UnPossible

Well Known Member

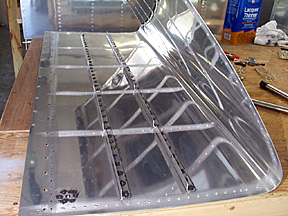

Hey - I am finally getting around to building a new tank after a bird strike last year. As my plane is a QB, this is my first experience with building tanks.

I have all the parts about ready to be riveted together. I am trying to find a good build log with step by step instructions for the prosealing / riveting. So far I have not found the successful search words (either I get way too many search results, or nothing).

Does any have a link to a detailed build log that shows the sealing/ riveting process in detail?

Thanks,

Jason

I have all the parts about ready to be riveted together. I am trying to find a good build log with step by step instructions for the prosealing / riveting. So far I have not found the successful search words (either I get way too many search results, or nothing).

Does any have a link to a detailed build log that shows the sealing/ riveting process in detail?

Thanks,

Jason