Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weigh in today- forgot to measure gear arms

- Thread starter Blain

- Start date

Is it safe to use the sample arms in the manual?

It is if you don't really care how precise the C.G. calculation is.... the RV-8 probably has the highest possibility of variation because of how the main gear legs attach.

Why not just do it now? The airplane doesn't know whether it is up on scales or not. As long as you position the airplane level as it was while on the scales you will get the proper result. It is actually easier to do with the airplane not on scale pads.

Bob Kuykendall

Well Known Member

... Is it safe to use the sample arms in the manual?...

I sure wouldn't. It's pretty easy for the main gear axle station to be a half inch off, and that can make a pretty big difference in the CG location. In the HP-series gliders I support I have seen main gear positions varying by about an inch depending on where the mounting pivots were placed and how long the oleo restraining cable is.

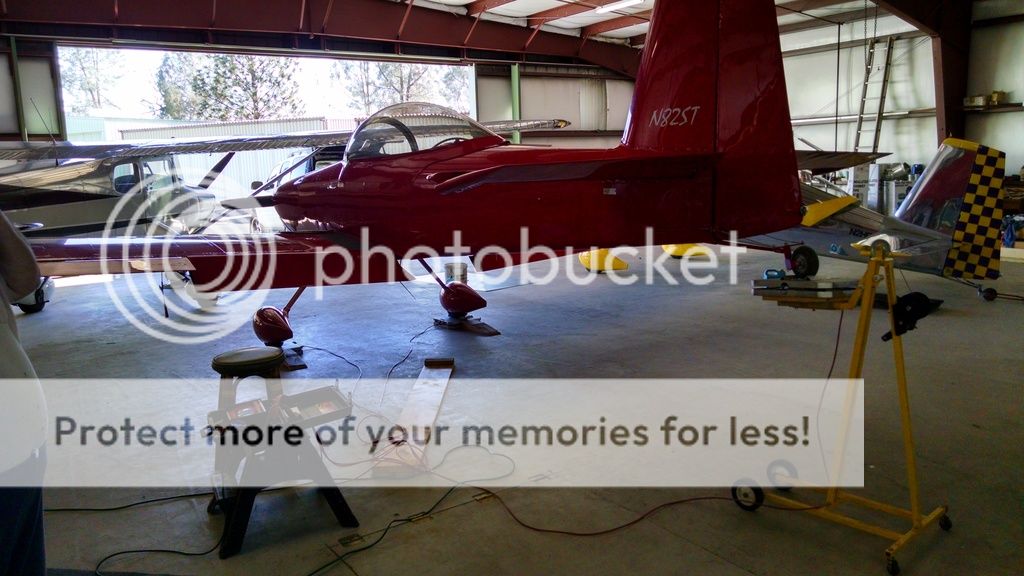

Edit add: I love that tailwheel scale support stand, that is genius! Every EAA chapter oughta have one of those.

FYI - Nobody ever needs to raise the tailwheel while trying to balance it on a scale at the same time.

1. Weigh the whole aircraft in three-point attitude.

2. Raise the tailwheel off the rear scale (just pick it up and put it flat in your hands) until the fuselage reads level.

3. Have someone read the two main gear again.

4. Tail weight is total from (1) minus total from (3).

Math is your friend.

1. Weigh the whole aircraft in three-point attitude.

2. Raise the tailwheel off the rear scale (just pick it up and put it flat in your hands) until the fuselage reads level.

3. Have someone read the two main gear again.

4. Tail weight is total from (1) minus total from (3).

Math is your friend.

Toobuilder

Well Known Member

FYI - Nobody ever needs to raise the tailwheel while trying to balance it on a scale at the same time.

1. Weigh the whole aircraft in three-point attitude.

2. Raise the tailwheel off the rear scale (just pick it up and put it flat in your hands) until the fuselage reads level.

3. Have someone read the two main gear again.

4. Tail weight is total from (1) minus total from (3).

Math is your friend.

it has been my experience that the math does not always work out that way due to the variation in the scales. If you do try it that way, I'd recommend a series of 3 weighings, rotating the main gear pads each time and if close, do the average. That should flush out any outlier readings.

I generally weigh the airplane 3 times in the 3 point attitude, and 3 times level before I settle on the final numbers.

And yes, you can measure arms before or after.

You're mixing two different things... First, the math *has* to work out that way, it's gravity and trigonometry, the laws of which are pretty much irrefutable.it has been my experience that the math does not always work out that way due to the variation in the scales.

...

I generally weigh the airplane 3 times in the 3 point attitude, and 3 times level before I settle on the final numbers.

Second, the issue with scale variation is an issue with scale calibration. If they don't all match, rotating them around just moves the error around and you will never get a reading more accurate than the average error.

Mike S

Senior Curmudgeon

Sounds like I need to borrow the jack

Stop by on your way home.

You did a great job on the plane.

And, congrats on the check ride

Toobuilder

Well Known Member

You're mixing two different things... First, the math *has* to work out that way, it's gravity and trigonometry, the laws of which are pretty much irrefutable.

Second, the issue with scale variation is an issue with scale calibration. If they don't all match, rotating them around just moves the error around and you will never get a reading more accurate than the average error.

Well there are irrefutable laws and then there is practical reality.

The reason for various weighings is to ensure repeatability - the oft overlooked "sanity check". If you discover an outlier, you correct it before continuing on. If you weigh once, you just go on faith the load cells are right.

Blain

Well Known Member

it has been my experience that the math does not always work out that way due to the variation in the scales. If you do try it that way, I'd recommend a series of 3 weighings, rotating the main gear pads each time and if close, do the average. That should flush out any outlier readings.

I generally weigh the airplane 3 times in the 3 point attitude, and 3 times level before I settle on the final numbers.

And yes, you can measure arms before or after.

Just considering the accuracy of this method. Wouldn't the weight forward of the pivot point change the weight on the tail Wheel? Meaning as the tail comes up mass forward of the gear (pivot point) increases, countering the weight on the tail?

Toobuilder

Well Known Member

Absolutely! The only reason I weigh it in the 3 point attitude is to get an overall picture of basic weight in a stable, easy to verify position. The individual wheel weights are meaningless in 3 point, but if the overall weight is different in the level attitude, then it's time to do some investigating.

az_gila

Well Known Member

You're mixing two different things... First, the math *has* to work out that way, it's gravity and trigonometry, the laws of which are pretty much irrefutable.

Second, the issue with scale variation is an issue with scale calibration. If they don't all match, rotating them around just moves the error around and you will never get a reading more accurate than the average error.

My borrowed race car scales only read to the pound and a quick check by standing on them one at a time shows any inconsistency. Since they all read the same value I don't think I'll do the "swap around" trick.

Robert Anglin

Well Known Member

Yep!

I would have to go with Scott on this one for sure. We found that it was best to take the wheel pants off and get all the Datum lengths logged first. Then put the pants back on and weigh the aircrafts three stations after that. At the main wheel spindles we saw maybe 3/8" of difference. Not much but we now have a good set of numbers to work with for the weigh-in.

Oh, we also found that it is a good idea to calibrate the scales before you weigh. Just take one of those nice digital bath scales, stand on it then stand on the scale you are using to weight the aircraft. Match that number and you will be off to the races. Hope this help, just two pennies in a pocket, Yours R.E.A. III #80888

It is if you don't really care how precise the C.G. calculation is.... the RV-8 probably has the highest possibility of variation because of how the main gear legs attach.

Why not just do it now? The airplane doesn't know whether it is up on scales or not. As long as you position the airplane level as it was while on the scales you will get the proper result. It is actually easier to do with the airplane not on scale pads.

I would have to go with Scott on this one for sure. We found that it was best to take the wheel pants off and get all the Datum lengths logged first. Then put the pants back on and weigh the aircrafts three stations after that. At the main wheel spindles we saw maybe 3/8" of difference. Not much but we now have a good set of numbers to work with for the weigh-in.

Oh, we also found that it is a good idea to calibrate the scales before you weigh. Just take one of those nice digital bath scales, stand on it then stand on the scale you are using to weight the aircraft. Match that number and you will be off to the races. Hope this help, just two pennies in a pocket, Yours R.E.A. III #80888

Yes, exactly... But that's okay. All you care about is the weight on the wheels when the aircraft is in it's level configuration.Just considering the accuracy of this method. Wouldn't the weight forward of the pivot point change the weight on the tail Wheel? Meaning as the tail comes up mass forward of the gear (pivot point) increases, countering the weight on the tail?

The *total* weight on the three points will not change regardless of attitude. They will always add to the same number. Weighing in three-point and then raising the tail lets you determine the tail weight without trying to balance a scale on top of a jury-rigged hoist. (Total) minus (two mains in flying attitude) equals (tail in flying attitude).