Is it crazy to consider this idea:

Discard the stock fairings (don't use if not installed yet).

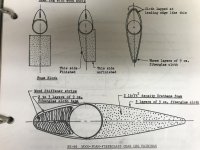

Shape relatively high-density foam in the shape of the gear leg fairings.

Make tunnel for brake line.

Cut out 1 to 2" long spaces for and add front and rear wood blocks front and back in upper, center and bottom positions (shaped as the cut-outs from the foam).

Wrap with fiberglass and resin.

Smooth to final finish.

Too much work?

Will never work?

Obviously proper alignment is critical as no adjustment possible once the foam, wood blocks and fiberglass are bonded with resin. Although one could wax the legs, but then how would the assembly be securely held in place?

I assume that foam would easily be crushed by the back-and-forth shimmy, thus the 6 wood blocks for each leg.

Finn

Discard the stock fairings (don't use if not installed yet).

Shape relatively high-density foam in the shape of the gear leg fairings.

Make tunnel for brake line.

Cut out 1 to 2" long spaces for and add front and rear wood blocks front and back in upper, center and bottom positions (shaped as the cut-outs from the foam).

Wrap with fiberglass and resin.

Smooth to final finish.

Too much work?

Will never work?

Obviously proper alignment is critical as no adjustment possible once the foam, wood blocks and fiberglass are bonded with resin. Although one could wax the legs, but then how would the assembly be securely held in place?

I assume that foam would easily be crushed by the back-and-forth shimmy, thus the 6 wood blocks for each leg.

Finn