Now that the details have been addressed-- - what do we put for time in the log book?

Bill, good question. The short answer for me is that I add my pre and post "flying time" to my airframe time, which generally ends up with me adding .1 or .2 hours, although I've sat burning avgas for over a 1/2 hour waiting for IFR clearances... the longer version of my answer is muddled in the regulation definitions.

Here's a short refresher for everyone's edification on the nuances in regulation between Time In Service for an aircraft versus Flight Time for a pilot.

Title 14 CFR 1.1

"Flight Time means: Pilot time that commences when an aircraft moves under its own power for the purpose of flight and ends when the aircraft comes to rest after landing;"

This is the time YOU log for flying. A lot of folks use Hobbs time for this, but unless the aircraft moved under it's own power for the purpose of flying as soon as the hobbs started, and the hobbs was shut off as soon as the aircraft made it's final stop...it's not accurate pilot time, albeit likely close enough for government work - your call.

"Time in service, with respect to maintenance time records, means the time from the moment an aircraft leaves the surface of the earth until it touches it at the next point of landing."

This is the time logged for the aircraft

We then look to Part 91.147, which requires "The total time in service of the airframe, each engine, each propeller, and each rotor", as well as "The time since last overhaul of all items installed on the aircraft which are required to be overhauled on a specified time basis."

The Tach Time for the

engine provides its TSOH, as well as for the

propeller, and the flight timer keeps the TIS for the airframe (hence TTIS for the airframe). Adding the TSOH for each engine and propeller after each overhaul since new provides the Total Time In Service for those components.

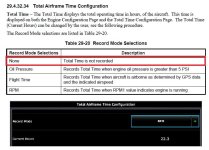

Fortunately, the G3X provides the function to track both flight time and tach time, so that is how I have my times configured in the system.

It's not surprising the myriad of interpretations of "logging time" considering the multiple references and cross-references required. And we haven't discussed instrument time, pilot in command, safety pilot or second in command time - and probably others I've not thought of at this moment. oof.