Russ McCutcheon

Well Known Member

I didn?t know there was so much interest in Aircraft TIG welding hear on VAF tell I was trying to learn how to insert a photo in the forums and inserted a couple of weld photos in the test section, I got the help I needed for inserting photos but much to me surprise the photos of the welds drew a lot of attention and some questions.

1. We use W-20 size water cooled torches.

2. Lindy/Heliarc and Lincoln welders, however I have never used a TIG welder that didn?t work well so most anything out there should be pretty good.

3. Very important, we use a gas lens in the torch in place of a gas tip, the lens is a stack of very fine mesh screens that the gas (pure argon) is dispersed through and gives superior shielding over a gas tip. We test every lens we use buy attempting to weld with the electrode sticking out 3/4? past the end of the cup, if the lens fails this test it goes back or in the trash, many fail when new and others work for years and suddenly fail.

4. We use Esab-65 filler rod in 1/16? and 3/32? diameter, we have tried others with mixed results, Lincoln has an equivalent that is a close second to the Esab.

5. We use 1/16? 2% Thoriated tungsten, I am soon going to try some 2% Lanthanated as a substitute, we?ll see how that goes.

We run our torch cables/hoses over head to keep the floor clear and to protect the cables/hoses

We keep the welding machines on the back side of the wall in the back shop so we don't have to listen to them running all day.

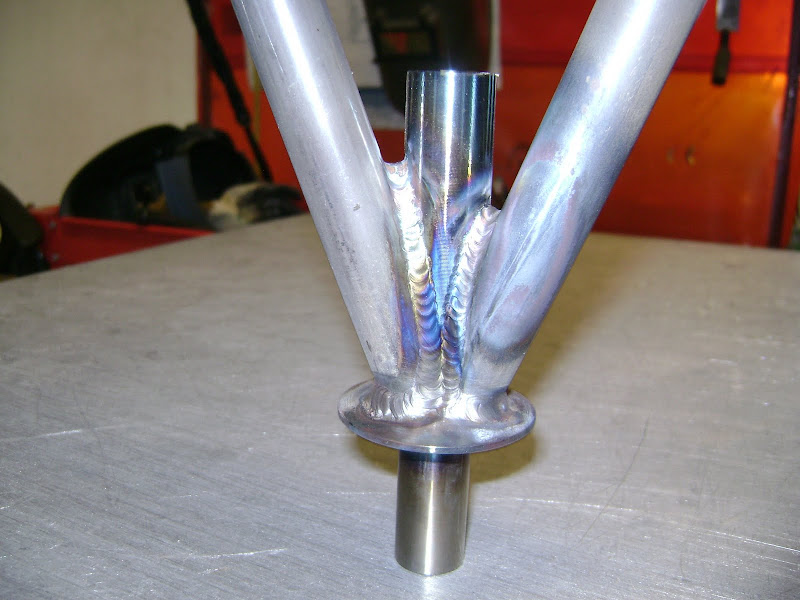

Some more weld photos.

1. We use W-20 size water cooled torches.

2. Lindy/Heliarc and Lincoln welders, however I have never used a TIG welder that didn?t work well so most anything out there should be pretty good.

3. Very important, we use a gas lens in the torch in place of a gas tip, the lens is a stack of very fine mesh screens that the gas (pure argon) is dispersed through and gives superior shielding over a gas tip. We test every lens we use buy attempting to weld with the electrode sticking out 3/4? past the end of the cup, if the lens fails this test it goes back or in the trash, many fail when new and others work for years and suddenly fail.

4. We use Esab-65 filler rod in 1/16? and 3/32? diameter, we have tried others with mixed results, Lincoln has an equivalent that is a close second to the Esab.

5. We use 1/16? 2% Thoriated tungsten, I am soon going to try some 2% Lanthanated as a substitute, we?ll see how that goes.

We run our torch cables/hoses over head to keep the floor clear and to protect the cables/hoses

We keep the welding machines on the back side of the wall in the back shop so we don't have to listen to them running all day.

Some more weld photos.