Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mounting elevators; is this normal?

- Thread starter KMinor

- Start date

Flyin'Bryan

Well Known Member

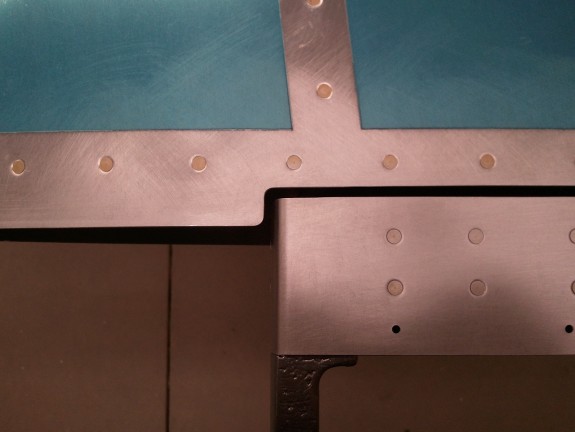

Looks pretty normal to me...

Kevin, take a look at this post in my blog - looks pretty similar to what I marked and trimmed. Just make sure to allow for a radius and the all- important gap for clearance of the elevator counter balance arm.

http://bryansrv8project.blogspot.com/2012/03/4585-hours-turned-center-bearing-drill.html

Kevin, take a look at this post in my blog - looks pretty similar to what I marked and trimmed. Just make sure to allow for a radius and the all- important gap for clearance of the elevator counter balance arm.

http://bryansrv8project.blogspot.com/2012/03/4585-hours-turned-center-bearing-drill.html

Oops! Obviously, -8 builders would know better.  As a -10 builder, we never needed this sort of trimming on the Al. Fiberglass was another matter and required lots of trimming.

As a -10 builder, we never needed this sort of trimming on the Al. Fiberglass was another matter and required lots of trimming.

Burning Man was quite an experience! I can't recommend it enough. I had seen a friend of mine land in the middle of the desert and had taken a photo. I knew i had to land in the desert too. However, to be safe, i decided to land during the event when the temporary airport and runway is setup, 88NV. It was one of my more challenging but absolutely FUN flying experiences yet. I still remember the approach to the playa and seeing several 1000 ft tall twisters spinning nearby.

The event itself was incredible, unique, nothing else like it, and the icing on the cake. I thought i would just check it off the bucket list, but i am hooked. I definitely plan to go again. The event is too big to experience on a single trip. It was some of the most fun i have ever had but too hard to put into words. You just have to go experience it!

j

j

Feel free to PM me about it further!

Jae

Burning Man was quite an experience! I can't recommend it enough. I had seen a friend of mine land in the middle of the desert and had taken a photo. I knew i had to land in the desert too. However, to be safe, i decided to land during the event when the temporary airport and runway is setup, 88NV. It was one of my more challenging but absolutely FUN flying experiences yet. I still remember the approach to the playa and seeing several 1000 ft tall twisters spinning nearby.

The event itself was incredible, unique, nothing else like it, and the icing on the cake. I thought i would just check it off the bucket list, but i am hooked. I definitely plan to go again. The event is too big to experience on a single trip. It was some of the most fun i have ever had but too hard to put into words. You just have to go experience it!

Feel free to PM me about it further!

Jae

Last edited:

AirbusPilot

Well Known Member

I have build two 8 empenage and yes you have to trim, absolutely normal

cka357

Active Member

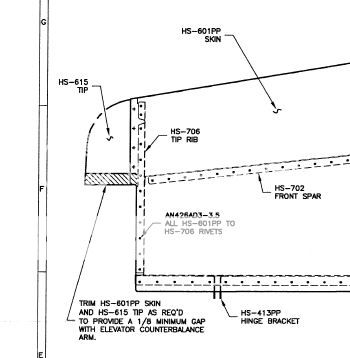

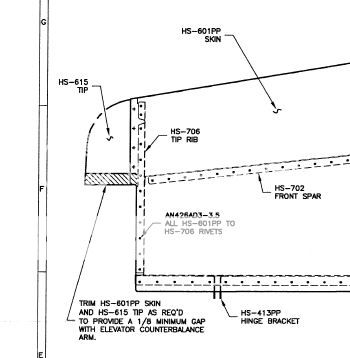

Elevator to Horizontal Stabilizer Tip Clearance

Above is a clip of the drawing. I did have to cut out the area as you are indicating on my 7 Emp. Make sure to square everything up before removing the material. It's ok to use multiple cuts and a file to sneak up on the spacing.

Chuck

Above is a clip of the drawing. I did have to cut out the area as you are indicating on my 7 Emp. Make sure to square everything up before removing the material. It's ok to use multiple cuts and a file to sneak up on the spacing.

Chuck

Last edited:

Ralph Inkster

Well Known Member

Before you trim- & you have adjusted your elevator hinge rod end bearings to proper alignment, use those tabs to align the elevators for match drilling the bolt hole in the elevator control arms.

KMinor

Active Member

I'm glad you brought that up, because I asked Van's that question in my email too. Their response was if I was certain the elevator trailing edges were in trail with the stab, and if the trailing edges were even, then go ahead and drill. I've read several builder's logs about this issue. The consensus that I'm coming up with is that its better to have the elevators swing freely to verify that they are in trail. I've read that many people clamp down the counterweight arms to the HS and call it in trail (those tabs have mine effectively clamped down now). The problem, it seems, is that some amount of twist can be introduced during the construction of the counterweight arms, so they might look even with the HS, but the trailing edge not be in trail with the extended chord line of the HS. I'm not going to get in a hurry to trim the tabs just yet. I'm going to tweak the alignment of the rod end bearings, and do more research into how to check the alignment with the extended chord line. I've seen it suggested to wait until the tail is mounted on the fuselage before drilling the control horns for this reason.

Paul Tuttle

Well Known Member

Same as mine.

KMinor

Active Member

I'm still tweaking the rod end bearings to square the gaps, but I thought I'd do a preliminary check on the trail with the chord line using a laser level. This side at least looks to be in pretty good shape and if nothing changes with the bearing adjustments, I'm going to drill the control horn before trimming the HS skin. I'm learning as I go, though, so I welcome any suggestions. This seems too simple.

Last edited:

rzbill

Well Known Member

You will find (via here or talking with builders face to face) that Van does revise over time the parts sent with the kits.

This is one example. My kit had to be trimmed per the plans. Newer ones dont. Other examples of updates are the VS spar reinforcement lightening holes and the heater hole in the firewall.

This is one example. My kit had to be trimmed per the plans. Newer ones dont. Other examples of updates are the VS spar reinforcement lightening holes and the heater hole in the firewall.

bret

Well Known Member

You will find (via here or talking with builders face to face) that Van does revise over time the parts sent with the kits.

This is one example. My kit had to be trimmed per the plans. Newer ones dont. Other examples of updates are the VS spar reinforcement lightening holes and the heater hole in the firewall.

What heater hole? Just received my fuse kit and did not see a hole? But I did luck out on the VS

rzbill

Well Known Member

What heater hole? Just received my fuse kit and did not see a hole? But I did luck out on the VS

Interesting. I definitely remember that a 9A builder told me his firewall had the 2 " hole in it and I thought other local 7As had said similar.

Vans inventory not FIFO maybe?