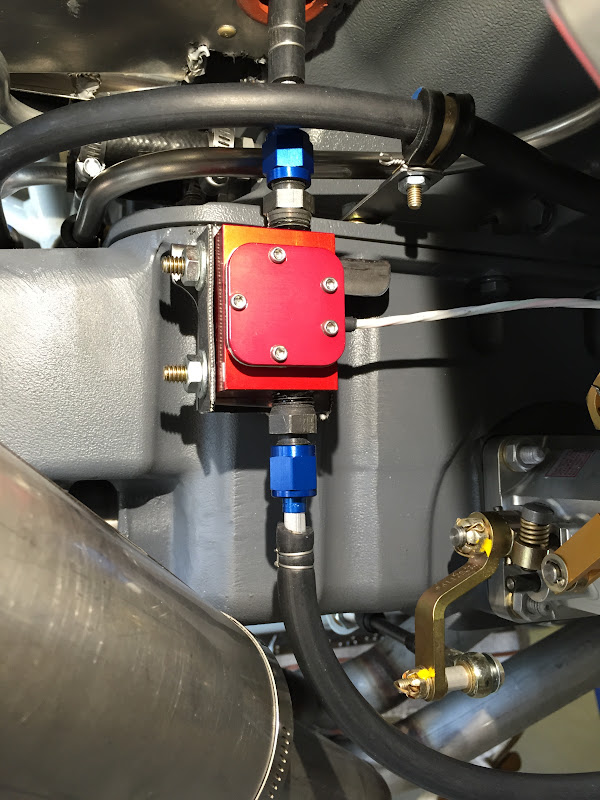

I'm sure "Red Cubes" have been located above the Throttle Body before.. I just have not seen pics posted here. All throttle linkages easily clear hoses. Cable supported by only by hoses. Hoses secured against excessive movement by clamps.. A soft rubber grommet was placed between cube and engine to "Tighten" up the overall installation. Permatex HP thread sealant used. None on first few threads - Steel fittings for fatigue resistance. All the installation rules seem to be met... (?)

(First time Poster to forum.)

Thanks Alan.

Cube1:

Cube1 by Arthur Karpinski, on Flickr

Cube1 by Arthur Karpinski, on Flickr

Cube2:

Cube2 by Arthur Karpinski, on Flickr

Cube2 by Arthur Karpinski, on Flickr

Hoses:

Hoses by Arthur Karpinski, on Flickr

Hoses by Arthur Karpinski, on Flickr

(First time Poster to forum.)

Thanks Alan.

Cube1:

Cube1 by Arthur Karpinski, on Flickr

Cube1 by Arthur Karpinski, on FlickrCube2:

Cube2 by Arthur Karpinski, on Flickr

Cube2 by Arthur Karpinski, on FlickrHoses:

Hoses by Arthur Karpinski, on Flickr

Hoses by Arthur Karpinski, on Flickr

Last edited: