Draker

Well Known Member

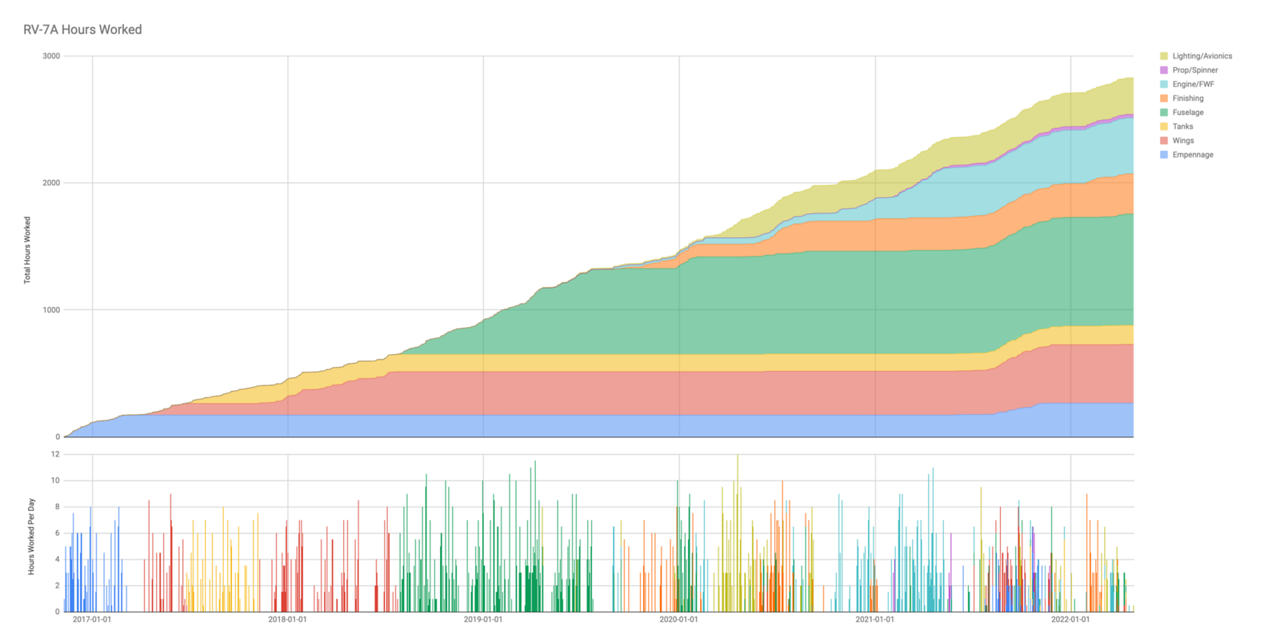

Thought it would be fun to start one of these threads and take a trip down memory lane. I'll post a few major milestones from my RV-7A build and see if I can keep it up to date!

2016-11-12: Obligatory first rivets:

2016-12-10: First complete assembly (HS):

2017-02-19: First mod of many: trim tab riblets:

2017-10-29: First job finished that I never want to do again:

2017-12-22: First time I wanted to quit building:

2018-07-08: Wings done (with witness dog):

2019-01-01: First panicked call to Van's thinking I ruined the whole project

2019-03-09: Canoe flip:

2019-03-30: First airplane noises with copilot:

2016-11-12: Obligatory first rivets:

2016-12-10: First complete assembly (HS):

2017-02-19: First mod of many: trim tab riblets:

2017-10-29: First job finished that I never want to do again:

2017-12-22: First time I wanted to quit building:

2018-07-08: Wings done (with witness dog):

2019-01-01: First panicked call to Van's thinking I ruined the whole project

2019-03-09: Canoe flip:

2019-03-30: First airplane noises with copilot: