Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Importance of Wire Support

- Thread starter KHeidorn

- Start date

Ken

Glad to see that you only had a burnt wire, it could have turned out much worse.

Quick question- did you have a circuit breaker or inline ANL fuse on the B lead,For this exact scenario? If so it it work? Or was the wire just arching across the crack in the terminal fitting?

Regards

Peter

Glad to see that you only had a burnt wire, it could have turned out much worse.

Quick question- did you have a circuit breaker or inline ANL fuse on the B lead,For this exact scenario? If so it it work? Or was the wire just arching across the crack in the terminal fitting?

Regards

Peter

Last edited:

Draker

Well Known Member

Did the wire fall out of the crimped terminal? I've already had one of my thick 6-ga wires fail in this way (did not pass the tug test during my pre-airworthiness condition inspection). Now I'm doubting all my crimps. Used one of those crimp tools you whack with a hammer. Wish there was a better way to secure large important wires to ring terminals.

Larry DeCamp

Well Known Member

Draker suggestionm

Any local automotive electric shop has dies and tools for a secure job. They do eveything from bulldozers to fire trucks where where reliability counts.

Any local automotive electric shop has dies and tools for a secure job. They do eveything from bulldozers to fire trucks where where reliability counts.

Last edited:

jneves

Well Known Member

Did the wire fall out of the crimped terminal? I've already had one of my thick 6-ga wires fail in this way (did not pass the tug test during my pre-airworthiness condition inspection). Now I'm doubting all my crimps. Used one of those crimp tools you whack with a hammer. Wish there was a better way to secure large important wires to ring terminals.

The hammer type are very prone to not getting a solid crimp. The best low cost options are one of these from Amazon.

https://www.amazon.com/IWISS-Termin...ocphy=1013950&hvtargid=pla-370713145091&psc=1

https://www.amazon.com/Hydraulic-Cr...la-894165565634&ref=&adgrpid=90730998421&th=1

FuturPilot

Well Known Member

Crimp ?

Any reason we can't crimp then solder the connectors?

Any reason we can't crimp then solder the connectors?

A question for the uninformed, please.

I'm not deep into wiring yet so I haven't geeked up to the required levels yet.

The only reference I've found regarding wire support/secure intervals is not to exceed 24 inches. Any of you better versed types find anything different? It would be appreciated and probably save me study time in the future.

I'm not deep into wiring yet so I haven't geeked up to the required levels yet.

The only reference I've found regarding wire support/secure intervals is not to exceed 24 inches. Any of you better versed types find anything different? It would be appreciated and probably save me study time in the future.

Draker

Well Known Member

Do those tools require special terminals? I've been using these types of terminals from DigiKey: https://www.digikey.com/en/products/detail/33467/A27076-ND/287757

The hammer type are very prone to not getting a solid crimp. The best low cost options are one of these from Amazon.

https://www.amazon.com/IWISS-Termin...ocphy=1013950&hvtargid=pla-370713145091&psc=1

https://www.amazon.com/Hydraulic-Cr...la-894165565634&ref=&adgrpid=90730998421&th=1

MacCool

Well Known Member

Any reason we can't crimp then solder the connectors?

I have been told by people smarter than me that solder imposes a level of brittleness to a connection that increases its likelihood of fracturing under vibration stress.

Did the wire fall out of the crimped terminal? I've already had one of my thick 6-ga wires fail in this way (did not pass the tug test during my pre-airworthiness condition inspection). Now I'm doubting all my crimps. Used one of those crimp tools you whack with a hammer. Wish there was a better way to secure large important wires to ring terminals.

https://www.steinair.com/product/non-insulated-terminal-crimper/

My retired USN CPO avionics tech seadaddy gave them a solid thumbs up.

Maybe I'm drinking the Kool-Aid but Steinair is my first choice for avionics stuff now unless they don't have it. Fantastic people and I would rather give my money to them than Amazon, and compare their wire prices to the usual suppliers.

Last edited:

Roadjunkie1

Well Known Member

Wire stresses

Wire/cable for aircraft/cars/other moving units, are made up of multiple strands to allow for flexing of that wire: the strands move on each other not allowing stress to build up on a specific area. This is why we do NOT use solid wire/cable on aircraft. Now: solder that wire and you have essentially turned it into a solid piece and the strands can no longer move on each other. The stress will be concentrated where the solder ends. Stranded wire can move slightly even in a terminal.

If you have solid wire ANYwhere in your airplane, go rip it out.....

I have been told by people smarter than me that solder imposes a level of brittleness to a connection that increases its likelihood of fracturing under vibration stress.

Wire/cable for aircraft/cars/other moving units, are made up of multiple strands to allow for flexing of that wire: the strands move on each other not allowing stress to build up on a specific area. This is why we do NOT use solid wire/cable on aircraft. Now: solder that wire and you have essentially turned it into a solid piece and the strands can no longer move on each other. The stress will be concentrated where the solder ends. Stranded wire can move slightly even in a terminal.

If you have solid wire ANYwhere in your airplane, go rip it out.....

Wire/cable for aircraft/cars/other moving units, are made up of multiple strands to allow for flexing of that wire: the strands move on each other not allowing stress to build up on a specific area. This is why we do NOT use solid wire/cable on aircraft. Now: solder that wire and you have essentially turned it into a solid piece and the strands can no longer move on each other. The stress will be concentrated where the solder ends. Stranded wire can move slightly even in a terminal.

If you have solid wire ANYwhere in your airplane, go rip it out.....

And while I agree with you that in most cases, crimping is better than soldering in aircraft, as they always say “there are NO absolutes!!”

Even the acknowledged expert in aircraft wiring, Bob Knuckolls, gives instructions for soldered joints, at least for big wires….

http://www.aeroelectric.com/articles/big_term.pdf

Paul

Walt

Well Known Member

The old fabric covered aircraft wire (I still have some from the old days which I still use for my 'B' lead) generally had a much higher strand count and was very flexible, similar to welding cable flexibility. Not sure where you can find a more flexible Tefzel as I think part of the stiffness from Tefzel is actually from the insulation itself.

https://www.awcwire.com/customersupport/techinfo/conductor-stranding

https://www.awcwire.com/customersupport/techinfo/conductor-stranding

Last edited:

This is a practice crimp I made using the tool I mention above. When i initially got the tool and did a couple practice ones I thought "Oh no, I've crushed the wire!" but a phone call to Steinair confirmed I was using the correct crimp, and all was fine, but I do make the crimps more in the center now.

Attachments

Ken

Glad to see that you only had a burnt wire, it could have turned out much worse.

Quick question- did you have a circuit breaker or inline ANL fuse on the B lead,For this exact scenario? If so it it work? Or was the wire just arching across the crack in the terminal fitting?

Regards

Peter

I do have an ANL fuse. The only damage was right at the terminal. This looks to me like just arcing across the crack. I could see one spot that looked like a glob of weld.

Did the wire fall out of the crimped terminal? I've already had one of my thick 6-ga wires fail in this way (did not pass the tug test during my pre-airworthiness condition inspection). Now I'm doubting all my crimps. Used one of those crimp tools you whack with a hammer. Wish there was a better way to secure large important wires to ring terminals.

The wire did not come out of the crimped terminal.

About half of the fellow builders I know had their large gauge Tefzel wires to either the alternator or the starter break within a few hundred hours, exactly as yours did. The other half don't have enough hours on their plane yet, but I'm waiting, confident they will eventually break.

I used welding cable, and those with broken Tefzel wires switched to it, and none of us have had any issues (coming up on 1000 hours on mine, several others approaching 2000 hours). Lots of threads on this in the forum.

And yes, a proper crimping tool is required, IMO. Beating a crimp with a hammer seems kind of neanderthalish, to me.

I used welding cable, and those with broken Tefzel wires switched to it, and none of us have had any issues (coming up on 1000 hours on mine, several others approaching 2000 hours). Lots of threads on this in the forum.

And yes, a proper crimping tool is required, IMO. Beating a crimp with a hammer seems kind of neanderthalish, to me.

Stevea

Well Known Member

Crimping, wire support, etc.

OK, so do not "beat a crimp (tool) with a hammer". Instead, put it in a vice and crank it down in a controlled manner, to the required crimp height. Worked for me on all the large crimps, with tefzel wire. None of them have misbehaved in 1000+ hrs.

