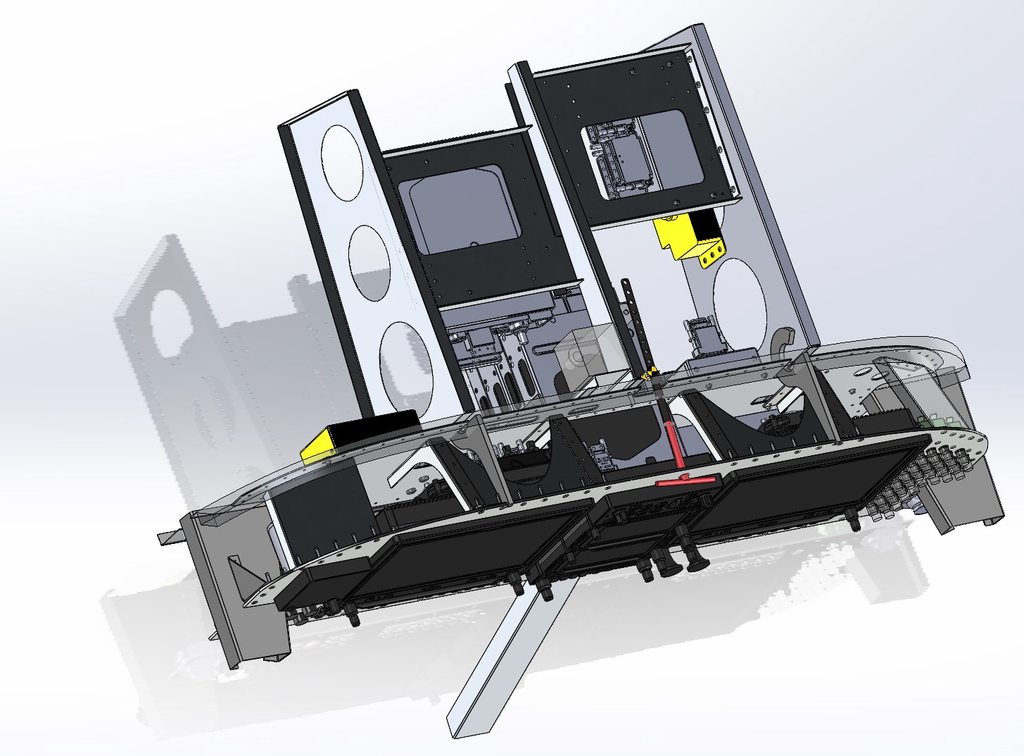

I recently finished designing and installing a dual display setup in my RV-6. The normal panel installation has two formers supporting the panel which perfectly interfere with where the displays would go in a dual setup, so some creative bracketry was required - the RV-7 structure is significantly different in this area from what I can tell, and not so much suffering is required.

It isn't clear to me how common an installation this is, so I wanted to share in case anyone else is thinking of doing something like this and is curious about what is entailed.

