I recently viewed some photos taken after a fuel starvation incident, and thought it might be good to pass along a tip for the new guys.

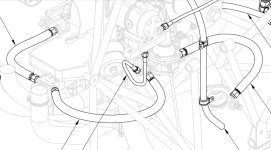

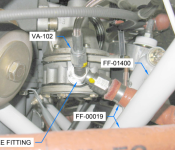

The builders' goal was to access the engine driven fuel pump outlet for a fuel pressure sender. He stacked a 90 degree pump outlet, an automotive aftermarket tee fitting (with female and male ends), and a 90 degree tube end on the hose to the servo.

There are at least two issues here. One, it's a string of fittings with a line leading off at a right angle to the primary thread axis. An offshoot line arranged that way can easily become a lever, providing torque to unscrew one of the connections.

Worse, it appears the servo hose was allowed to contact the engine mount tube, downstream of the tube end, which in addition to the above placed another potential turning moment on the stacked connections.

The combination was all but guaranteed to unscrew one of the fittings eventually, and in fact did so. The subsequent loss of fuel pressure resulted in a forced landing, and yes, it could have caught fire in flight.

There are lots of better ways to skin this cat, but for the new guys, the generally accepted EAB practice is to drill and tap the pump fitting for a straight steel nipple, 1/8" NPT to -3 or -4 flare, which couples to the sender hose. The sender hose cannot unscrew the pump fitting, or the servo hose. The modified fitting is so common that Aircraft Spruce sells them already tapped: https://www.aircraftspruce.com/catalog/eppages/lycomingfitting00783.php?clickkey=335909

Let's be careful out there.

-

The builders' goal was to access the engine driven fuel pump outlet for a fuel pressure sender. He stacked a 90 degree pump outlet, an automotive aftermarket tee fitting (with female and male ends), and a 90 degree tube end on the hose to the servo.

There are at least two issues here. One, it's a string of fittings with a line leading off at a right angle to the primary thread axis. An offshoot line arranged that way can easily become a lever, providing torque to unscrew one of the connections.

Worse, it appears the servo hose was allowed to contact the engine mount tube, downstream of the tube end, which in addition to the above placed another potential turning moment on the stacked connections.

The combination was all but guaranteed to unscrew one of the fittings eventually, and in fact did so. The subsequent loss of fuel pressure resulted in a forced landing, and yes, it could have caught fire in flight.

There are lots of better ways to skin this cat, but for the new guys, the generally accepted EAB practice is to drill and tap the pump fitting for a straight steel nipple, 1/8" NPT to -3 or -4 flare, which couples to the sender hose. The sender hose cannot unscrew the pump fitting, or the servo hose. The modified fitting is so common that Aircraft Spruce sells them already tapped: https://www.aircraftspruce.com/catalog/eppages/lycomingfitting00783.php?clickkey=335909

Let's be careful out there.

-

Attachments

Last edited: