Bayou Bert

Well Known Member

I guess it has been so long the thread I started with the same name

is gone.

Time for update and conclusion.

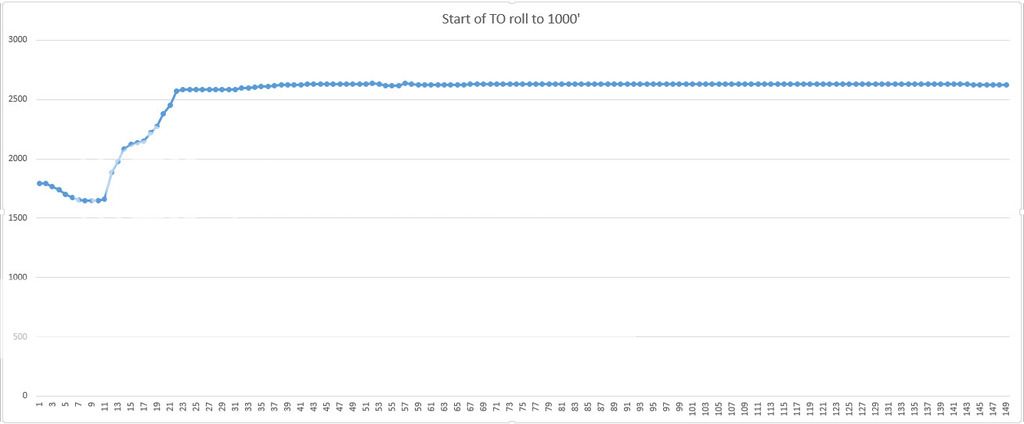

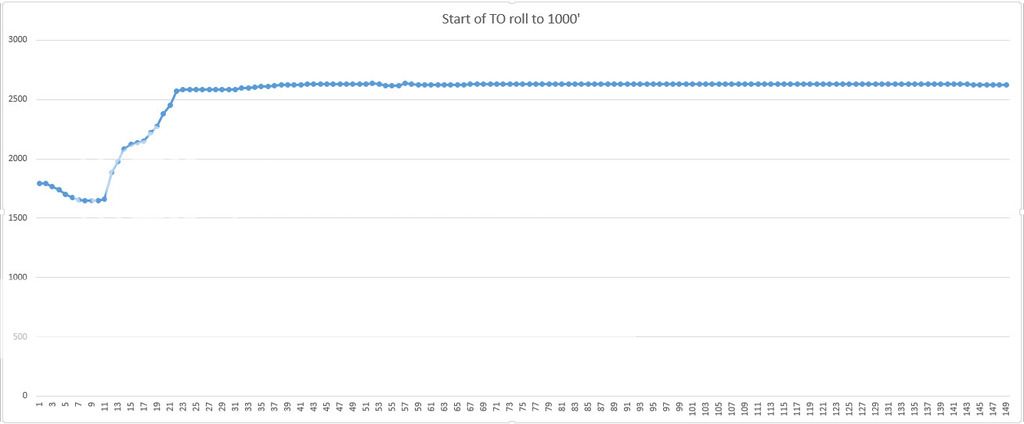

Below is graph of RPM of take off this morning, from start of roll to 1000'.

This is after changing crankshaft to one with the tube across the inside

with a slot cut in the center of the tube.

