DakotaHawk

Well Known Member

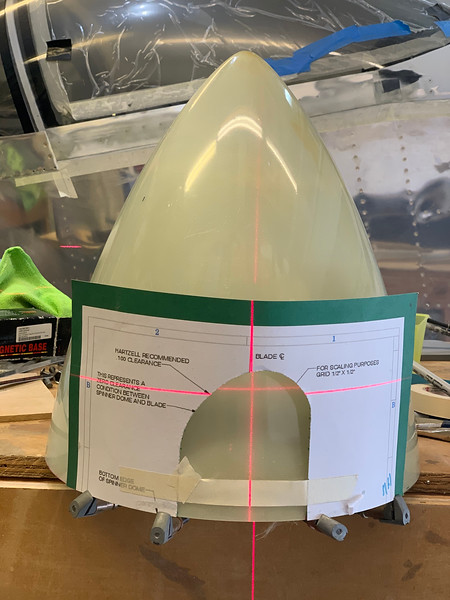

With a title like that, you would think that I had the perfect system and I'm here to provide a "how to" method to make sure that the spinner was perfectly centered and tracked with no wobble on the nose.

Alas, I'm just looking for hints on how to do it right.

Alas, I'm just looking for hints on how to do it right.