Instead, put it in a vice and crank it down in a controlled manner, to the required crimp height. Worked for me on all the large crimps, with tefzel wire. None of them have misbehaved in 1000+ hrs.

The other important part of this, whatever wire is used, is to properly support the wire all the way out as close as possible to the termination point. This is not a place to scrimp on mounting hardware (ie: do not use zip ties to attach to some engine/engine mount hard point). Use Adel clamps to a rigid part of the engine, engine mount, etc. Yes, they can be a PITA to install (although there are several well documented methods to make installation easier). If the fat wires (or any wire, really) can not move, they can not fatigue, and can not break. And if ya don't want the wire to move, SECURE IT to a hard point.

Take a look under the hood of any modern car. Wire bundles are secured to something. Nothing is put in place, just hoping it will stay there.

Here are photos of my wire runs to the alternator and the starter:

And yes, a proper crimping tool is required, IMO. Beating a crimp with a hammer seems kind of neanderthalish, to me.

OK, so do not "beat a crimp (tool) with a hammer".

The other important part of this, whatever wire is used, is to properly support the wire all the way out as close as possible to the termination point. This is not a place to scrimp on mounting hardware (ie: do not use zip ties to attach to some engine/engine mount hard point). Use Adel clamps to a rigid part of the engine, engine mount, etc. Yes, they can be a PITA to install (although there are several well documented methods to make installation easier). If the fat wires (or any wire, really) can not move, they can not fatigue, and can not break. And if ya don't want the wire to move, SECURE IT to a hard point.

Take a look under the hood of any modern car. Wire bundles are secured to something. Nothing is put in place, just hoping it will stay there.

Here are photos of my wire runs to the alternator and the starter:

rapid_ascent

Well Known Member

Ryan,

I have a heavy duty crimper you can borrow. I think it makes pretty nice crimps for the larger wires.

I have a heavy duty crimper you can borrow. I think it makes pretty nice crimps for the larger wires.

OK, so do not "beat a crimp (tool) with a hammer".Instead, put it in a vice and crank it down in a controlled manner, to the required crimp height. Worked for me on all the large crimps, with tefzel wire. None of them have misbehaved in 1000+ hrs.

The other important part of this, whatever wire is used, is to properly support the wire all the way out as close as possible to the termination point. This is not a place to scrimp on mounting hardware (ie: do not use zip ties to attach to some engine/engine mount hard point). Use Adel clamps to a rigid part of the engine, engine mount, etc. Yes, they can be a PITA to install (although there are several well documented methods to make installation easier). If the fat wires (or any wire, really) can not move, they can not fatigue, and can not break. And if ya don't want the wire to move, SECURE IT to a hard point.

Take a look under the hood of any modern car. Wire bundles are secured to something. Nothing is put in place, just hoping it will stay there.

Here are photos of my wire runs to the alternator and the starter:

View attachment 27485

View attachment 27486

View attachment 27487

View attachment 27488

These are lovely wire runs and supports and all, BUT...the problem here is not, I think, with the wire run. It's with the *bend* in the wire to take it to the terminal post. The large, stiff wire wants to unbend into a straight run, thus putting stress on the crimped connecter, ultimately leading to a break (or some number of strands break, which then leads to heating in the remaining ones, etc.). At least, that's my guess, based on what I've seen on friends' RVs with the same wires and runs.

Stevea

Well Known Member

wire pre-bending and lug bending

OK. Probably should have mentioned this in my first post.

1: The fat wire running to the starter with the 90 degree bend in it was pre-bent prior to install. If the starter is removed the 90 degree bend stays put. The #2 tefzel does not want to spring back.

2: The smaller wire to the back of the alternator (unfortunately no photo showing the wire lug) comes in the the back of the alternator at approx a 30 degree angle, down from the fore/aft run to the alternator output post. The terminal lug has a corresponding bend so the lug fits on the output post without straining the crimp connection.

Bottom line is this: the wires need to come off the lug end aimed in the direction they need to run. Otherwise, I agree, the wire/lug crimp area will be forced into position and be under stress. I have found it acceptable to bend the lug (if required) up to 90 degrees to get the wire pointed where it needs to go. Just don't try to straighten the lug out again if the wire routing changes during build or in the future......re-terminate the wire end instead.

