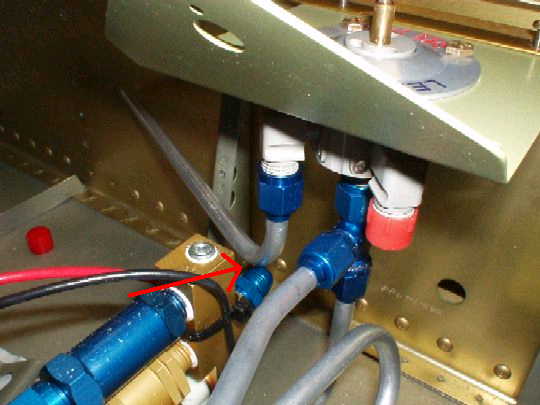

Is anybody using the Andair FS20X7T fuel selector valve (that's the version Van's sells) with fuel injected engine (i.e. with the Airflow Performance high pressure fuel pump that Van's sells)? I can't seem to make the geometry work.

The fuel line to the fuel selector from the right wing tank interferes with the aft fitting on the fuel pump's manifold. I think there's just no way to make the bend in the tubing tight enough as it comes off the fuel selector to avoid this interference. Am I wrong?

I've also looked at rotating the fuel selector's fitting 90 degrees so it's facing aft/outboard instead of down. But then the fuel line will interfere with the side cover panel.

What am I missing? It seems like this installation might only work with the Andair banjo fittings. But I thought this version of the fuel selector and fittings were especially designed for the RV-7 installation. Maybe just not with the high pressure fuel pump?

Anybody who's made this work, I'd love to hear how you did it. Or better yet see some photos. Thanks!

The fuel line to the fuel selector from the right wing tank interferes with the aft fitting on the fuel pump's manifold. I think there's just no way to make the bend in the tubing tight enough as it comes off the fuel selector to avoid this interference. Am I wrong?

I've also looked at rotating the fuel selector's fitting 90 degrees so it's facing aft/outboard instead of down. But then the fuel line will interfere with the side cover panel.

What am I missing? It seems like this installation might only work with the Andair banjo fittings. But I thought this version of the fuel selector and fittings were especially designed for the RV-7 installation. Maybe just not with the high pressure fuel pump?

Anybody who's made this work, I'd love to hear how you did it. Or better yet see some photos. Thanks!