Hello everyone, as some of you may know I had a little incident while getting very close to done on my project that has delayed it a few months. Some time has passed and I'm ready to tell the story in hopes that no one else makes the same mistake.

So there I was 6 days away from final inspection and I was doing my third engine start to test a new idle setting. I had also just finished setting the last 8 rivets of the entire project while finishing the spinner installation. I have been a pilot since 2005 and have always prided myself on doing a thorough preflight and following checklists. However I made a mistake on when a preflight should be done. I was not planning on flying the plane after this engine start so I did not do a preflight. That mistake ended up costing a lot of money.

Turns out I had left my bucking bar laying on top of my air filter. After starting the engine you can imagine that it found its way into the spinning propeller. I saw something launch into the air (thinking it was a piece of my newly installed spinner) and it landed on my left wing. I shut her down to figure out what was going on. As the prop was coming to a stop I could see a light metallic spot on the prop where black paint should be. It was at this point I knew it was bad.

I got out and found a bucking bar laying behind my wing on the ground. After saying every bad word I could think of and probably inventing some new ones I pushed it back in the hangar and left to go home as I knew nothing good would come of me staying there.

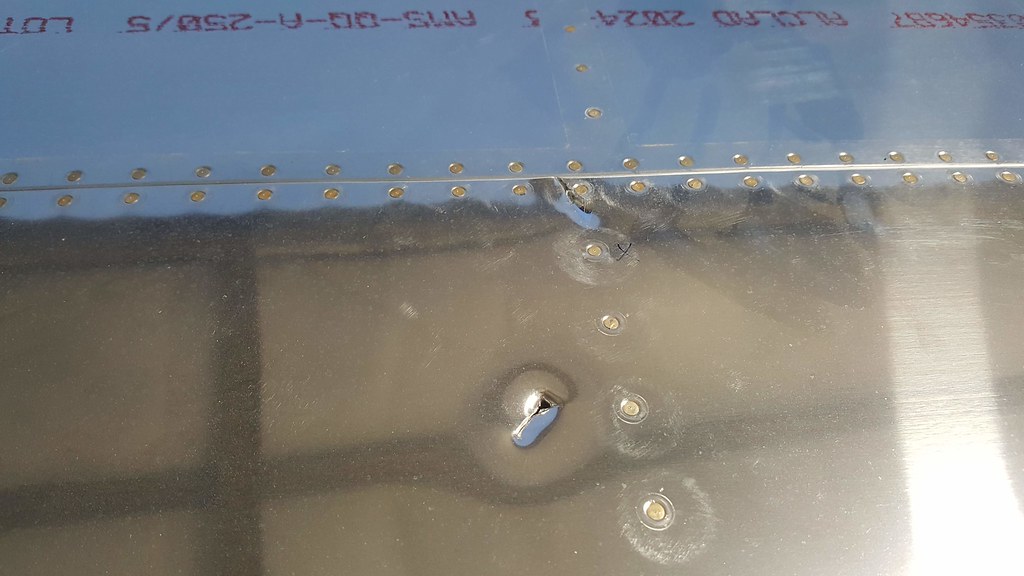

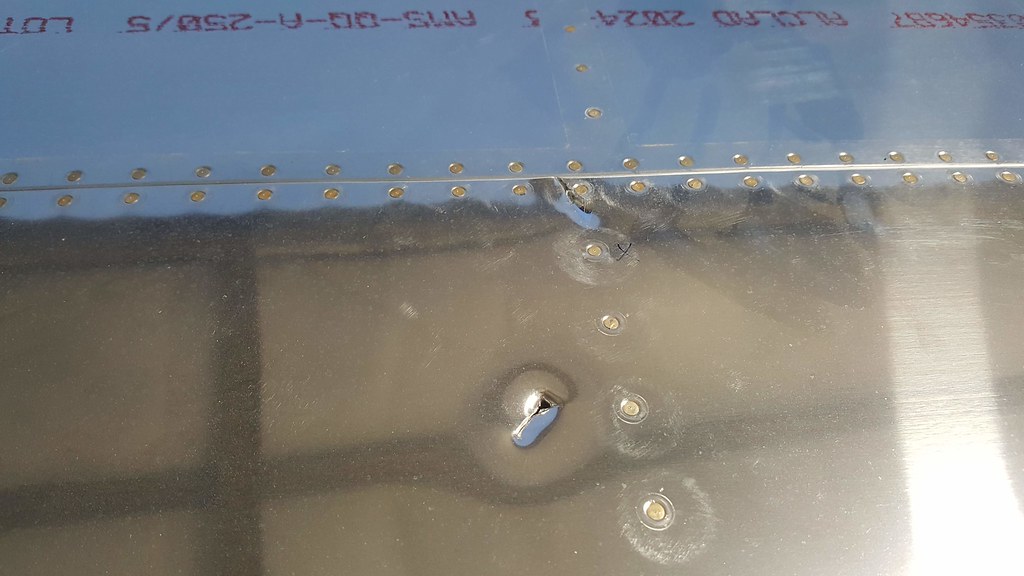

I later went back and decided I needed to take some pictures and see if insurance would cover this. I also looked up the prop strike service bulletin from Lycoming only to confirm my worst fears. Here are some pics of the damage.

20200922_191644 by Jereme Carne, on Flickr

20200922_191644 by Jereme Carne, on Flickr

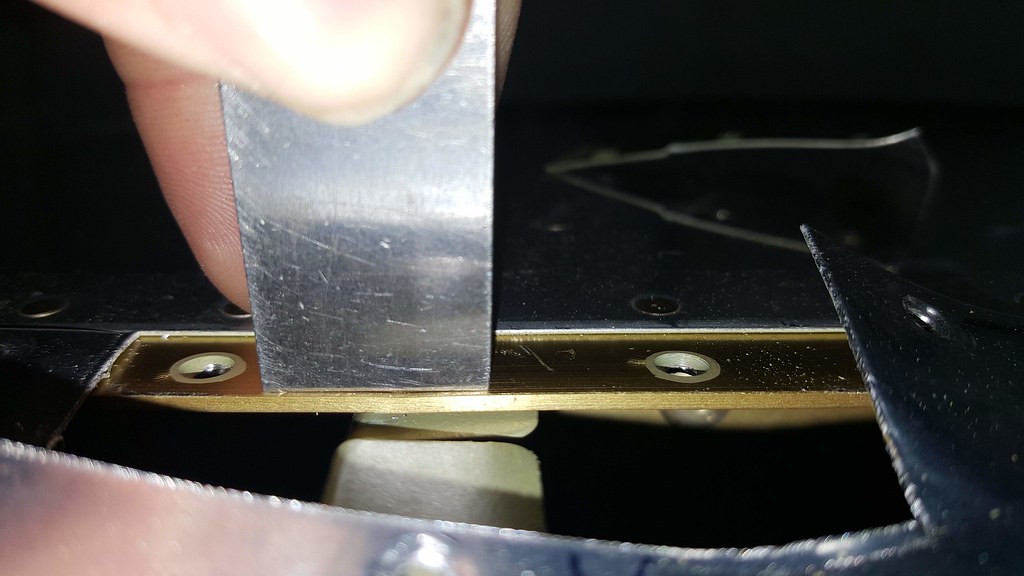

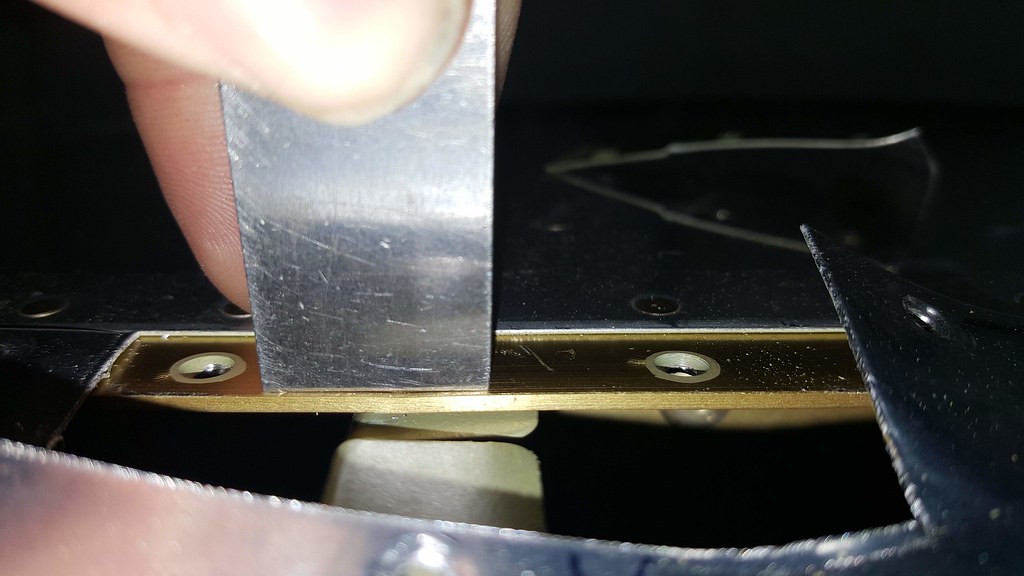

As you can see it punctured the left top outboard wing skin and left a big question mark on what it did to the spar. I decided to drill some rivets out (knowing the skin would have to be replaced) and remove some of the skin to get access to the spar. Here is a picture of what it did to the spar. There was a slight bend in it but not much at all. Van's support looked at it as well as engineering and it was all good to go, no worries at all. Thank goodness, that was a lucky break.

20200923_171353 by Jereme Carne, on Flickr

20200923_171353 by Jereme Carne, on Flickr

Here is the damage on the prop. I thought for sure that blade was going to have to be replaced but in the end it could be blended and repainted. Since I didn't lose any RPM (in fact it was still building up to 1000) the prop didn't need overhauled either. The first shop I talked to wanted to do an overhaul and replace the blade but wasn't really working with me on how to get it to them so I took my business else where. I happened to find a YouTube video touring the facilities at Texas Aircraft Propellers and Accessories and knew this is where I wanted it to go. They are a Hartzell recommended service center as well which was nice. They shipped me a box at no charge other than shipping. Great service, HIGHLY recommend them.

20200922_191602 by Jereme Carne, on Flickr

20200922_191602 by Jereme Carne, on Flickr

The prop was fixed as mentioned and they didn't even have to take the hub apart which I'm excited about; means I shouldn't have to replace any of my spinner bulkheads.