These are lovely wire runs and supports and all, BUT...the problem here is not, I think, with the wire run. It's with the *bend* in the wire to take it to the terminal post. The large, stiff wire wants to unbend into a straight run, thus putting stress on the crimped connecter, ultimately leading to a break (or some number of strands break, which then leads to heating in the remaining ones, etc.). At least, that's my guess, based on what I've seen on friends' RVs with the same wires and runs.

OK. Probably should have mentioned this in my first post.

1: The fat wire running to the starter with the 90 degree bend in it was pre-bent prior to install. If the starter is removed the 90 degree bend stays put. The #2 tefzel does not want to spring back.

2: The smaller wire to the back of the alternator (unfortunately no photo showing the wire lug) comes in the the back of the alternator at approx a 30 degree angle, down from the fore/aft run to the alternator output post. The terminal lug has a corresponding bend so the lug fits on the output post without straining the crimp connection.

Bottom line is this: the wires need to come off the lug end aimed in the direction they need to run. Otherwise, I agree, the wire/lug crimp area will be forced into position and be under stress. I have found it acceptable to bend the lug (if required) up to 90 degrees to get the wire pointed where it needs to go. Just don't try to straighten the lug out again if the wire routing changes during build or in the future......re-terminate the wire end instead.

dmattmul

Well Known Member

Cracked b lead

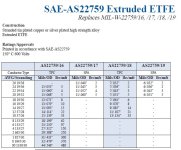

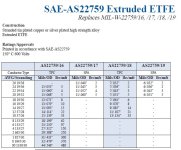

Last week with another 50 mins left to flight my primary bus amps draw went down to 0, voltage dropped from 14.2 to 13.4 volts and immediately received a CAS warning (Red on the amps and yellow on the volts) telling me I had a primary bus issue. (No kidding) I have simulated this before in-flight and everything worked as predicted. (Warning wise) I annually test my ampacity of my 2 batteries and knew that I had 13 amp-hours + left to have transponder and radio if required. I did load shed turning off the GTN and strobes and my amps dropped from 14 down to 6 amps. My essential bus was rock solid keeping the big fan turning appropriately. (Amps and volts right in-line) During the 50-minute flight I had time to ponder possible issues, alternator, belt, voltage regulator, just did a cowl removal and oil change the day before, came to mind. About 10 mins out turned on the radio, strobes and GTN, received clearance through a class D airspace and landed. After inspecting the wiring found like Ken my Amp connector had cracked and melted complete with copper puddles. It was inside the silicone boot and from the outside looked fine. The connector was not blackened like Ken's once pulled out of the boot. The wire was supported, and my guess is the day before I did the normal pull test on the lead. The crimp was fine and held. Prop balanced at ~ 250 hours and now have almost 400 hours on the airframe. My awg 8 wire was SAE-AS22759 with ETFE covering. What I have discovered is the awg/stranding can vary across different producers' cables. ACS sell their 8 awg with 133-29 awg conductors while Raychem sells their cable also 22759 with 665-36 awg conductors from Digi-Key. The b cable is protected with a 60-amp ANL fuse and shunt. I have purchased the RayChem cable and will replace existing cable with it. I have added not only the pull test but the pull boot back and inspect connector as part of my oil change procedure. I have a neighbor who is an A&P (And planes backed up everywhere) I showed the connector to, and he says he sees this quite often. By the way if some are wondering why my pad mounted alternator did not kick in it's because I am using the Bus Manager (very happy with it by the way) and it does not allow the essential bus to feed the primary bus (Diode protected) to ensure the integrity of the essential bus is maintained. Something I am thinking about modifying in the future after some more thought. (Cross-feed contactor only to be used if the primary bus charging system fails, we will see, Z-14)

The wire did not come out of the crimped terminal.

Last week with another 50 mins left to flight my primary bus amps draw went down to 0, voltage dropped from 14.2 to 13.4 volts and immediately received a CAS warning (Red on the amps and yellow on the volts) telling me I had a primary bus issue. (No kidding) I have simulated this before in-flight and everything worked as predicted. (Warning wise) I annually test my ampacity of my 2 batteries and knew that I had 13 amp-hours + left to have transponder and radio if required. I did load shed turning off the GTN and strobes and my amps dropped from 14 down to 6 amps. My essential bus was rock solid keeping the big fan turning appropriately. (Amps and volts right in-line) During the 50-minute flight I had time to ponder possible issues, alternator, belt, voltage regulator, just did a cowl removal and oil change the day before, came to mind. About 10 mins out turned on the radio, strobes and GTN, received clearance through a class D airspace and landed. After inspecting the wiring found like Ken my Amp connector had cracked and melted complete with copper puddles. It was inside the silicone boot and from the outside looked fine. The connector was not blackened like Ken's once pulled out of the boot. The wire was supported, and my guess is the day before I did the normal pull test on the lead. The crimp was fine and held. Prop balanced at ~ 250 hours and now have almost 400 hours on the airframe. My awg 8 wire was SAE-AS22759 with ETFE covering. What I have discovered is the awg/stranding can vary across different producers' cables. ACS sell their 8 awg with 133-29 awg conductors while Raychem sells their cable also 22759 with 665-36 awg conductors from Digi-Key. The b cable is protected with a 60-amp ANL fuse and shunt. I have purchased the RayChem cable and will replace existing cable with it. I have added not only the pull test but the pull boot back and inspect connector as part of my oil change procedure. I have a neighbor who is an A&P (And planes backed up everywhere) I showed the connector to, and he says he sees this quite often. By the way if some are wondering why my pad mounted alternator did not kick in it's because I am using the Bus Manager (very happy with it by the way) and it does not allow the essential bus to feed the primary bus (Diode protected) to ensure the integrity of the essential bus is maintained. Something I am thinking about modifying in the future after some more thought. (Cross-feed contactor only to be used if the primary bus charging system fails, we will see, Z-14)

Last edited:

The MIL-W-22759 or the later AS22759 wire specs specify the number of conductor strands and strand diameter, therefore cables manufactured by different companies to the same spec have the same number strands and strand diameter. As mentioned the number of strands is important to cable characteristics, including flexibility and cable finished diameter. I suspect that if the wire in ACS has a different strand count the catalog listing is either in error, or the wire isn’t the same spec.

On the large wire terminal issue, there are lots of satisfactory terminals, but each terminal must be used with the specified crimper to achieve the desired crimp conditions. I personally use the Tyco (Amp) solistrand terminals (designed specifically for AS22759 wire) with the Amp specified crimper. The crimper does #4- #00 terminals and has 26” handles with compound leverage. Still takes a lot of force to crimp. The pullt test for #2 wire is 440 lbs. Never had one fail. The crimp forces are high enough to deform the copper strands to fill in the spaces in between the strands and cold weld the strands to the terminal. This prevents corrosion between the strands. In my working days, had a project studying various crimps and their reliability.

On the large wire terminal issue, there are lots of satisfactory terminals, but each terminal must be used with the specified crimper to achieve the desired crimp conditions. I personally use the Tyco (Amp) solistrand terminals (designed specifically for AS22759 wire) with the Amp specified crimper. The crimper does #4- #00 terminals and has 26” handles with compound leverage. Still takes a lot of force to crimp. The pullt test for #2 wire is 440 lbs. Never had one fail. The crimp forces are high enough to deform the copper strands to fill in the spaces in between the strands and cold weld the strands to the terminal. This prevents corrosion between the strands. In my working days, had a project studying various crimps and their reliability.

wirejock

Well Known Member

Solder

Read this. The one place where he actually recommends soldering the terminal.

I used this16ton crimper.

If the wire doesn't fit snug before crimping, take a piece of 12 ga Romex wire. Grind a point then cut the piece off the depth of the terminal plus a little. Stick it in the center of the cable and tap it in till it's flush top the strands. Crimp. Move to the vise. Heat per the article till the solder melts and flows into the strands and pools a bit. Cool. Shrink wrap.

I've yanked as hard as possible on every one before installing and not a single one has let go. In fact, one wasn't clocked correctly so I tried to split it to take it off. Even after inserting a screwdriver and splitting the terminal, it still wouldn't let go. I had to cut it off.

I used this technique for the battery cables, ground cables, starter, alternator B lead and the two cables going inside to the Advanced Control Module.

Any reason we can't crimp then solder the connectors?

Read this. The one place where he actually recommends soldering the terminal.

I used this16ton crimper.

If the wire doesn't fit snug before crimping, take a piece of 12 ga Romex wire. Grind a point then cut the piece off the depth of the terminal plus a little. Stick it in the center of the cable and tap it in till it's flush top the strands. Crimp. Move to the vise. Heat per the article till the solder melts and flows into the strands and pools a bit. Cool. Shrink wrap.

I've yanked as hard as possible on every one before installing and not a single one has let go. In fact, one wasn't clocked correctly so I tried to split it to take it off. Even after inserting a screwdriver and splitting the terminal, it still wouldn't let go. I had to cut it off.

I used this technique for the battery cables, ground cables, starter, alternator B lead and the two cables going inside to the Advanced Control Module.

Last edited:

90 degree adapters

Does anyone make a 90 degree lug adapter suitable for large starter and alternator wires/cables?

So many alternators, and particularly starters, have their terminals oriented perpendicular to the crankshaft which mandates a 90 degree bend to hook-up.

George

Does anyone make a 90 degree lug adapter suitable for large starter and alternator wires/cables?

So many alternators, and particularly starters, have their terminals oriented perpendicular to the crankshaft which mandates a 90 degree bend to hook-up.

George

cvairwerks

Well Known Member

George: Here's one I found within a few seconds. I know that there are others out there, including copper ones.

https://www.digikey.com/en/products...MIsJjn8LSO_gIVShZMCh0WowcbEAYYBiABEgJ61PD_BwE

https://www.digikey.com/en/products...MIsJjn8LSO_gIVShZMCh0WowcbEAYYBiABEgJ61PD_BwE

Stevea

Well Known Member

making a 90 degree lug

Or, you can take the standard (straight) lug you have and bend it to whatever angle you need. 90 degrees will work fine if that fits your needs. Just make sure to make the bend in the same direction as the one shown on the web page. Also, make the bend around a curved part (1/8" steel rod or piece of hardwood with 1/16-1/8" radius on the edge for example). Don't make a sharp 90. I used my hand seamer which has a bit of a radius at the end of the jaws.

The lug on my alternator output lead has a 45 degree bend in it to get the wire headed in the right direction. I've done others at 90. No cracks, no issues.

Does anyone make a 90 degree lug adapter suitable for large starter and alternator wires/cables?

George: Here's one I found within a few seconds. I know that there are others out there, including copper ones.

https://www.digikey.com/en/products...MIsJjn8LSO_gIVShZMCh0WowcbEAYYBiABEgJ61PD_BwE

Or, you can take the standard (straight) lug you have and bend it to whatever angle you need. 90 degrees will work fine if that fits your needs. Just make sure to make the bend in the same direction as the one shown on the web page. Also, make the bend around a curved part (1/8" steel rod or piece of hardwood with 1/16-1/8" radius on the edge for example). Don't make a sharp 90. I used my hand seamer which has a bit of a radius at the end of the jaws.

The lug on my alternator output lead has a 45 degree bend in it to get the wire headed in the right direction. I've done others at 90. No cracks, no issues.

A 2 ga or a 20 ga cable/ wire has a weight. Both are suseptible to vibration.

This is especially true when a connection is made to a component on the engine. The weakest point is the crimped terminal.

It is important to support the cable/ wire colse to where it is connected.

Good luck

This is especially true when a connection is made to a component on the engine. The weakest point is the crimped terminal.

It is important to support the cable/ wire colse to where it is connected.

Good luck

dmattmul

Well Known Member

New b lead run

Re-ran the B lead to the ANL fuse with the flexible 8 awg and new connectors. Cable was supported in 4 places before and felt this should be adequate. The new hydraulic crimpers with the octagon head for 8 awg worked very well. Really like this cable. Very easy to work with. 36 awg stranded wire vs 29 awg makes a big difference. See spec sheets.

Re-ran the B lead to the ANL fuse with the flexible 8 awg and new connectors. Cable was supported in 4 places before and felt this should be adequate. The new hydraulic crimpers with the octagon head for 8 awg worked very well. Really like this cable. Very easy to work with. 36 awg stranded wire vs 29 awg makes a big difference. See spec sheets.