RudiGreyling

Well Known Member

RVators,

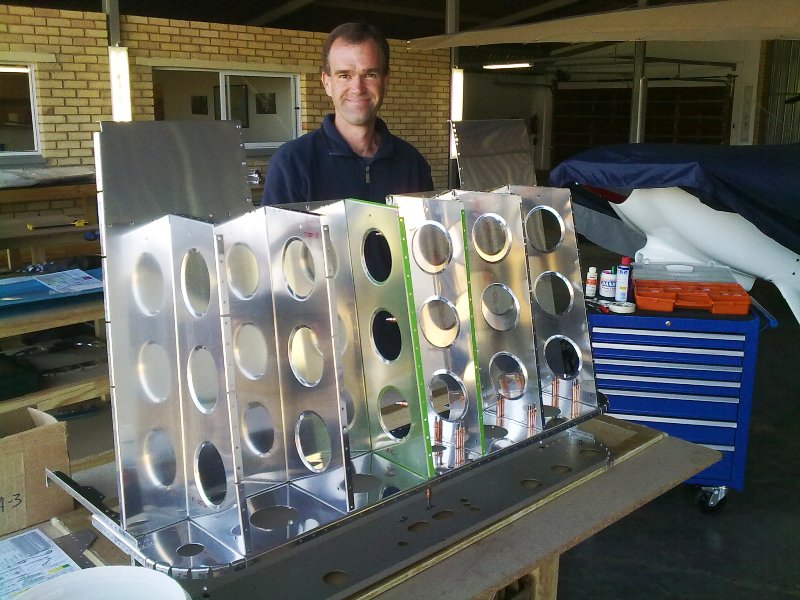

Some of you old Vansairforce.net timers might have seen me lurking around the RV12 group again, and might have wondered what I am doing here again seeing I got a flying RV7, half finished a RV12 sold it, and currently busy with a RV10

Well it is official: A group of 10 South Africans is going to build, learn and fly a RV12 We placed our orders for the Tailkit, Wings, Fuse and Finishkit last week on Vans and waiting its shipment.

We placed our orders for the Tailkit, Wings, Fuse and Finishkit last week on Vans and waiting its shipment.

I am helping 9 other grass roots builders and flyers to learn how to build and eventually fly a RV12. By pooling resources such as time and money together we are making it very affordable for these guys, who might never be able to do it on their own, build an aircraft and then learn to fly on it. Most of the guys don't have licenses yet, and very few has any building experience. Some of the guys are using it as a stepping stone into bigger and better things later on.

This is a non commercial venture and we are doing it under the watchful wing of our local EAA Chapter. We are hoping to set an example for guys following after us.

If you are interested to do the same, make contact with us, we have done a lot of good work, sorting out many niggles a group such as this might have, which you can learn from and build on.

Wish us luck!

Kind Regards

Rudi

EDIT:

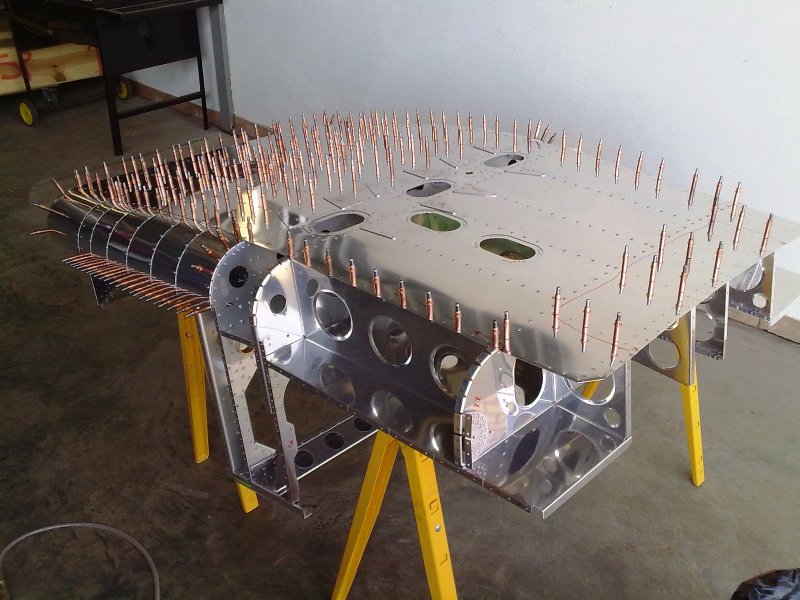

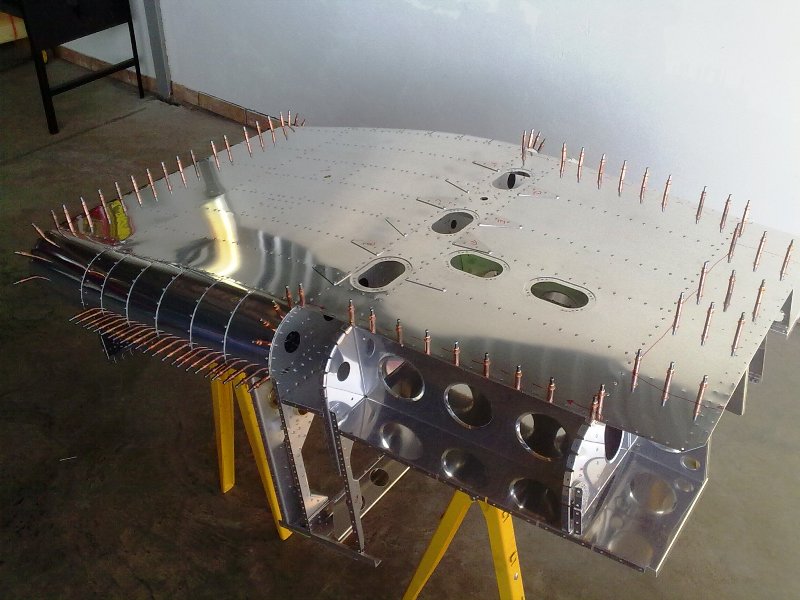

We Started and going strong. I Added all our build days under 1 heading for easy reference and will keep adding to this post as we continue the build.

Some of you old Vansairforce.net timers might have seen me lurking around the RV12 group again, and might have wondered what I am doing here again seeing I got a flying RV7, half finished a RV12 sold it, and currently busy with a RV10

Well it is official: A group of 10 South Africans is going to build, learn and fly a RV12

I am helping 9 other grass roots builders and flyers to learn how to build and eventually fly a RV12. By pooling resources such as time and money together we are making it very affordable for these guys, who might never be able to do it on their own, build an aircraft and then learn to fly on it. Most of the guys don't have licenses yet, and very few has any building experience. Some of the guys are using it as a stepping stone into bigger and better things later on.

This is a non commercial venture and we are doing it under the watchful wing of our local EAA Chapter. We are hoping to set an example for guys following after us.

If you are interested to do the same, make contact with us, we have done a lot of good work, sorting out many niggles a group such as this might have, which you can learn from and build on.

Wish us luck!

Kind Regards

Rudi

EDIT:

We Started and going strong. I Added all our build days under 1 heading for easy reference and will keep adding to this post as we continue the build.

Last edited: