....now about that $1500 - $2000 :O

Ouch. That's not good.

By coincidence, I sent a request for a price quote to SWRI a few hours ago, but have not heard back yet.

....now about that $1500 - $2000 :O

A video on a test between mesh and standard filter.... https://www.youtube.com/watch?v=bVEbHTNWxoQ

Interesting video. I wonder if the paper filter had a magnet, and the mesh filter did not. Or would that have made any difference? What did they find in the samples from each filter as far as contaminants? In scientific research, we always want results to be verified by other people testing your results. One test is interesting but may not be the complete picture.

I wonder if we could get posts from people who have had oil analysis done with their oil changes who have changed to a mesh filter. Was there any difference? How did the analysis with the mesh compare to the paper filter? That would be real-world comparison.....

From the comment section in the video I am not so sure that the micron of the reusable filter was the same as the paper filter. I got the impression the paper filter had smaller micron specs.

...

I wonder if we could get posts from people who have had oil analysis done with their oil changes who have changed to a mesh filter. Was there any difference? How did the analysis with the mesh compare to the paper filter? That would be real-world comparison.....

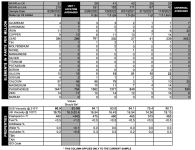

To make this a challenge, have a look to see if you can tell when I changed from the paper filter to the K&P stainless steel mesh.

You can also probably see when I started using Camguard.

I’ll start. Put me down for a C note if you want to crowd fund it. I want to know. I’ve been running these on 2 aircraft engines.Speaking of which, I got a note back from SWRI. It's $1500 to $1900 per filter for an ISO 4548-12 test. We need a generous benefactor, or we need to crowd fund it.

I’ll start. Put me down for a C note if you want to crowd fund it. I want to know. I’ve been running these on 2 aircraft engines.

I’ll start. Put me down for a C note if you want to crowd fund it. I want to know. I’ve been running these on 2 aircraft engines.

If you are not having the S15 filter tested against the aviation standard that Champion uses, what is the purpose of this test?

The thing to remember however is that while you could find out which filter is “best”, the real question is “what level of filtration is required to make my Lyclone go to TBO”. And that data has to come from elsewhere…probably Lycoming, but do they have any data to guide us?

I’m obviously pretty curious to see what the results of such tests might tell us - data rules! The thing to remember however is that while you could find out which filter is “best”, the real question is “what level of filtration is required to make my Lyclone go to TBO”. And that data has to come from elsewhere…probably Lycoming, but do they have any data to guide us?

This is kidn off in the same category of the “my oil hoses are good to 3,000 psi, not just a wimpy wimpy 2,000 psi”, when the oil pump can only put out 150 psi. 20 times the standard is better then 15 times the standard of course….but in reality it makes no difference. The bar is the bar, not “who can jump the highest bar”.

“my oil hoses are good to 3,000 psi, not just a wimpy wimpy 2,000 psi”, when the oil pump can only put out 150 psi. 20 times the standard is better then 15 times the standard of course….but in reality it makes no difference. The bar is the bar, not “who can jump the highest bar”.

Did you ask them?

Exactly.

But… I asked earlier in this thread, given that the FAA has already blessed the Challenger version of the S15, were we questioning for a practical reason or merely for the academic exercise?

I’m starting to lean even more heavily toward the latter…

but, unfortunately, I still have that nagging feeling the my O-320’s days are numbered because I’ve been using an S-15 for the past 25 hours!

I have read the post and I am trying to get the consensus from the engine gurus. I have used tempest oil filters and during the shortage of filters, I installed a S15 primarily based upon the information published that the S15 seemed to provide superior filtration. That seems to be the opinion of some and not the opinion of others.

For the non technical guys, does there seem to be a consensus if one is better than the other for engine longevity.

I have read the post and I am trying to get the consensus from the engine gurus. I have used tempest oil filters and during the shortage of filters, I installed a S15 primarily based upon the information published that the S15 seemed to provide superior filtration. That seems to be the opinion of some and not the opinion of others.

For the non technical guys, does there seem to be a consensus if one is better than the other for engine longevity.

………………………………….

I'll bet someone comes up with a good solution for a bypass filter for aircraft in the coming years. It won't be much more complex than our external oil coolers or inverted oil systems.

Back in the ‘80s when aircraft engines didn’t normally have oil filters, I had a FAA/PMA certified version of this toilet paper oil filter on my O-470. It worked great and was trouble free for the life of my engine.

I should have kept a sealed package of the the toilet paper with the FAA/PMA certification paperwork

https://www.amazon.com/Frantz-Filter-Universal-Bypass-Secret/dp/B09GW55FK1/ref=sr_1_1?crid=1XI5O67AWVYOG&keywords=Frantz+Filter+Universal+Bypass+Oil+Filter+Kit&qid=1699720200&sprefix=frantz+filter+universal+bypass+oil+filter+kit%2Caps%2C179&sr=8-1

I have obtained firm quotes from two test labs equipped for ISO 4548-12. It's looking like we've also secured sponsorship from vendors who have reason to very interested in the data. We'll still need some crowd funding to get 'er done, but we should be able to test four filters...Champion, Tempest, Wix/Napa, and the S15.

More later.

Very cool. I'll be happy to help out if all the data is going to become available to us.

+1 for helping fund the test.

the o-ring in the S15 gradually degraded and then suddenly failed causing this almost catastrophic leak

Drilled a few holes in the cooling fin closest to the connection. A worm gear clamp would probably be easier/better.How do you guys safety wire the S15 filter?

Or you don't?

Did they sell you 10 wrong size spares or did they somehow get bigger as the years went by?yep, this ain't good...

Along my S15 I ordered 10 spare o-rings... used the first o-ring for about 300 hours, and then, upon trying to install one of them spares, noticed that all had too big a diameter, though the height of the H seal was correct.

Luckily I was saved by rv8ch who provided some o-rings of the right size (thanks again Mickey).

Some engine stuff is critical. This o-ring, same as the Andair gascolator o-ring, is critical. Requires the right size, some lubrication, a proper torque, and safety wiring.

Do you mind sharing some additional data about the failure? Is this the original oring (200 hrs)? If not how many hours / cycles (removals) did this o-ring have on it? Before removing the filter, did you see the oring squeezed out from the body?I've been using the S15 filter in my 14 for the past 200h. A few days ago, just after take off noticed a strange smell in the cockpit, something like burning oil. Turned back immediately and landed safely. Flight time from departure to engine shut down was merely 4 minutes. During those 4 minutes I've lost over 3,5 qt of oil. Luckily, the remaining quart was enough to maintain nominal oil pressure. To make things worst the aircraft flew perfectly fine for 20 hours since the last oil change. Looks like, the o-ring in the S15 gradually degraded and then suddenly failed causing this almost catastrophic leak. There were no warning sings.

Googling around I've noticed that my incident is certainly not the first one:

Departure Emergency - Challenger Oil Filter

As you are aware, parts availability has been an issue lately. With that in mind, I decided to install a Challenger reusable oil filter on my 1995 Bravo. Actually, an A&P who works at my shop did it for me. I flew the airplane about an hour last weekend with no issues. This morning, as I depa...mooneyspace.com

I did the holes. Looks good; looks like it is something that belongs on the airplane! Easy peasy. Safety wired to where I ran the safety wire for the old style oil filter.Drilled a few holes in the cooling fin closest to the connection. A worm gear clamp would probably be easier/better.

Sorry, no pics. After the flight I was not in a mood. Frankly, the fact that I smelled the burning oil and decided to turn back was clearly an act of God. I mean all engine parameters were in the green and there was no logical explanation for my 180 turn. Correct me if I'm wrong, in NASA speak that kind of event is called a high visibility close callWould you have any pictures showing the deformed o ring? Measurements of old versus new o ring?

How tight was the filter?

It wasn't a matter of "years", but rather 7-8 months... what I've been wondering, is there a difference in size between the Challenger's and the S15's o-rings?Did they sell you 10 wrong size spares or did they somehow get bigger as the years went by?

I'd say it was too loose. I've always tightened my S15 to 18 Ft pounds as per the instructions. Seems way tight to me after wrenching for 50 years, but that's what the instructions say. Glad your instincts made you turn around.Sorry, no pics. After the flight I was not in a mood. Frankly, the fact that I smelled the burning oil and decided to turn back was clearly an act of God. I mean all engine parameters were in the green and there was no logical explanation for my 180 turn. Correct me if I'm wrong, in NASA speak that kind of event is called a high visibility close call

As the filter and ring is concerned: It was the 2nd oil change on that oring. The filter was hand tight + 1/4 turn, safety wired. From the outside the filter looked like nothing was wrong. Upon removal I've noticed a minor dent in the oring, say four thousands of an inch. Just a dent. That was enough.

Appreciate your opinion, if the filter would be too loose it would have been leaking oil for the past 20 hours. It didn'tI'd say it was too loose