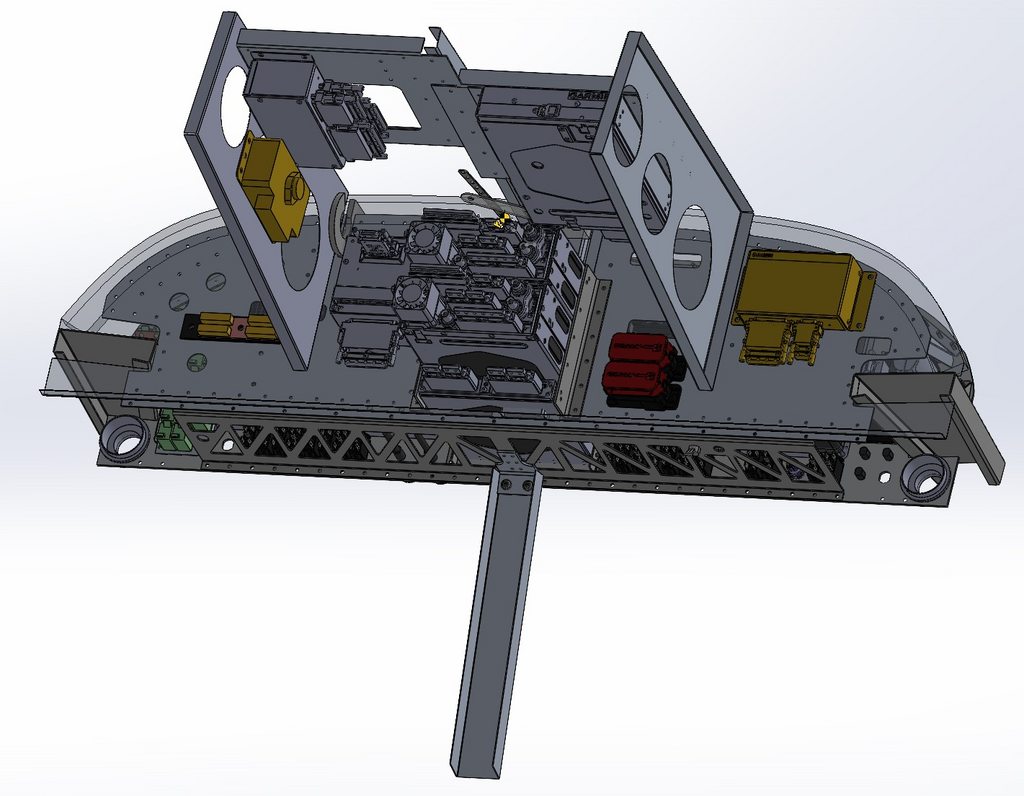

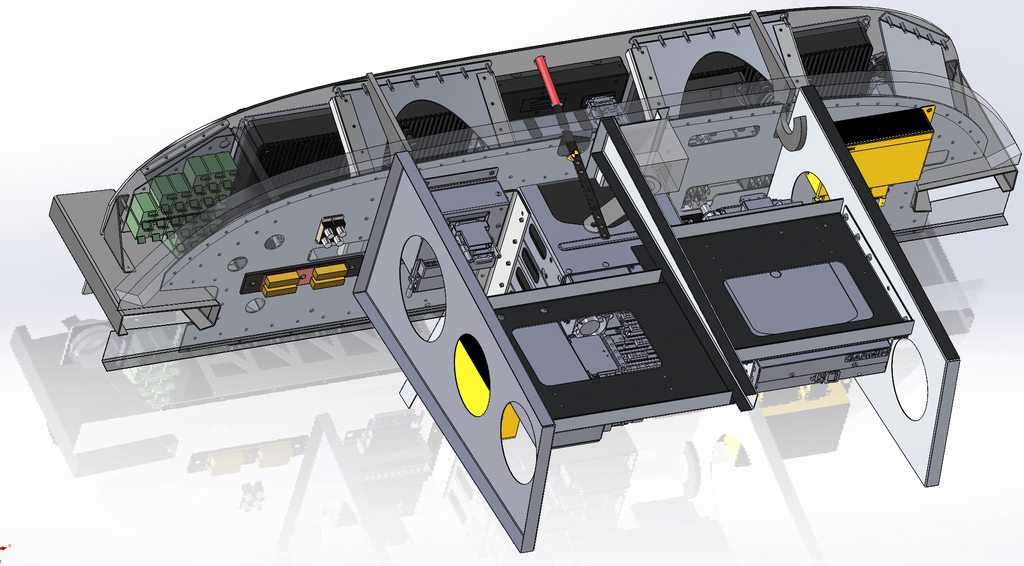

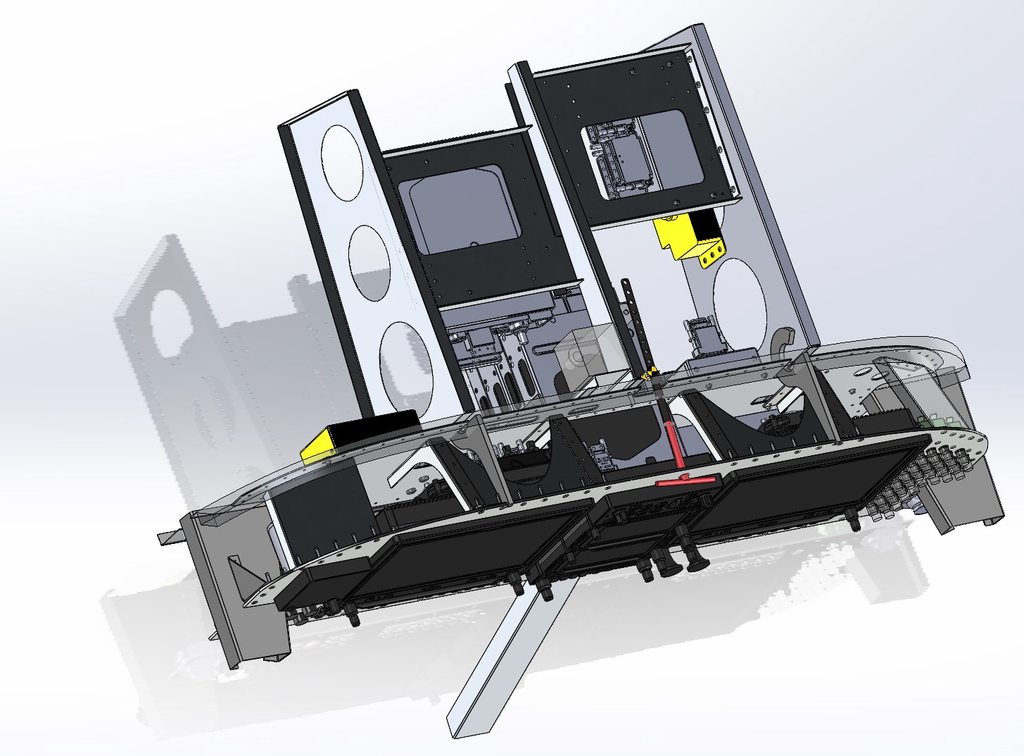

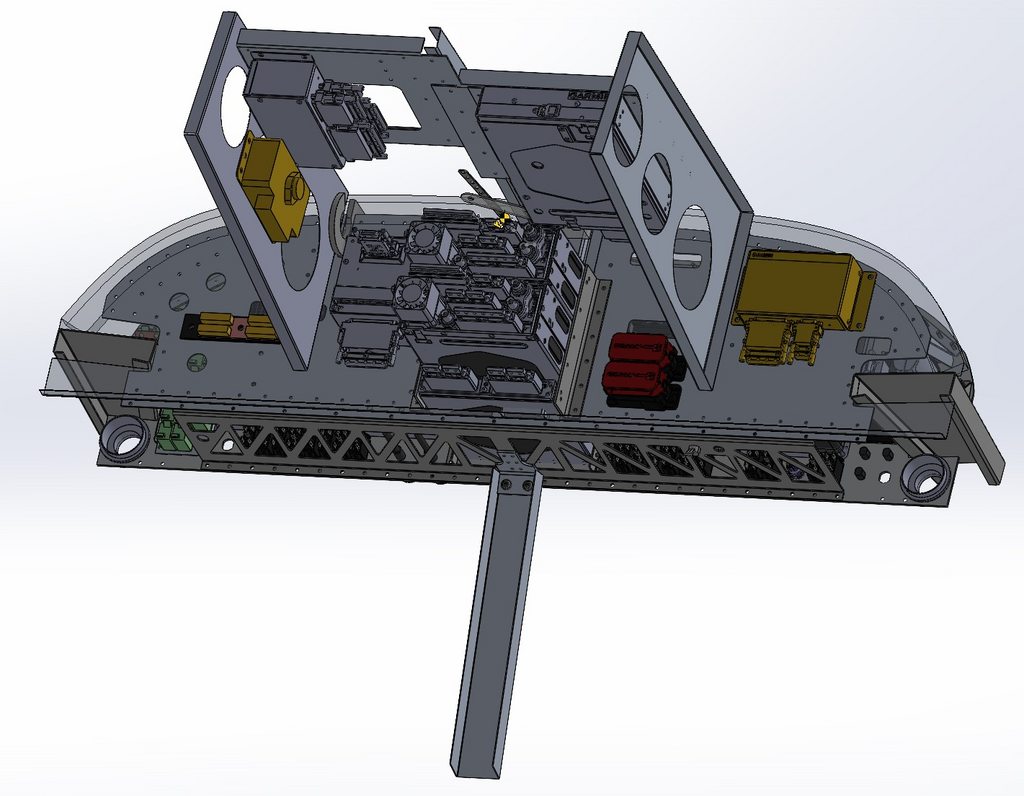

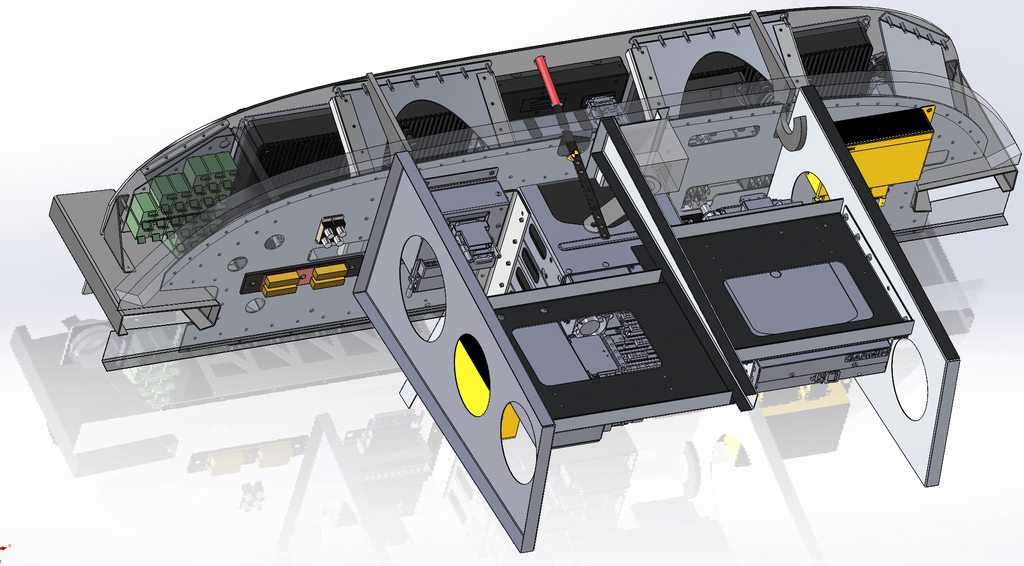

To make sure everything fit I made extensive use of CAD and had the metal fabricated from drawings by a sheet metal service. This was an extremely good allocation of time as the metal fabrication costs for this project were under $2000, including bending, the engraved and powder-coated main panel, and conversion coating on the bracketry.

I am happy to answer any questions.

Some pictures:

It isn't clear to me how common an installation this is, so I wanted to share in case anyone else is thinking of doing something like this and is curious about what is entailed.

To make sure everything fit I made extensive use of CAD and had the metal fabricated from drawings by a sheet metal service. This was an extremely good allocation of time as the metal fabrication costs for this project were under $2000, including bending, the engraved and powder-coated main panel, and conversion coating on the bracketry.

I am happy to answer any questions.

Some pictures:

Last edited: