. I do know that the wix and K&N have them, as they come out full of oil.

Larry

Safety wiring oil filters is one of aviation's greatest mysteries to me.

One other, is safety wiring NPT thread plugs.

In either case, if they're appropriately torqued they will never spin off.

There's no provisions for safety wire on the Rotax 912 oil filter.

So why bother?

I can tell you from experience, nothing gets loose faster than an oil filter that has not been safety. I got distracted and forgot to safety wire. by the time I was on crosswind, oil was coming through the floor and vents. By the time I made a kamikaze landing, I had perhaps two QTS left in the sump. I wiped oil in the cockpit for the next few months after each flight.

Here are the images of my oil filter:

https://photos.google.com/album/AF1.../AF1QipORguQ0kPMZ-TwiKT1_408MbzZYJauJ54cwZWwt

https://photos.google.com/album/AF1.../AF1QipOTU69592UvQExLaTPprNzhtcNoeI8D3ftp4yt9

https://photos.google.com/album/AF1.../AF1QipPFJreXYfdjqR3cTnXgTh6oOf9th3v1WChpug8E

https://photos.google.com/album/AF1.../AF1QipMcstk4XmyYYjk93RaUxlXYItQeCc4b5QFPZNPn

This oil filter makes it easy to see and clean the screen. It is a reusable filter sold here https://www.aircraftspruce.com/catalog/eppages/challengerLifetime.php. The black glob you see is the magnet collecting my new cylinder break-in wear. I used to change my oil every 25 hrs and filter every 50 hrs. Now, I do both at every 25 hrs. $0 cost at each oil change.

https://photos.google.com/album/AF1.../AF1QipORguQ0kPMZ-TwiKT1_408MbzZYJauJ54cwZWwt

https://photos.google.com/album/AF1.../AF1QipOTU69592UvQExLaTPprNzhtcNoeI8D3ftp4yt9

https://photos.google.com/album/AF1.../AF1QipPFJreXYfdjqR3cTnXgTh6oOf9th3v1WChpug8E

https://photos.google.com/album/AF1.../AF1QipMcstk4XmyYYjk93RaUxlXYItQeCc4b5QFPZNPn

This oil filter makes it easy to see and clean the screen. It is a reusable filter sold here https://www.aircraftspruce.com/catalog/eppages/challengerLifetime.php. The black glob you see is the magnet collecting my new cylinder break-in wear. I used to change my oil every 25 hrs and filter every 50 hrs. Now, I do both at every 25 hrs. $0 cost at each oil change.

KatanaPilot

Well Known Member

Looks like from the pics that the two auto filters have anti-drainback gaskets and the aviation filter doesn't. They help get oil in the bearings faster at startup.'

I have never used an aviation filter, so don't know if this is correct from personal experience though. I do know that the wix and K&N have them, as they come out full of oil.

Larry

I agree in part. Two situations where I disagree.

1. If the engine has an 90 degree oil filter adapter - the oil will drain back to the engine in a hour or two, even if there is an anti-drainback gasket. My assumption is the oil seeps through the filter media and drains back through the inner core return. I've verified this during oil changes where I've waited a while before removing the oil filter. Not a drop came out.

2. Even if the oil filter is mounted horizontally, approximately half of the oil (the amount above the inner core return tube) will also drain out given enough time.

I'm not a lubrication engineer, but I believe that one way to have no drainback (and therefore much quicker oil pressure rise) would be to firewall mount a remote oil filter vertically, with the filter hanging below the remote mount. It's what I'm doing on my RV-10 using a Challenger/K&P permanent oil filter.

I'm not a lubrication engineer, but I believe that one way to have no drainback (and therefore much quicker oil pressure rise) would be to firewall mount a remote oil filter vertically, with the filter hanging below the remote mount. It's what I'm doing on my RV-10 using a Challenger/K&P permanent oil filter.

I have mine firewall mounted vertically. Only issue is being messy when removing. The hoses drain to the filter therefore once you start spinning if off, oil comes running out and down the sides. Tried using ziplock bag over it but the oil running inside bag makes it slippery to spin off. What works best is to poke a hole at the bottom and top on the side of the filter and let the oil in the filter, and that from the hose, drain out. The trick is after using a punch and hammer to poke holes in the canister is to use a hinge pin to poke a hole through the filter element inside the canister (lower hole only) to get oil from both sides of the filter to drain. I use one of the form-a-funnels to direct the oil running out of the holes into a bucket.

steve murray

Well Known Member

I read through this thread with interest as members compared certified oil filters to auto counterparts, so I decided to cut some auto filters open after my last oil change for the purpose of looking at and measure some of the physical differences

Thanks for your efforts & sharing the data, this is very helpful for me.

I can tell you from experience, nothing gets loose faster than an oil filter that has not been safety.

General industry experience based on 100's of millions of automobiles are counter to your experience. Your experience points to an installation procedure issue. A properly installed oil filter should not come loose, even without safety wire.

Larry

Last edited:

Pilot135pd

Well Known Member

Personally I can't imagine why anyone would go thru all the trouble to convert an auto filter when the total saving is probably less than $10

Champion $28.50 plus shipping

Tempest $23.50 plus shipping

WIX 51515 $8.09 at my local O’Reilly or Napa or Advance Auto or ......

My engine has been using the WIX 51515 for over 450 hours and no safety wire. It also doesn’t use a nipple so it changes just as easy as any aviation filter.

Last edited:

I found this thread to be quite interesting. From a informational and human interest point. While I do not care to do the Science, I enjoy reading about the Science. I then apply that Science to benefit me as I deem fit.

The part of the thread where safety clashes with cost (2018) , always a good debate to have, fails to include a valuable part.

We have to remember that many in this group are Scientists doing research work. They do it to discover, to share. Saving a dollar is always fun, but I don?t think the driving force.

E mags would be another example. A lot of damaged cylinders, soiled underwear, and maybe worse working that science. And yet it continues.

To all of you....Experimentalogist...I salute you.

R

The part of the thread where safety clashes with cost (2018) , always a good debate to have, fails to include a valuable part.

We have to remember that many in this group are Scientists doing research work. They do it to discover, to share. Saving a dollar is always fun, but I don?t think the driving force.

E mags would be another example. A lot of damaged cylinders, soiled underwear, and maybe worse working that science. And yet it continues.

To all of you....Experimentalogist...I salute you.

R

Pilot135pd

Well Known Member

It's interesting to note that Robinson Helicopter does not require the safety wiring of the Lycoming engine oil filter per their Service Letter shown below:

https://robinsonheli.com/wp-content/uploads/2015/12/r44_sl45.pdf

SUBJECT: Deleted Safety Wire"BACKGROUND: Safety wire and safety wire provisions have been deleted from various installations and parts. Deleting safety wire reduces maintenance cost and decreases the potential for safety wire-related FOD. This letter provides guidance for installing parts with or without safety wire provisions."

...

"? Lycoming engines: Oil filters and D723-1 adapter assemblies with or without safety wire provisions do not require safety wire. Installation instructions are on the oil filter."

I used to own an R-22 Mariner and if that vibration doesn't loosen an oil filter then my smooth RV-8 never will

K&P Engineering

If you call K&P engineering and tell them that you want a filter for an experimental aircraft, they will sell you one. If you want to order one online, then go to http://usaoilfilters.com and buy these components:

Housing: C4, if you want the 1" nut and safety wire holes, C3 if you just want a standard housing.

Filter: FE-15 (3/4-16 female thread)

Spring: RS1 (this is the retaining spring that goes in the housing, and then the filter)

Quad Ring: QR2 (this is the reusable, replaceable o-ring)

It's not inexpensive, but flows very well and maintains consistent filtering throughout the entire oil change cycle. I have several of these, on each of my vehicle and aircraft engines. Very high quality.

If you call K&P engineering and tell them that you want a filter for an experimental aircraft, they will sell you one. If you want to order one online, then go to http://usaoilfilters.com and buy these components:

Housing: C4, if you want the 1" nut and safety wire holes, C3 if you just want a standard housing.

Filter: FE-15 (3/4-16 female thread)

Spring: RS1 (this is the retaining spring that goes in the housing, and then the filter)

Quad Ring: QR2 (this is the reusable, replaceable o-ring)

It's not inexpensive, but flows very well and maintains consistent filtering throughout the entire oil change cycle. I have several of these, on each of my vehicle and aircraft engines. Very high quality.

Or just purchase this.... https://usaoilfilters.com/product/s15/ and save $21.00 and it includes the cup wrench.

erich weaver

Well Known Member

Another thread on the permanent oil filter is here:

http://www.vansairforce.com/community/showthread.php?t=171973

If you use the Tempest 48108-2 filters you need the C4 filter housing and the S15 filter

http://www.vansairforce.com/community/showthread.php?t=171973

If you use the Tempest 48108-2 filters you need the C4 filter housing and the S15 filter

Last edited:

Or just purchase this.... https://usaoilfilters.com/product/s15/ and save $21.00 and it includes the cup wrench.

True, but doesn't include the really cool 1" nut and safety wire holes in a top flange...

gmcjetpilot

Well Known Member

Engines "oil filter" in the day came with a metal screen...

rocketbob

Well Known Member

Engines "oil filter" in the day came with a metal screen...

Screens are perfectly fine. In fact micron rating is the same as certified paper filters, 40 micron.

I recently got interesting in oil filters. Ran across this thread while searching something else. I'll bet that happens a lot. A few random notes....

Micron ratings come in two flavors, absolute and nominal. Neither is useful for decision making without also stating the beta value, effectively the percentage of a particular particle size captured by the filter.

I can claim my T-shirt will stop a 20 micron particle, and it probably will. However, the beta may be 2, i.e. 50% efficient, i.e. half the 20 micron particles pass through. Micron stated without a beta is just talk.

Most filter manufacturers test for a dual beta, i.e. beta at two particle sizes. If it's not published, ask. For example, the NAPA 1515 is a Wix 51515. The nominal micron rating is 21, but note the beta values, listed as 2/20=6/20. It means beta is "2" for a 6 micron particle and "20" for a 20 micron particle. A 2 beta means it is stopping 50% of the stated particle size, while a 20 beta is 95%.

Now look at the listing for bypass valve setting, 8 to 11 psi, about 25% lower than the bypass setting specified by Lycoming and Continental. It means dirty oil is bypassing the filter element more often than it does with a xx108 or xx109 internal bypass aviation filter.

Which raises another point. Screwing a NAPA 1515 onto a Lycoming adapter intended for use with a xx110 or xx111 filter effectively disables the adapter's bypass. The 1515's bypass opens at a lower pressure.

A lower bypass opening pressure has nothing to do with burst pressure. The bypass relieves pressure across the filter element, but does not change can pressure.

Thank you Brian, but there are two misconceptions here. First, the AA48110-2 has no internal bypass, nor does the larger 48111. Same for the Champion versions. Pressure does not move the element. The bypass valve is in the engine's filter adapter. The leaf spring merely locates the element and holds it against the base plate. Same is true of the big coil spring found in the same locations in other filters.

The Wix bypass valve is the small top hat module sandwiched between the base plate and the filter element. It is self-contained; bypass flow is in through the holes you see around the perimeter, exiting into the center bore. Wix filters with no bypass substitute a module with the same external shape, but having no holes, internal diaphragm seal, or spring. It's just an inert filler.

The K&N pictured here does indeed have a poppet valve bypass, very similar to the bypass currently installed in the 108 and 109 aviation filters. I have not looked up its pressure rating.

Micron ratings come in two flavors, absolute and nominal. Neither is useful for decision making without also stating the beta value, effectively the percentage of a particular particle size captured by the filter.

I can claim my T-shirt will stop a 20 micron particle, and it probably will. However, the beta may be 2, i.e. 50% efficient, i.e. half the 20 micron particles pass through. Micron stated without a beta is just talk.

Most filter manufacturers test for a dual beta, i.e. beta at two particle sizes. If it's not published, ask. For example, the NAPA 1515 is a Wix 51515. The nominal micron rating is 21, but note the beta values, listed as 2/20=6/20. It means beta is "2" for a 6 micron particle and "20" for a 20 micron particle. A 2 beta means it is stopping 50% of the stated particle size, while a 20 beta is 95%.

Now look at the listing for bypass valve setting, 8 to 11 psi, about 25% lower than the bypass setting specified by Lycoming and Continental. It means dirty oil is bypassing the filter element more often than it does with a xx108 or xx109 internal bypass aviation filter.

Which raises another point. Screwing a NAPA 1515 onto a Lycoming adapter intended for use with a xx110 or xx111 filter effectively disables the adapter's bypass. The 1515's bypass opens at a lower pressure.

A lower bypass opening pressure has nothing to do with burst pressure. The bypass relieves pressure across the filter element, but does not change can pressure.

...I decided to cut some auto filters open after my last oil change for the purpose of looking at and measure some of the physical differences to the Tempest SpinEZ AA48110-2 filter I had been using.

These all seem to be good, well-constructed filters. The biggest difference that I noted was how the bi-pass filter was constructed. In the SpinEZ filter, it is internal to the filter spindle, the Wix had a spring at the filter end (bottom) and the entire media moved to open the bi-pass, and the K&N had a small simple spring bi-pass an the end (bottom).

Thank you Brian, but there are two misconceptions here. First, the AA48110-2 has no internal bypass, nor does the larger 48111. Same for the Champion versions. Pressure does not move the element. The bypass valve is in the engine's filter adapter. The leaf spring merely locates the element and holds it against the base plate. Same is true of the big coil spring found in the same locations in other filters.

The Wix bypass valve is the small top hat module sandwiched between the base plate and the filter element. It is self-contained; bypass flow is in through the holes you see around the perimeter, exiting into the center bore. Wix filters with no bypass substitute a module with the same external shape, but having no holes, internal diaphragm seal, or spring. It's just an inert filler.

The K&N pictured here does indeed have a poppet valve bypass, very similar to the bypass currently installed in the 108 and 109 aviation filters. I have not looked up its pressure rating.

Attachments

Last edited:

Toobuilder

Well Known Member

There is often a lot of discussion concerning the "clogged filter bypass" scenario... How often does this actually occur, and even then, what is the actual realized downside? A reduction in TBO by 5 hours? Not that long ago, these engines had nothing but a course screen to keep the chunks at bay. Even the cheapest automotive filter is more effective at cleaning oil than the engine was designed for, so is it really an issue if you get a bypass every now and then?

The fact is, the "best" full flow filter is a compromise between filtration and flow. If we want enough flow to keep the bearings alive, it HAS to pass trash big enough to wedge in a bearing clearance and remove metal.

A paper filter is better than a perforated screen, but "clean" oil is relative.

A little research on "bypass oil filtration" is worth the time. These filters are so fine they will even strip the additives out of the oil (in addition to ALL the trash), but they dont flow enough to keep the bearings alive at full flow. Cant have it both ways.

The fact is, the "best" full flow filter is a compromise between filtration and flow. If we want enough flow to keep the bearings alive, it HAS to pass trash big enough to wedge in a bearing clearance and remove metal.

A paper filter is better than a perforated screen, but "clean" oil is relative.

A little research on "bypass oil filtration" is worth the time. These filters are so fine they will even strip the additives out of the oil (in addition to ALL the trash), but they dont flow enough to keep the bearings alive at full flow. Cant have it both ways.

Mike S

Senior Curmudgeon

A little research on "bypass oil filtration" is worth the time. These filters are so fine they will even strip the additives out of the oil (in addition to ALL the trash), but they dont flow enough to keep the bearings alive at full flow. Cant have it both ways.

Bypass filters do not filter the entire flow------that is what a full flow filter does.

Bypass filters take a portion of the flow and filter it, leaving most of the pump output to lube the engine.

Toobuilder

Well Known Member

Yes, exactly my point. They filter very effectively but just "ooze" while doing it. Over time, the crankcase is left with very clean oil, but no, the bearings are not protected if it starts making metal.

Even the best "full flow" filters pass debris large enough to score bearings. Clamp down the micron count (like with a bypass filter) and it wont flow enough to keep the bearings lubricated. Sure the oil will be clean, but not enough volume to keep the bearings afloat.

Like I said, "clean oil" is relative.

Even the best "full flow" filters pass debris large enough to score bearings. Clamp down the micron count (like with a bypass filter) and it wont flow enough to keep the bearings lubricated. Sure the oil will be clean, but not enough volume to keep the bearings afloat.

Like I said, "clean oil" is relative.

Mike S

Senior Curmudgeon

Clamp down the micron count (like with a bypass filter) and it wont flow enough to keep the bearings lubricated.

Again, the bypass filter is only cleaning a small quantity of the oil being supplied by the pump. This clean oil is returned directly to the oil pan. It is not used as the pressure feed to lube the bearings etc.

The vast majority of the oil pump output is still being used to lube the engine.

Sure the oil will be clean, but not enough volume to keep the bearings afloat.

That is why we now have full flow oil filters-----they do flow enough to lube the engine.

Last edited:

Even the best "full flow" filters pass debris large enough to score bearings.

What size would that be Mike?

Clamp down the micron count (like with a bypass filter) and it wont flow enough to keep the bearings lubricated.

The Wix 51515 I used as an example is rated at 7 to 9 gallons per minute, which on its face is enough to satisfy the Lycomings we use. However, I'll need to get my hands on the appropriate ISO standard to know the viscosity used for the rating. Bet it ain't 50w

Bottom line regarding bypass deltaP is simple. It should open just below the pressure which would crush the element. Otherwise, it should never open.

Last edited:

hgerhardt

Well Known Member

....... However, I'll need to get my hands on the appropriate ISO standard to know the viscosity used for the rating. Bet it ain't 50w.....

Exactly. No other engines in general use nowadays use that thick of an oil...except maybe Harleys.

Along that same line of thinking, it makes sense to maximize the filter media area to allow a higher flowrate, and probably less bypassing when oil is cold. All of the filters we typically use on Lycomings come in short and long versions. I've been using the long ones almost exclusively on my RV as there's plenty of room between the engine and firewall. But I have one of those odd Dual-Mag engines which offset the filter to where the RH mag would normally go. If you have enough clearance for the bigger filter, why not use one? They cost the same. (48110 vs 48111)

BillL

Well Known Member

There is often a lot of discussion concerning the "clogged filter bypass" scenario... How often does this actually occur, and even then, what is the actual realized downside?

The by-pass addresses several scenarios. Cold oil is one, where the engine rpm goes high enough with low temps to yield a high delta-p across the filter. It may only happen a few times in winter under limits of oil and temperatures. If the event collapses the filter media then the aircraft could take off and result in engine failure.

The other is if debris clogs the filter media inflight (possibly engine making metal) it becomes the lessor of evils as the engine needs oil. As we know a few extra minutes or seconds of having engine power could be an airport landing vs a smoking hole.

The filters are industry standards to eliminate failure modes known only to the archives of NTSB and engine manufacturers.

There are reasons for all the capabilities built into the standard filters and supported by the design validation standards.

For example, we could use a filter with lower burst, if we are careful about preheat, and not taking off until a certain temp is reached.

I went to the dark side!

Since it's hard to get a filter I decided to install the WIX 51515. I used the nipple from my used Champion filter. I screwed the end of the nipple that was in the old filter into the oil filter adaptor. I used red loctite. My big question is how tight do you screw on the new filter? I saw someone say 3/4 turn after contact like a car. Does that work?

Since it's hard to get a filter I decided to install the WIX 51515. I used the nipple from my used Champion filter. I screwed the end of the nipple that was in the old filter into the oil filter adaptor. I used red loctite. My big question is how tight do you screw on the new filter? I saw someone say 3/4 turn after contact like a car. Does that work?

Mike S

Senior Curmudgeon

I saw someone say 3/4 turn after contact like a car. Does that work?

That is how I do it.

Never had an issue with that method.

That is how I do it.

Never had an issue with that method.

That's because it equates to the torque printed on a Champion Aerospace filter.

BillL

Well Known Member

I saw someone say 3/4 turn after contact like a car. Does that work?

That is how I do it.

That's because it equates to the torque printed on a Champion Aerospace filter.

I asked an oil filter test engineer and he said (and I looked at the test standard) that the test protocol requires the pulsating oil leakage test to be performed at 1/4, 1/2, and 3/4 turns. He said they all pass the test.

So 3/4 is good, golden in fact.

Just let your oil get warmed up before full rpm in cold weather. You probably do anyway.