Dave Stephens

Active Member

Thanks for posting them!

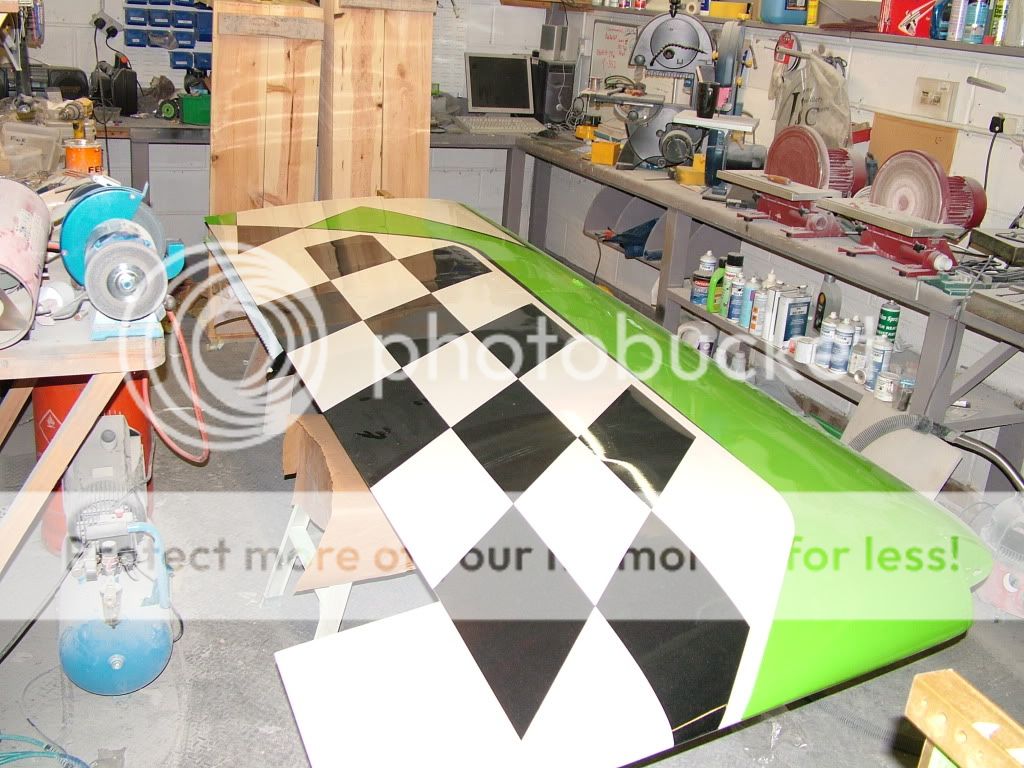

I took delivery of this kit in June this year, and have been working on it full time + since then! prop went on today (MT 3 blade C/S) and will be running the engine up later in the week.

Dave

I took delivery of this kit in June this year, and have been working on it full time + since then! prop went on today (MT 3 blade C/S) and will be running the engine up later in the week.

Dave