FlyinTiger

Well Known Member

After a thorough prebuy examination on an RV with an IO-360-A1D with the help of an A&P I learned the following:

1. Take the serial number on the engine data plate and call Lycoming to get the manufactured date

2. Use the two week subscription paid for by an A&P to search for all applicable Airworthiness Directives (AD) by serial number and manufacture date.

3. Just because an engine was installed "new" doesn't mean it wasn't kept preserved for years, many years. The engine in my -7 was manufactured in 1983, stored pickled until 2003, then installed "new" in the plane I now own.

4. ADs may apply to an engine any time after they were manufactured. It doesn't matter when they were put into service. Given that it is much easier to perform work on an engine when it is out of the aircraft without accessories and exhaust mounted, is another great reason to check for ADs before installation. Additionally, the ADs should have been checked before an Airworthiness Certificate was issued for the aircraft, but don't assume the check was completed. It wasn't on this one.

5. Magneto inspection every 500 hours. If its not in the logbook it didn't happen. Bendix Magnetos are indefinitely serviceable. To make sure they are reliable and perform to a safe level, especially if it's a Dual Magneto, an IRAN is absolutely a good idea every 500 hours, though not "required."

6. Spark plugs. We clean, gap and rotate them at least once a year during the condition inspection. If there's corrosion on the exterior of the plugs or the center electrode is very worn (oval) it may be a good idea to replace the plugs. Also, if there's no indication they've been replaced then it might be time to bite the bullet.

7. Fluid hoses. The non-teflon hoses are good for about 8 years, then they must be replaced. Mine were 16 years old and performing admirably. They were all very stiff but I had no leaks. I understood these hoses needed to be replaced during the prebuy examination and the aircraft purchase price reflected that requirement.

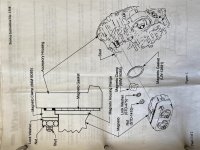

What I found was that the oil impeller gears, as indicated by serial number and date of manufacture, needed to be replaced. Lycoming determined they needed to be replaced and it is not optional, even on an experimental aircraft.

The plane I chose to buy had been flying for 16 years with the original gears that were installed at the Lycoming factory in 1983 without incident. Ooops. Those 534 hours are in the past... Moving forward I made it right so it is truely airworthy and in a "safe condition for flight." FAR Part 43, Appendix D describes the scope and detail of the yearly condition inspection, I have no choice going forward.

1. Take the serial number on the engine data plate and call Lycoming to get the manufactured date

2. Use the two week subscription paid for by an A&P to search for all applicable Airworthiness Directives (AD) by serial number and manufacture date.

3. Just because an engine was installed "new" doesn't mean it wasn't kept preserved for years, many years. The engine in my -7 was manufactured in 1983, stored pickled until 2003, then installed "new" in the plane I now own.

4. ADs may apply to an engine any time after they were manufactured. It doesn't matter when they were put into service. Given that it is much easier to perform work on an engine when it is out of the aircraft without accessories and exhaust mounted, is another great reason to check for ADs before installation. Additionally, the ADs should have been checked before an Airworthiness Certificate was issued for the aircraft, but don't assume the check was completed. It wasn't on this one.

5. Magneto inspection every 500 hours. If its not in the logbook it didn't happen. Bendix Magnetos are indefinitely serviceable. To make sure they are reliable and perform to a safe level, especially if it's a Dual Magneto, an IRAN is absolutely a good idea every 500 hours, though not "required."

6. Spark plugs. We clean, gap and rotate them at least once a year during the condition inspection. If there's corrosion on the exterior of the plugs or the center electrode is very worn (oval) it may be a good idea to replace the plugs. Also, if there's no indication they've been replaced then it might be time to bite the bullet.

7. Fluid hoses. The non-teflon hoses are good for about 8 years, then they must be replaced. Mine were 16 years old and performing admirably. They were all very stiff but I had no leaks. I understood these hoses needed to be replaced during the prebuy examination and the aircraft purchase price reflected that requirement.

What I found was that the oil impeller gears, as indicated by serial number and date of manufacture, needed to be replaced. Lycoming determined they needed to be replaced and it is not optional, even on an experimental aircraft.

The plane I chose to buy had been flying for 16 years with the original gears that were installed at the Lycoming factory in 1983 without incident. Ooops. Those 534 hours are in the past... Moving forward I made it right so it is truely airworthy and in a "safe condition for flight." FAR Part 43, Appendix D describes the scope and detail of the yearly condition inspection, I have no choice going forward.

Attachments

Last edited: