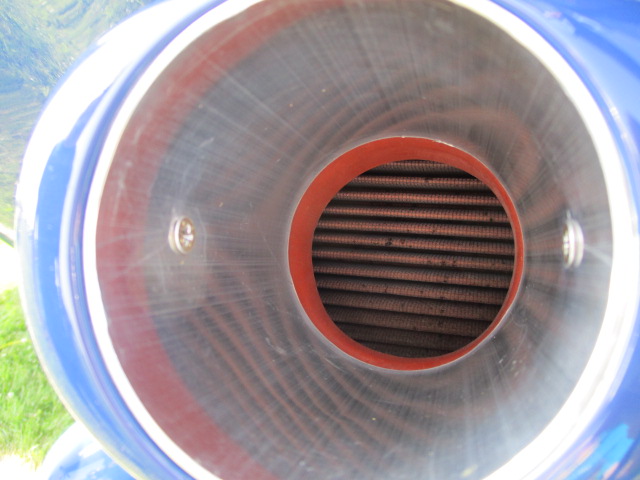

One of the best RV ideas I saw at OSH was this intake for an airbox with a large area K&N filter. The concept could probably be used with a modified Vans airbox for the vertical intake engines also.

The problem is how to put the lower cowl on the airplane while dealing with the connecting seals or ducts. Here the builder has fabricated an aluminum sleeve. It is inserted after the cowl is in place, slipping inside the orange duct leading to the airbox. It is then fixed into place in the cowl with two screws.

Am am deeply ashamed to say I can't remember whose airplane this was, despite talking with the builder for a few minutes. Claim it please, and kick me next time you see me

Great idea, and beautifully done.

The problem is how to put the lower cowl on the airplane while dealing with the connecting seals or ducts. Here the builder has fabricated an aluminum sleeve. It is inserted after the cowl is in place, slipping inside the orange duct leading to the airbox. It is then fixed into place in the cowl with two screws.

Am am deeply ashamed to say I can't remember whose airplane this was, despite talking with the builder for a few minutes. Claim it please, and kick me next time you see me

Great idea, and beautifully done.