RVbySDI

Well Known Member

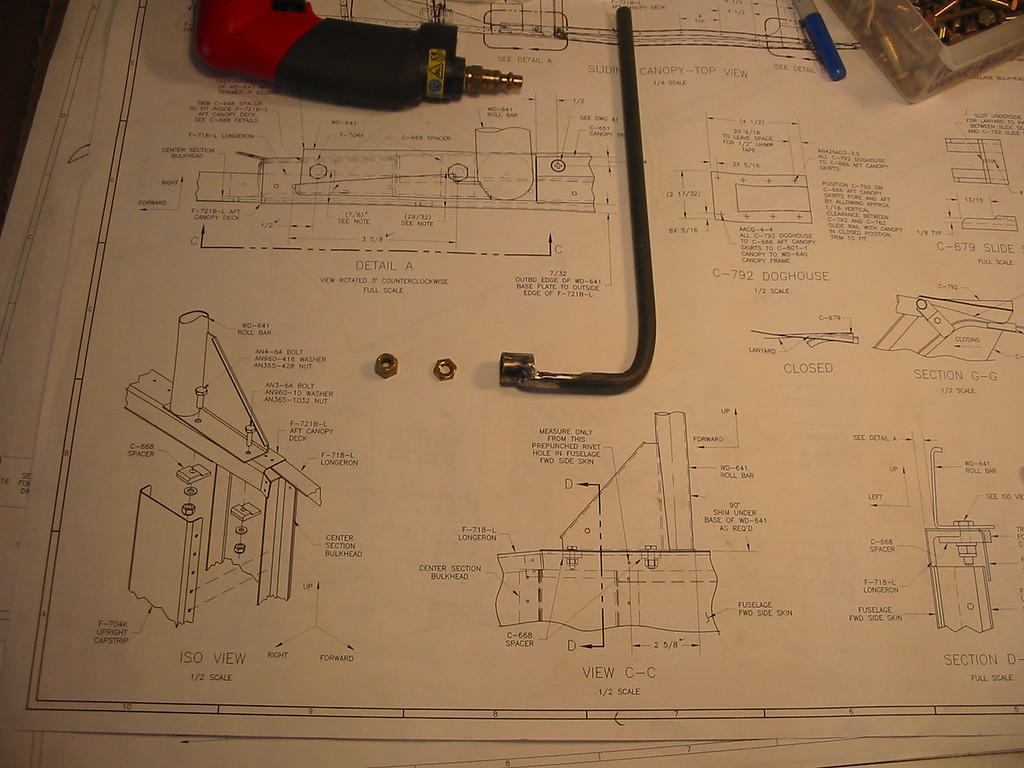

I need to mount a RAM mount ball to the triangle gusset of the windscreen frame. Here is a picture of where I am wishing to secure the RAM mount:

My question: Can anyone suggest an adhesive that will allow me to mount the RAM in this location that will withstand the weight of an iPad?

I have PLIOBOND that I can use but does anyone know if this will be strong enough for this application?

Any other thoughts on what will bond the aluminum RAM mount to the powder coated steal windscreen frame?

My question: Can anyone suggest an adhesive that will allow me to mount the RAM in this location that will withstand the weight of an iPad?

I have PLIOBOND that I can use but does anyone know if this will be strong enough for this application?

Any other thoughts on what will bond the aluminum RAM mount to the powder coated steal windscreen frame?