YankeeBravo

Member

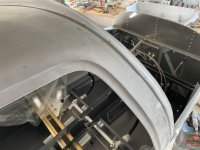

Good day, working on the doors and having the top part and side part flush with the structure I end up with the door being recessed more than 1/8 inches at the A pillar, it seems to be a lot.

Any thoughts or help welcome for the best way to fix it or avoid it...

Any thoughts or help welcome for the best way to fix it or avoid it...