Brantel

Well Known Member

Not much info on here relating to the new Pepto Pink Cowl and its differences with the older ones so I will post pics of how one man is fitting his. I am using the tried and true hinges all around. Cheap and it works!

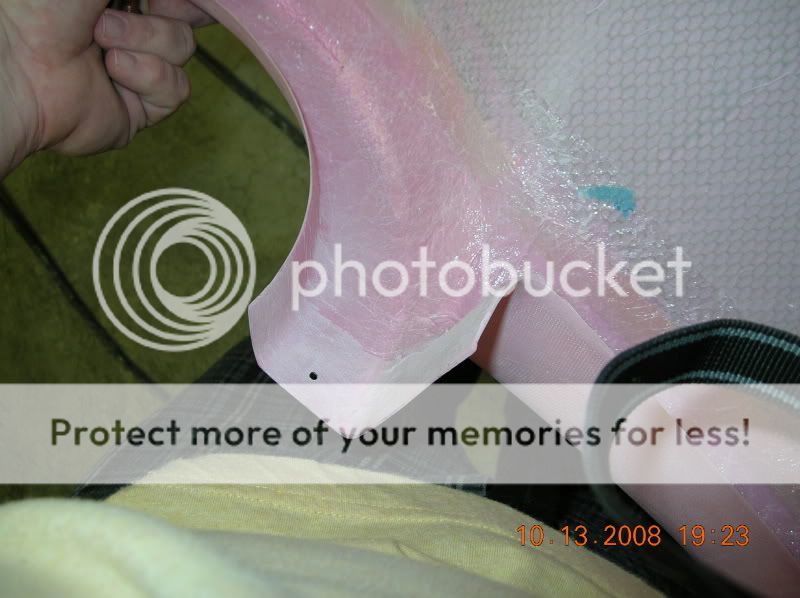

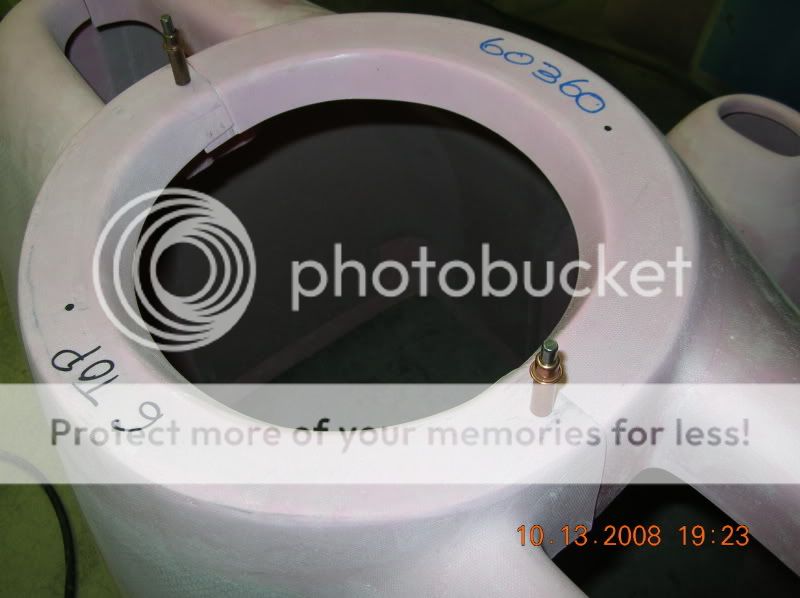

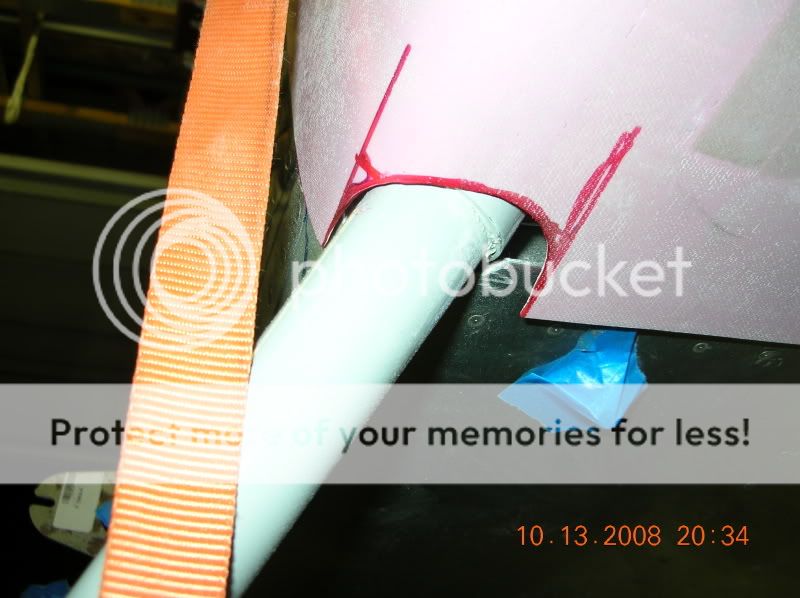

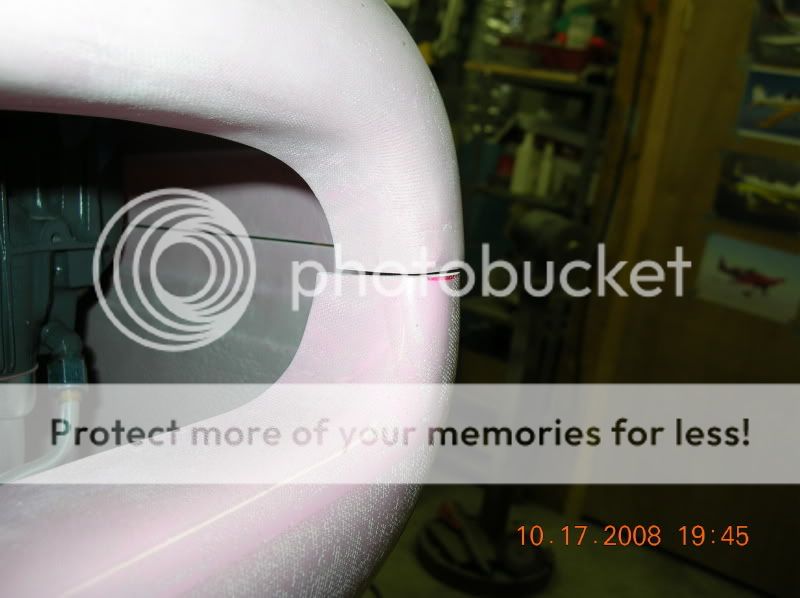

First I had to simulate the prop spacer I do not have yet so I picked up some 3" 1/2-20 fine threaded bolts from the hardware store. Along with the large spinner washers that come in the finish kit, I used these to attach the spinner backplate.

I cut some PVC pipe to make the 2-1/4" spacers. I am going to have a fixed pitch prop. It is my understanding that if your using a CS prop, you need a different length spacer.

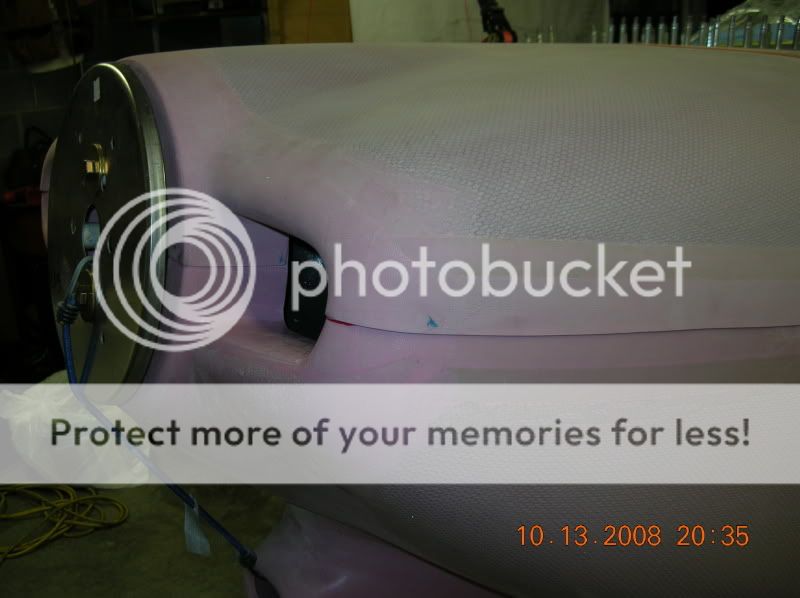

I then used a couple old paper back books as a spacer for getting the top of the cowl aligned with the spinner. I just kept taking pages from the book and fitting the top cowl till the spacing was correct.

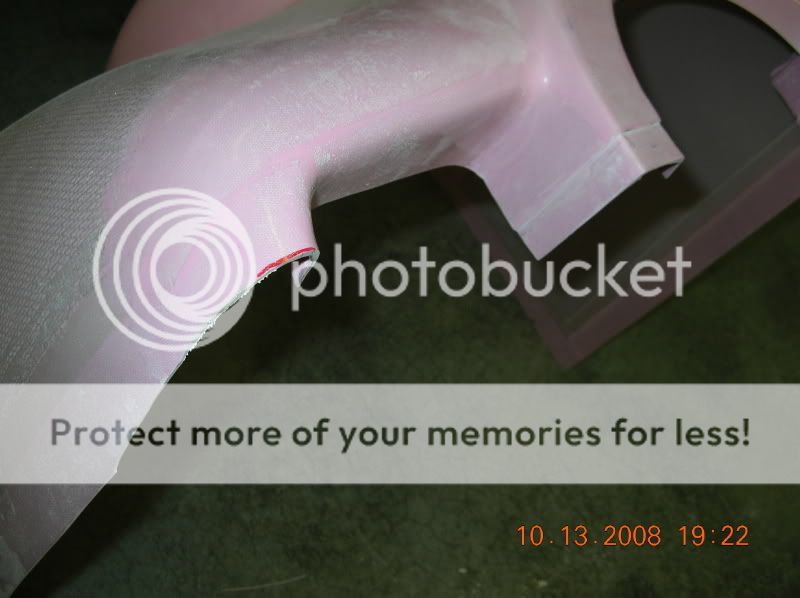

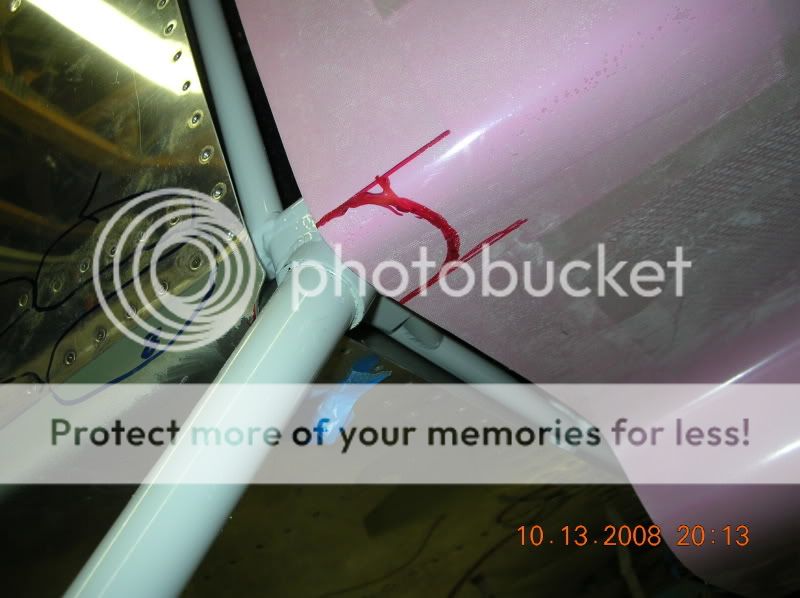

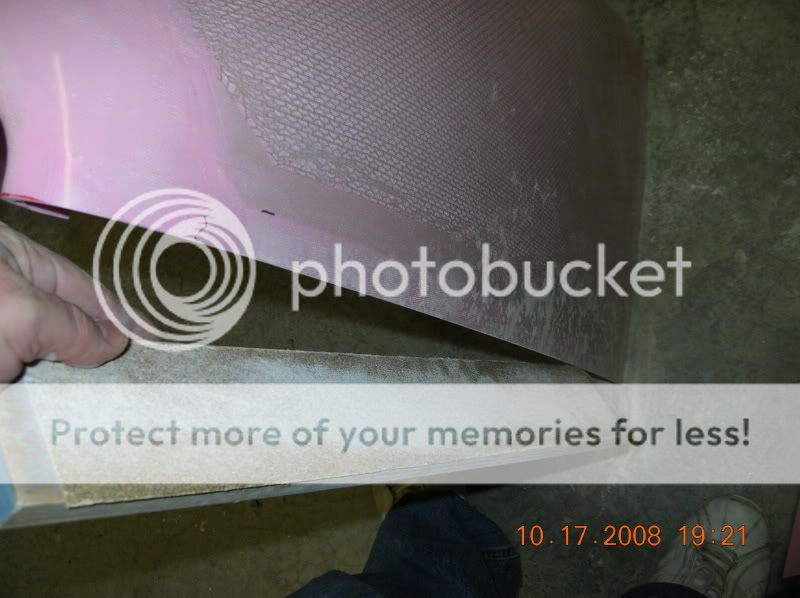

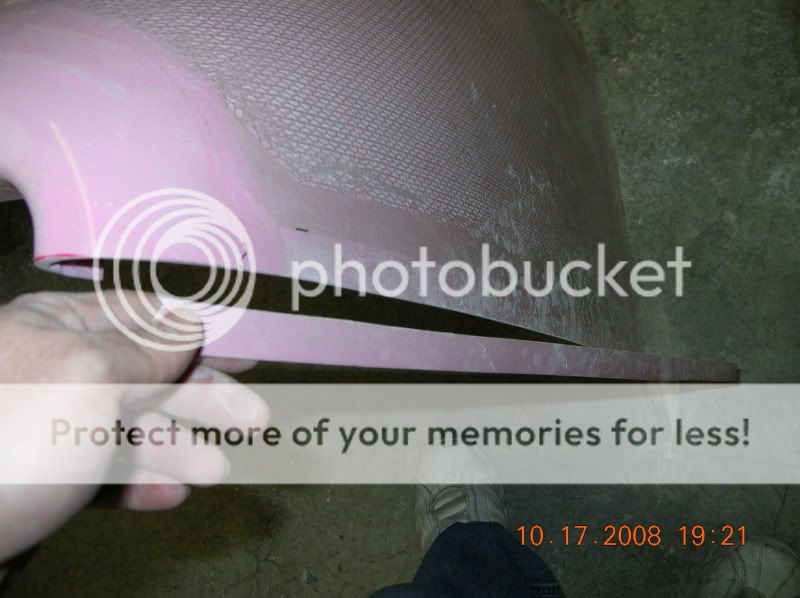

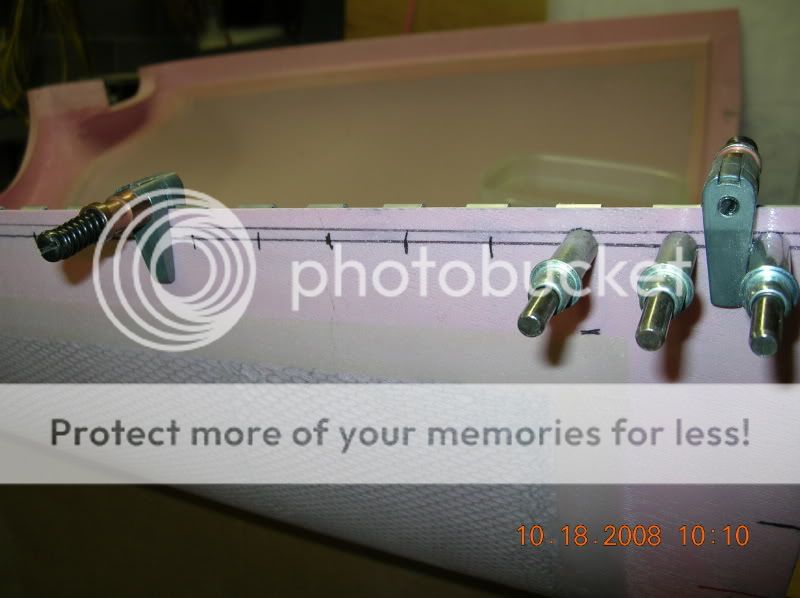

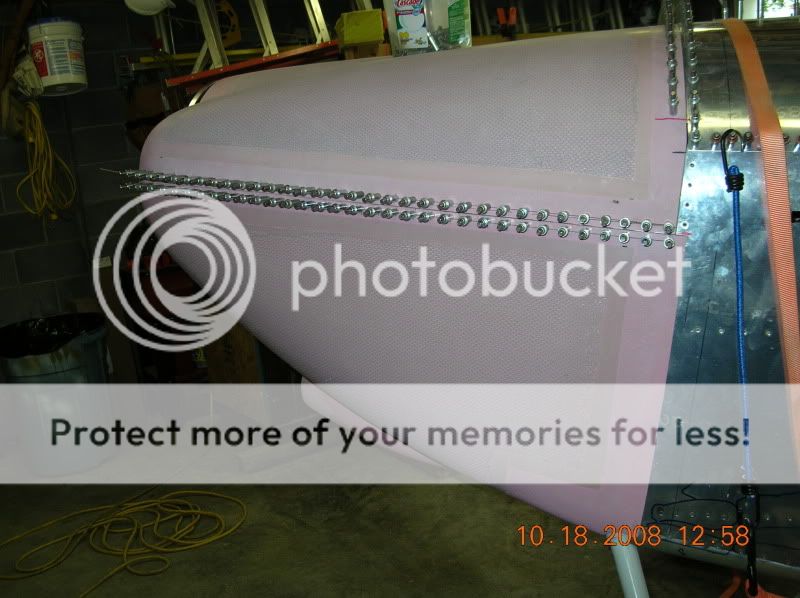

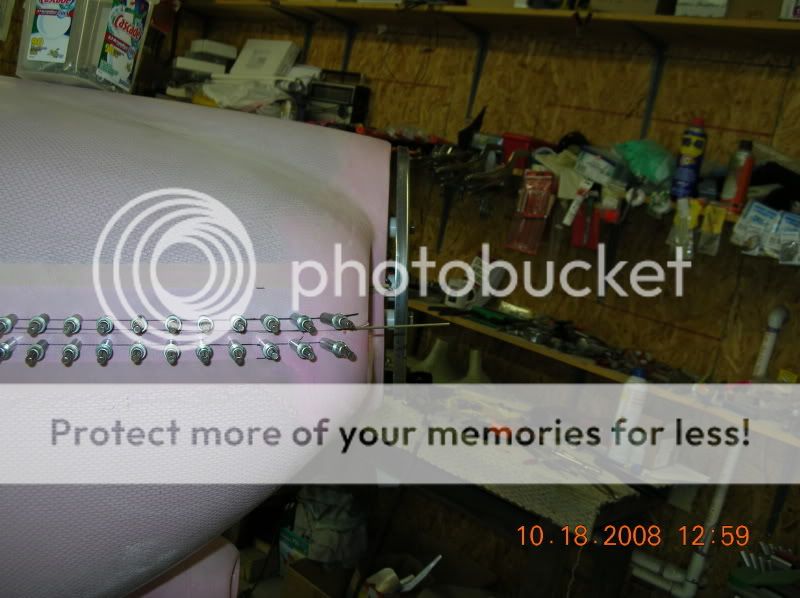

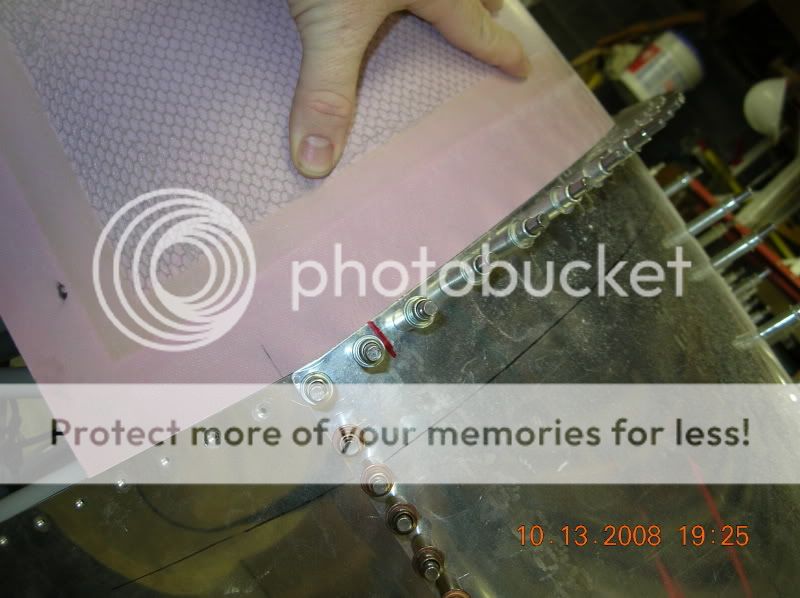

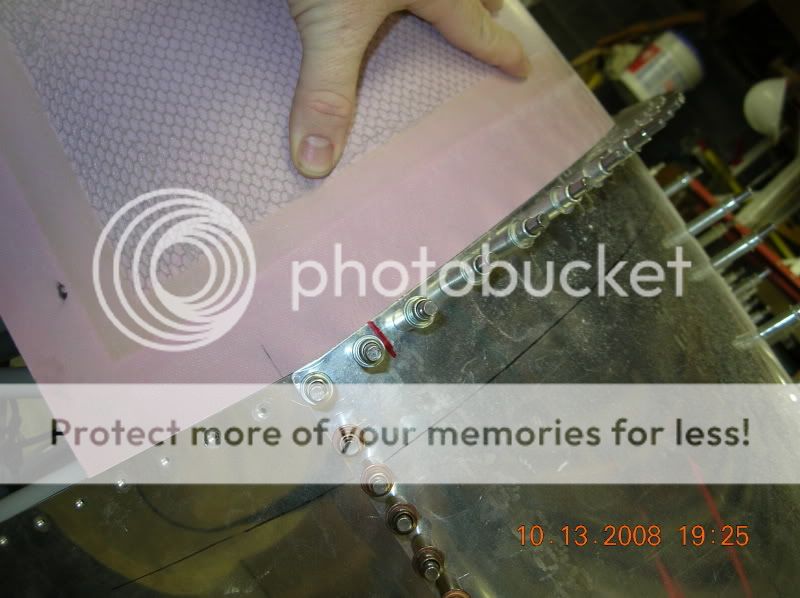

I then cut and drilled the hinges for the top. I spaced them right at the edge of the edge distance requirement for the holes in order to hide as much of the gap as possible between the cowl and the firewall area skins.

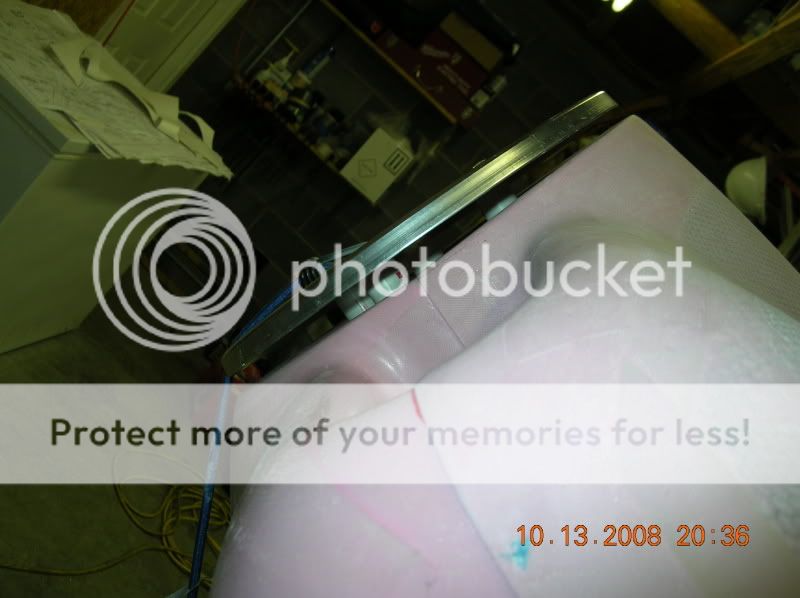

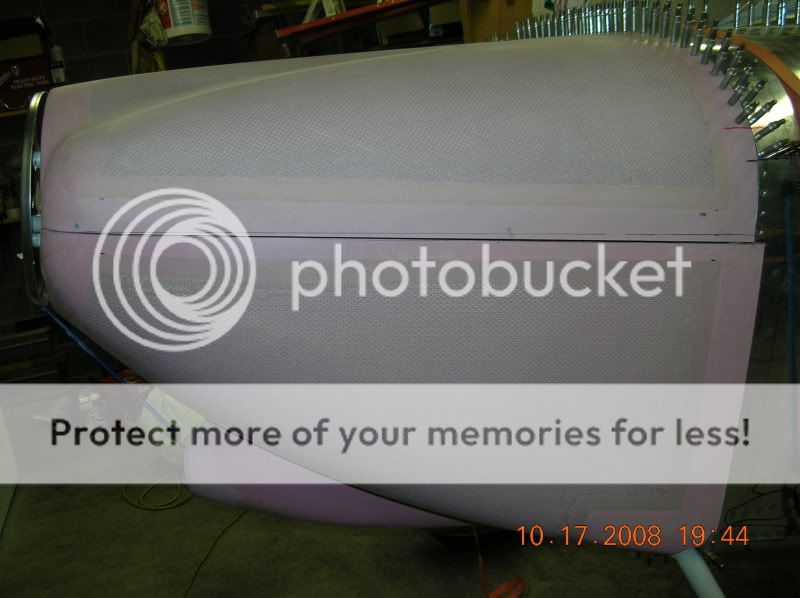

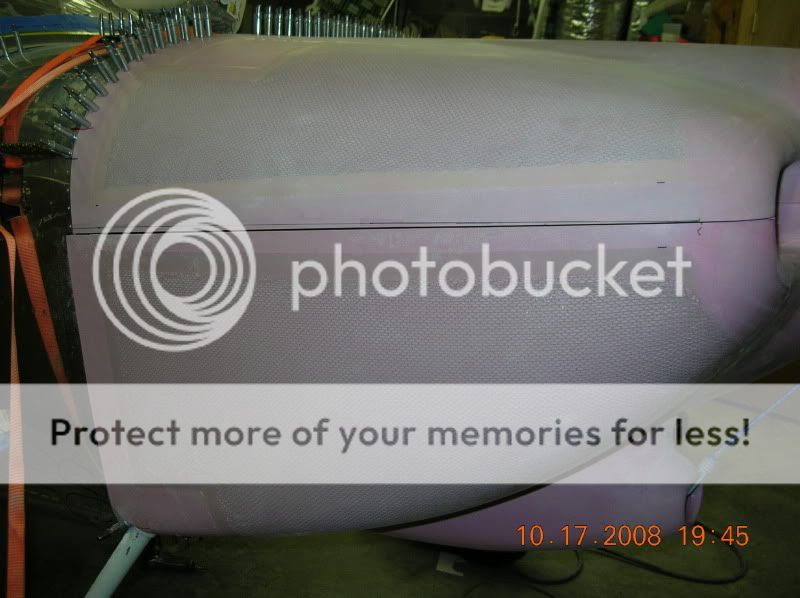

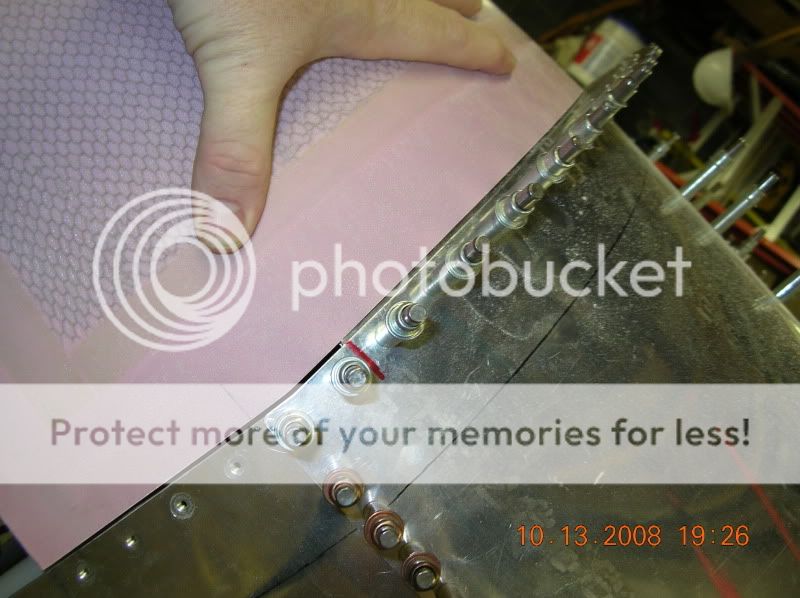

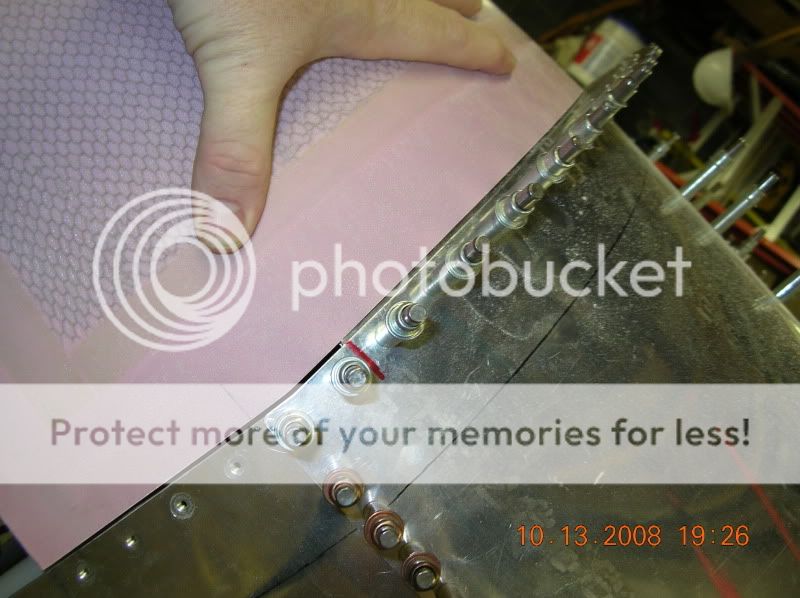

I drew a line 2" back from the front edge of the firewall skins, set my spinner to cowl gap at 1/8" and then marked the line onto the top aft side of the cowl. I then cut the top aft end to this mark.

Once this was fitting nice, I set the gap at 1/4" at the front and sanded in a 1/16" gap at the back for paint. I used a 16" long board with 60 grit glued to it for the sanding to ensure a nice straight edge.

First I had to simulate the prop spacer I do not have yet so I picked up some 3" 1/2-20 fine threaded bolts from the hardware store. Along with the large spinner washers that come in the finish kit, I used these to attach the spinner backplate.

I cut some PVC pipe to make the 2-1/4" spacers. I am going to have a fixed pitch prop. It is my understanding that if your using a CS prop, you need a different length spacer.

I then used a couple old paper back books as a spacer for getting the top of the cowl aligned with the spinner. I just kept taking pages from the book and fitting the top cowl till the spacing was correct.

I then cut and drilled the hinges for the top. I spaced them right at the edge of the edge distance requirement for the holes in order to hide as much of the gap as possible between the cowl and the firewall area skins.

I drew a line 2" back from the front edge of the firewall skins, set my spinner to cowl gap at 1/8" and then marked the line onto the top aft side of the cowl. I then cut the top aft end to this mark.

Once this was fitting nice, I set the gap at 1/4" at the front and sanded in a 1/16" gap at the back for paint. I used a 16" long board with 60 grit glued to it for the sanding to ensure a nice straight edge.

Last edited: