Hi Glenn from New Zealand. In Palmerston North. ordered a standard build RV7 kit...tail dragger. bit of a wait because as you all probably know...there is a lead time...i'm told 4 months for the tail and 7 for the wings and fuse. Im one month down from order.

I have tooled up mostly from Cleaveland Tools. They are on the way. All the standard RV7 stuff for a kit CT has plus the pneumatic squeezer.

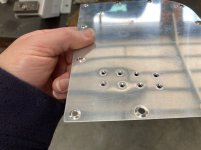

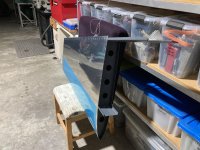

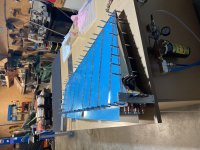

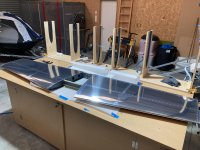

I was given an installation kit to make a drdt2 Dimpler and I have made the frame...used 3"x6" x1/4" thick for the frame. (thats 75mm x 150mm x 6mm for us kiwis) but i'm adopting the imperial lingo as much as possible!

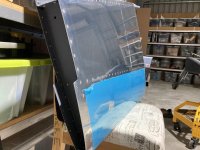

The Dimpler frame is at the powder coaters...

I also have some stuff from the yard store and browns tools too. new 2x Sioux rivet gun...3x used sioux and a used 1412 sioux drill. Borrowing clecos from here in nz as shipping is quite a bit on those. I have a 1.5" and 3" yoke....all the Cleaveland dimple dies, drills, reamers, hand tools, back rivet set, swivel mushroom set, micro stop needle bearing cage, single flute countersinks, etc etc. Most tools are CT. I wanted top quality gear to build with and I think I've done ok.

Vans are sending some clecos, a scotch brite wheel and some practice kits with my empennage kit.

So my build will be.

lycoming 180 hp M1B with cold air induction and EIS to give closer to 190 HP....(thanks lycoming for the 13% increase...DOH!) and a cato three blade fixed.

Ive thought long and hard about the whole CS versus fixed debate but Im not hugely into aerobatics nor making a short field machine and like the "keep it simple stupid" approach. Yes Im aware of the whole debate but I have 21000 flight hours flying boeing and airbus for the last 21 years so I can manage energy and don't need extra stuff to play with in the cockpit (oh except a nice electronic avionics package!)

I have tooled up mostly from Cleaveland Tools. They are on the way. All the standard RV7 stuff for a kit CT has plus the pneumatic squeezer.

I was given an installation kit to make a drdt2 Dimpler and I have made the frame...used 3"x6" x1/4" thick for the frame. (thats 75mm x 150mm x 6mm for us kiwis) but i'm adopting the imperial lingo as much as possible!

The Dimpler frame is at the powder coaters...

I also have some stuff from the yard store and browns tools too. new 2x Sioux rivet gun...3x used sioux and a used 1412 sioux drill. Borrowing clecos from here in nz as shipping is quite a bit on those. I have a 1.5" and 3" yoke....all the Cleaveland dimple dies, drills, reamers, hand tools, back rivet set, swivel mushroom set, micro stop needle bearing cage, single flute countersinks, etc etc. Most tools are CT. I wanted top quality gear to build with and I think I've done ok.

Vans are sending some clecos, a scotch brite wheel and some practice kits with my empennage kit.

So my build will be.

lycoming 180 hp M1B with cold air induction and EIS to give closer to 190 HP....(thanks lycoming for the 13% increase...DOH!) and a cato three blade fixed.

Ive thought long and hard about the whole CS versus fixed debate but Im not hugely into aerobatics nor making a short field machine and like the "keep it simple stupid" approach. Yes Im aware of the whole debate but I have 21000 flight hours flying boeing and airbus for the last 21 years so I can manage energy and don't need extra stuff to play with in the cockpit (oh except a nice electronic avionics package!)