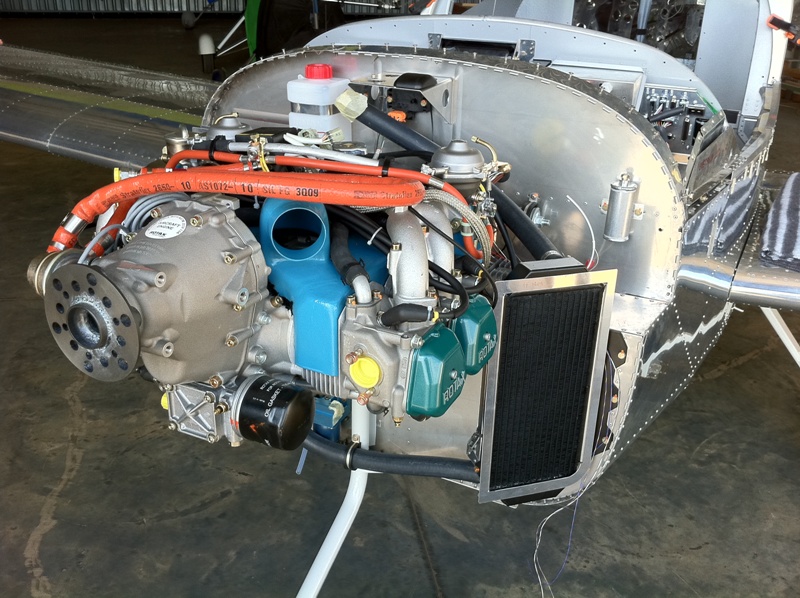

I have some vibrations at various RPMs. It is most prominent just above idle, and at various cruise RPMs. I can feel it by lightly touching the rudder pedals, or with a finger lightly against the canopy rail. It's not serious, but more than I would have expected. I liken it to the handlebar buzz that you get with some motorcycles. I did the carb balance, and it looks pretty good. I have removed the cowl, and can find no obvious areas of rubbing. I have even added an additional 1/4" of clearance for the left valve covers, which was almost touching before. The only noted issue is that the oil line hoses to the cooler seem short, and when I attach the cooler to the cowl, these hoses are maxed out. Surely these hoses couldn't carry vibration to the airframe?? By the way, I did move the oil cooler forward almost 3/4" by altering the inner shroud. This was to gain clearance to the muffler, and is probably why the hoses are a bit short.

Any thoughts would be greatly appreciated..................Tom

Any thoughts would be greatly appreciated..................Tom