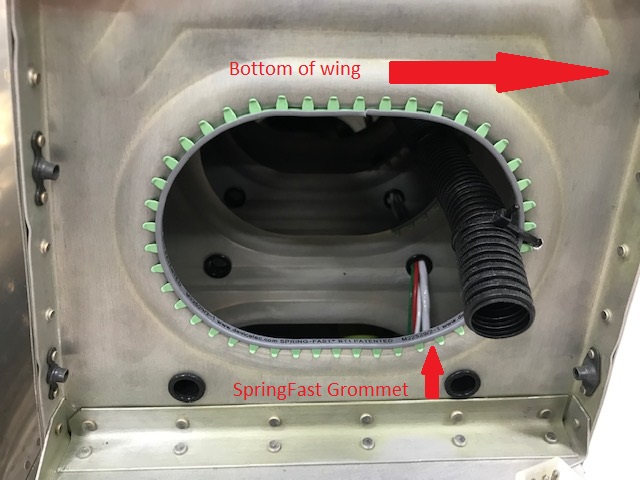

wing conduit in a mounted wing of a flying aircraft

Running wing conduit in a mounted wing of a flying aircraft?

The second avionics update for my store bought -6 had me install an OAT probe close to the aileron bellcrank access on the right wing.

There are several ways to do this, the one used here was "cheap" and required awkward gymnastics... why are my arm and fist joints where they are and not where required for the task I ask

In a nutshell:

- had some leftover conduit as used when I built the -4 (just about 30 years ago...), only 4mm i.d. but plenty for the wire used

- the search engine is your friend and Mouser has exactly what I was looking for: Harness Clip, Mouser P/N 523-ALBCBS3045909. Right size and enough clamping pressure

- gain access to the ribs, e.g. remove the right seat and panels below, remove the aileron boots, remove the 2 bolts holding the right aileron pushrod and push it to the other side, and open the right aileron bellcrank access panel

- clip the clips on the ribs: for the hard to reach middle ribs, precisely measure the between ribs distance, then drill/dremel the cavities for the clips on a 2x1". Attach the conduit held to the clips by plastic ties onto that piece of wood, secure with some thin masking tape. Insert that contraption from the access panel side, adjust and slightly hammer the 2x1" down and remove it. For the rest of the clips, try retracting all muscles and bending the bones of your arm to reach the clips on the ribs from inside the fuse and the access panel...

- reinstall everything and check the clearance between the aileron pushrod and the clips