PilotjohnS

Well Known Member

Canopy, Part 2 - The Big Cut

Today was a warm day, perfect for canopy work.

This weekend was all about cutting the canopy down to size. The on-line experts suggested to use the Dremel Max Saw. This worked out very well. However, they recommended the SM500 plastic blade, I found this to be a really coarse cut. I chose to use the SM510 metal blade. This blade is just like the cut off wheel Van's supplies in the kit, but for the Max Saw. With this blade, if the cuts are made carefully, there is very little clean up sanding. I took everything down to 240 grit after the cut, before moving the canopy.

The cutting wasn't as bad as others have made it out to be.It is only a (very expensive) piece of plastic. It isn't like it is a Ferrari or anything. Like everything else on this build, I was stressing over it and it turned out to be not worthy. With all the others writing of their experience, that background helped a lot. (Thank you)

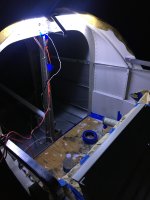

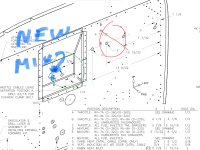

I taped the canopy to the frame for a fit check using wire as a Sika spacer. Seems I have a few more trim cuts to make, so I figure another whole day in the sun and then it will be ready to bond.

I am thinking of not using the trim piece that sits on the outside, down the middle spine. It seems with the Sika bonding method, there is no need for this strip. But

I think I will need to bond on a thrust washer for the handle thou.

Today was a warm day, perfect for canopy work.

This weekend was all about cutting the canopy down to size. The on-line experts suggested to use the Dremel Max Saw. This worked out very well. However, they recommended the SM500 plastic blade, I found this to be a really coarse cut. I chose to use the SM510 metal blade. This blade is just like the cut off wheel Van's supplies in the kit, but for the Max Saw. With this blade, if the cuts are made carefully, there is very little clean up sanding. I took everything down to 240 grit after the cut, before moving the canopy.

The cutting wasn't as bad as others have made it out to be.It is only a (very expensive) piece of plastic. It isn't like it is a Ferrari or anything. Like everything else on this build, I was stressing over it and it turned out to be not worthy. With all the others writing of their experience, that background helped a lot. (Thank you)

I taped the canopy to the frame for a fit check using wire as a Sika spacer. Seems I have a few more trim cuts to make, so I figure another whole day in the sun and then it will be ready to bond.

I am thinking of not using the trim piece that sits on the outside, down the middle spine. It seems with the Sika bonding method, there is no need for this strip. But

I think I will need to bond on a thrust washer for the handle thou.