Question:

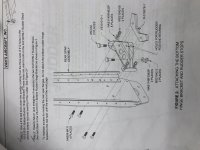

Just finishing up the vert stab and trying to bolt the lower rudder hinge bracket on. How do I determine the correct torque. Initially I thought it would be as easy as checking the table on page 5-20 of the plans but then I started reading about “friction drag/prevailing torque” and now I’m not sure. Also I don’t see an MS21042-08 even listed in the table. I’ve attached pictures of the plans and chart.

I feel like I’m missing something and this shouldn’t be hard.

Thanks,

Bryan

Just finishing up the vert stab and trying to bolt the lower rudder hinge bracket on. How do I determine the correct torque. Initially I thought it would be as easy as checking the table on page 5-20 of the plans but then I started reading about “friction drag/prevailing torque” and now I’m not sure. Also I don’t see an MS21042-08 even listed in the table. I’ve attached pictures of the plans and chart.

I feel like I’m missing something and this shouldn’t be hard.

Thanks,

Bryan