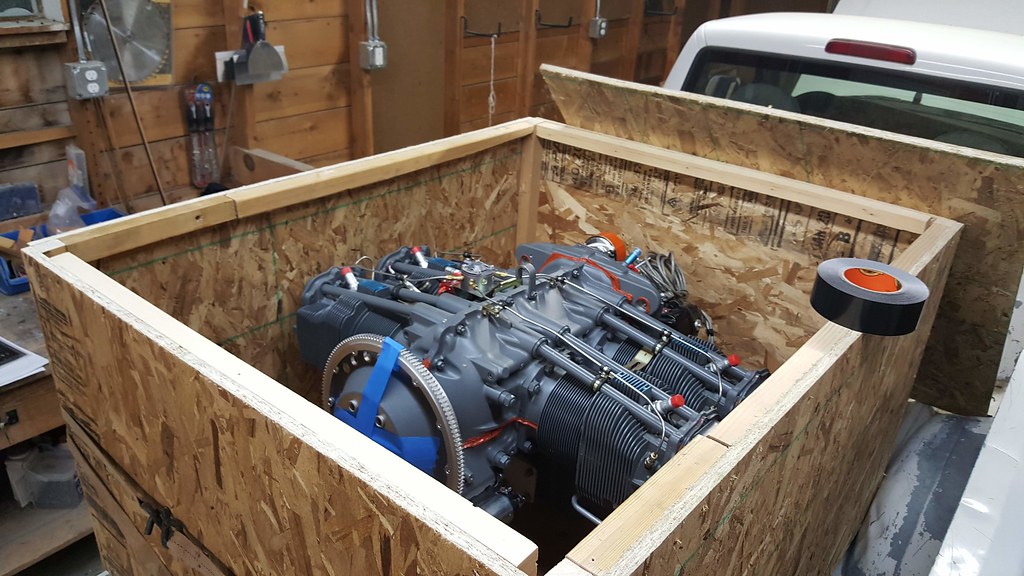

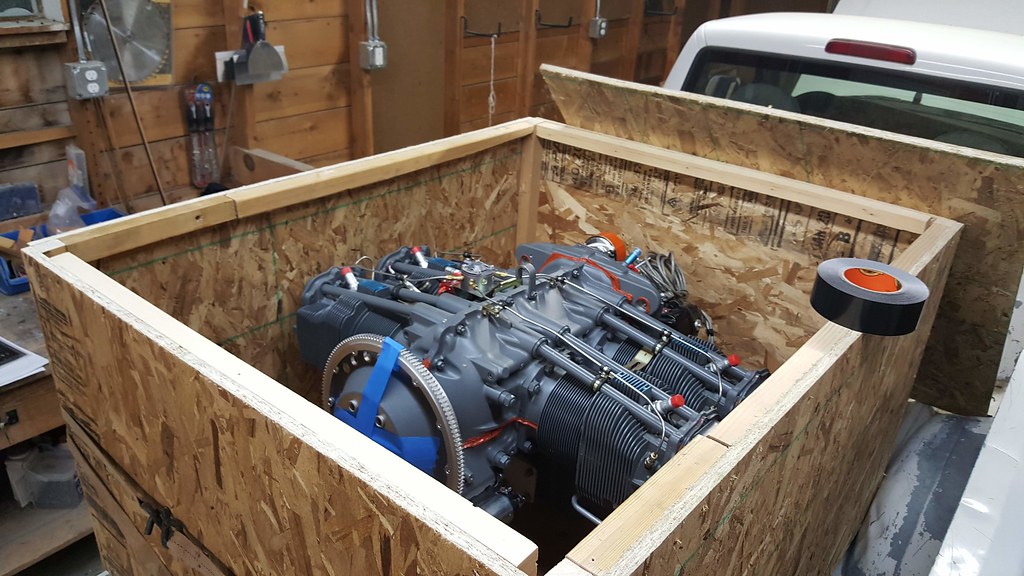

Now for the part I knew was going to be pricey, the engine... According to Lycoming if the prop needs repaired it needs a teardown inspection. I knew this was going to be a completely unnecessary step but rules will be rules. I believe Lycoming even has an AD on prop strikes so the DAR could have refused me certification. I contacted our trusty guys up at Aerosport Power and they made arrangements for pickup. They have been great to work with so far. Here she is all ready to go. It's also worth mentioning that I contacted Lycoming directly and they recommended a teardown inspection.

20201001_220319 by Jereme Carne, on Flickr

20201001_220319 by Jereme Carne, on Flickr

The inspection report came back and as I suspected nothing was found. However, Lycoming specifies some things be mandatory replacement like roller lifters (at about 3k worth for anyone interested), bearings, magnetos, and a few other things.

The engine is off to paint and assembly and eventually to test running and I should have it back sometime in early to mid December.

Fixes are under way, wing skin has been replaced and aileron and flap rerigged. Just waiting to put the engine back on at this point.

20201011_180839 by Jereme Carne, on Flickr

20201011_180839 by Jereme Carne, on Flickr

So why do I bring this up? What is the takeaway? Well there are a few of them.

1. I mistakenly thought that a preflight wasn't needed since I wasn't flying. In hindsight anytime you turn a mag on you are a pilot and no longer a builder. I will always do a full preflight anytime a mag goes hot.

2. I am never going to set anything on top of my engine again.

3. Get you some builders insurance. Luckily I have had builders insurance for a few years now and boy I'm glad I did because this was many thousands of dollars to remedy. The insurance adjuster even mentioned to me that I am by no means the first person that has ever done this. Highly recommend anyone without builders insurance get some because it REALLY saved my bacon. I was a in a pretty dark place until I found out it was covered. (thought I was going to have to sell the project and cut losses)

4. This could have been much worse if it hit the canopy, fuel tank, or someone including myself. 2 lbs of pure tungsten hitting oneself would not have been fun.

Anyways, safe building out there everyone and I hope this helps someone avoid the same mistake! P.S. Sorry for contributing to raising our rates... I'm sure I'll make it up with my increased premiums. haha

So there I was 6 days away from final inspection and I was doing my third engine start to test a new idle setting. I had also just finished setting the last 8 rivets of the entire project while finishing the spinner installation. I have been a pilot since 2005 and have always prided myself on doing a thorough preflight and following checklists. However I made a mistake on when a preflight should be done. I was not planning on flying the plane after this engine start so I did not do a preflight. That mistake ended up costing a lot of money.

Turns out I had left my bucking bar laying on top of my air filter. After starting the engine you can imagine that it found its way into the spinning propeller. I saw something launch into the air (thinking it was a piece of my newly installed spinner) and it landed on my left wing. I shut her down to figure out what was going on. As the prop was coming to a stop I could see a light metallic spot on the prop where black paint should be. It was at this point I knew it was bad.

I got out and found a bucking bar laying behind my wing on the ground. After saying every bad word I could think of and probably inventing some new ones I pushed it back in the hangar and left to go home as I knew nothing good would come of me staying there.

I later went back and decided I needed to take some pictures and see if insurance would cover this. I also looked up the prop strike service bulletin from Lycoming only to confirm my worst fears. Here are some pics of the damage.

20200922_191644 by Jereme Carne, on Flickr

20200922_191644 by Jereme Carne, on FlickrAs you can see it punctured the left top outboard wing skin and left a big question mark on what it did to the spar. I decided to drill some rivets out (knowing the skin would have to be replaced) and remove some of the skin to get access to the spar. Here is a picture of what it did to the spar. There was a slight bend in it but not much at all. Van's support looked at it as well as engineering and it was all good to go, no worries at all. Thank goodness, that was a lucky break.

20200923_171353 by Jereme Carne, on Flickr

20200923_171353 by Jereme Carne, on FlickrHere is the damage on the prop. I thought for sure that blade was going to have to be replaced but in the end it could be blended and repainted. Since I didn't lose any RPM (in fact it was still building up to 1000) the prop didn't need overhauled either. The first shop I talked to wanted to do an overhaul and replace the blade but wasn't really working with me on how to get it to them so I took my business else where. I happened to find a YouTube video touring the facilities at Texas Aircraft Propellers and Accessories and knew this is where I wanted it to go. They are a Hartzell recommended service center as well which was nice. They shipped me a box at no charge other than shipping. Great service, HIGHLY recommend them.

20200922_191602 by Jereme Carne, on Flickr

20200922_191602 by Jereme Carne, on FlickrThe prop was fixed as mentioned and they didn't even have to take the hub apart which I'm excited about; means I shouldn't have to replace any of my spinner bulkheads.

Now for the part I knew was going to be pricey, the engine... According to Lycoming if the prop needs repaired it needs a teardown inspection. I knew this was going to be a completely unnecessary step but rules will be rules. I believe Lycoming even has an AD on prop strikes so the DAR could have refused me certification. I contacted our trusty guys up at Aerosport Power and they made arrangements for pickup. They have been great to work with so far. Here she is all ready to go. It's also worth mentioning that I contacted Lycoming directly and they recommended a teardown inspection.

20201001_220319 by Jereme Carne, on Flickr

20201001_220319 by Jereme Carne, on FlickrThe inspection report came back and as I suspected nothing was found. However, Lycoming specifies some things be mandatory replacement like roller lifters (at about 3k worth for anyone interested), bearings, magnetos, and a few other things.

The engine is off to paint and assembly and eventually to test running and I should have it back sometime in early to mid December.

Fixes are under way, wing skin has been replaced and aileron and flap rerigged. Just waiting to put the engine back on at this point.

20201011_180839 by Jereme Carne, on Flickr

20201011_180839 by Jereme Carne, on FlickrSo why do I bring this up? What is the takeaway? Well there are a few of them.

1. I mistakenly thought that a preflight wasn't needed since I wasn't flying. In hindsight anytime you turn a mag on you are a pilot and no longer a builder. I will always do a full preflight anytime a mag goes hot.

2. I am never going to set anything on top of my engine again.

3. Get you some builders insurance. Luckily I have had builders insurance for a few years now and boy I'm glad I did because this was many thousands of dollars to remedy. The insurance adjuster even mentioned to me that I am by no means the first person that has ever done this. Highly recommend anyone without builders insurance get some because it REALLY saved my bacon. I was a in a pretty dark place until I found out it was covered. (thought I was going to have to sell the project and cut losses)

4. This could have been much worse if it hit the canopy, fuel tank, or someone including myself. 2 lbs of pure tungsten hitting oneself would not have been fun.

Anyways, safe building out there everyone and I hope this helps someone avoid the same mistake! P.S. Sorry for contributing to raising our rates... I'm sure I'll make it up with my increased premiums. haha