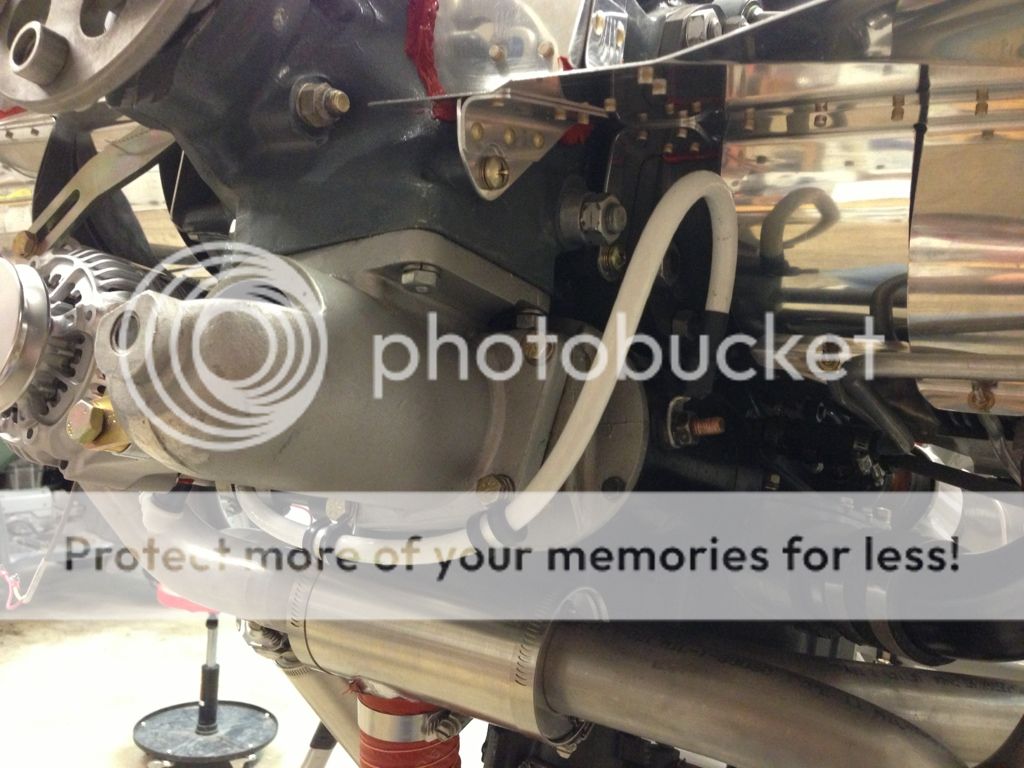

Here is what I borrowed from my local A&P

Here is my first crimp on 6 AWG for the Alt B lead

Does the crimp look correct?

Should I be doing one crimp and then rotate the terminal 90 degrees and crimping again?

I couldn't find any instructions online for the tool.

Thanks, Andy

Here is my first crimp on 6 AWG for the Alt B lead

Does the crimp look correct?

Should I be doing one crimp and then rotate the terminal 90 degrees and crimping again?

I couldn't find any instructions online for the tool.

Thanks, Andy