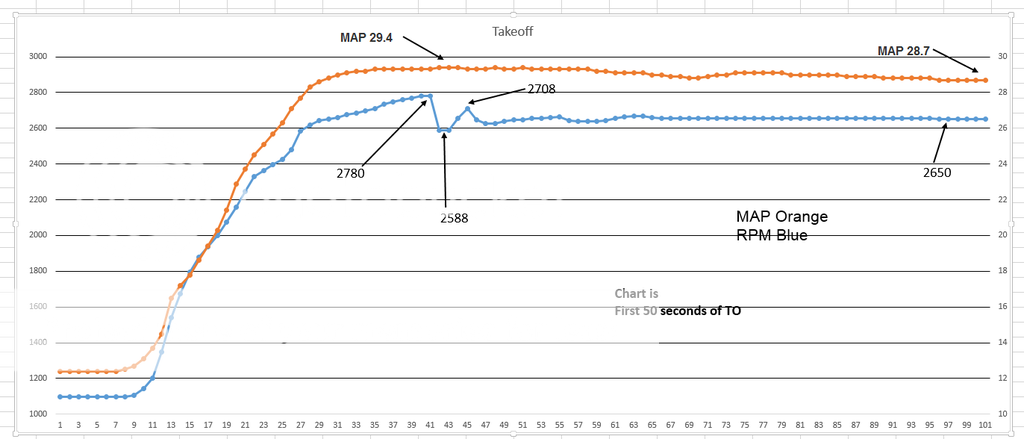

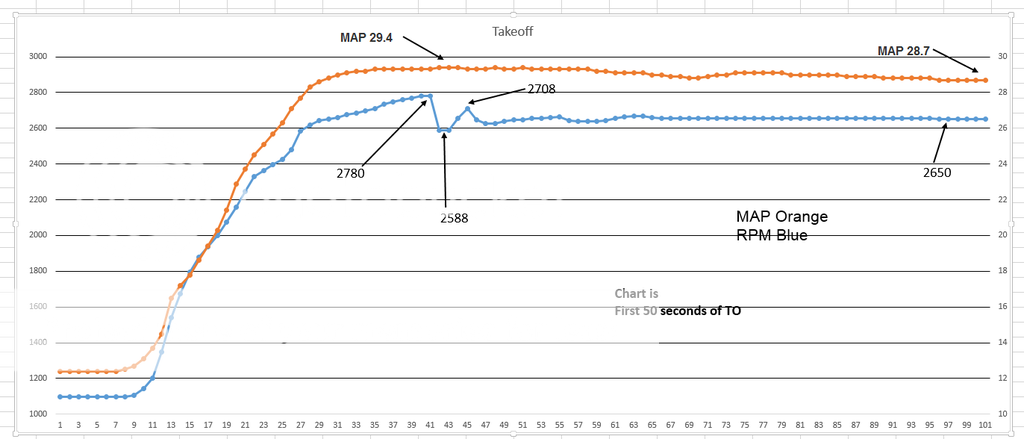

Below is graph of RPM of take off from start of roll for 30 seconds with the old crankshaft with only

a hole in crankshaft wall, no tube.

As you can see, no sag, no over speed to nothing. Just a nice steady RPM.

The only thing changed on the engine was the crank and new main bearings.

I put my MT governor back on for the first flight just to save labor if all

was good.

ALL IS GOOD!

Don Broussard (Cajunwings) and I made the flight. He put the prop

through a number of throttle changes, both up and down, the rpms showed

only slight deviations (30-40 rpm) and within seconds was back at set

rpm.

So, for constant speed operation, the crank has to have the cross tube.

No one we talked to could explain the physics of why, just that they had

never seen one work without the tube.

At this point I don't care, my engine, governor and prop are performing

as designed.

Thanks to all the people that helped, Aircraft Specialties, Hartzell and

Lycoming. Don for the rebuild and flying.

Now for a chance to just fly.

is gone.

Time for update and conclusion.

Below is graph of RPM of take off this morning, from start of roll to 1000'.

This is after changing crankshaft to one with the tube across the inside

with a slot cut in the center of the tube.

Below is graph of RPM of take off from start of roll for 30 seconds with the old crankshaft with only

a hole in crankshaft wall, no tube.

As you can see, no sag, no over speed to nothing. Just a nice steady RPM.

The only thing changed on the engine was the crank and new main bearings.

I put my MT governor back on for the first flight just to save labor if all

was good.

ALL IS GOOD!

Don Broussard (Cajunwings) and I made the flight. He put the prop

through a number of throttle changes, both up and down, the rpms showed

only slight deviations (30-40 rpm) and within seconds was back at set

rpm.

So, for constant speed operation, the crank has to have the cross tube.

No one we talked to could explain the physics of why, just that they had

never seen one work without the tube.

At this point I don't care, my engine, governor and prop are performing

as designed.

Thanks to all the people that helped, Aircraft Specialties, Hartzell and

Lycoming. Don for the rebuild and flying.

Now for a chance to just fly.

Last edited: