I have been running through old posts and looking at build sites and I haven't been able to find any pictures. For guys who used some sort of solid smooth wall tube for conduit, how are guys exiting wire bundles mid wing when the conduit continues to the tip? Did you end and begin the conduit? Did you put a hole in it? Pictures or explanations would be greatly appreciated.

Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Conduit exits

- Thread starter xblueh2o

- Start date

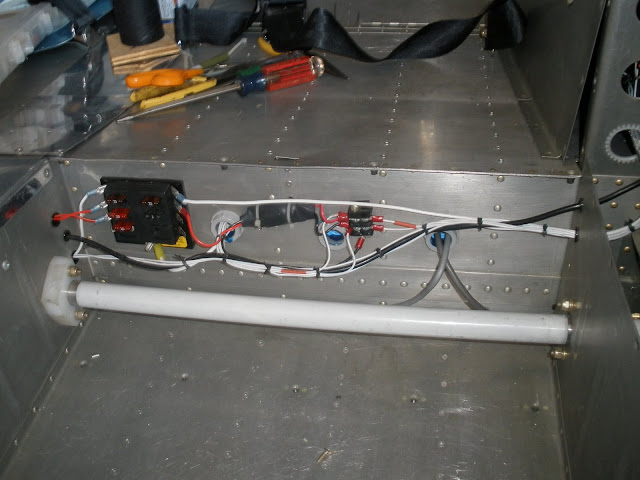

I used a 3/4” OD x 5/8” ID clear vinyl tubing from the root to the Pitot / Autopilot Servo area. It can be found in the very back of the Home Depot Aviation supply; Manufacturer is Watts, P/N SVLK10 $7 for 10 ft. It can be seen in picture coming from the left (inboard) side. The aluminum tubing is thin walled 3/4" OD tubing found at an actual Aviation supply store. I wanted to run the aluminum tubing all the way through, but you will find after you drill out the conduit holes to 3/4” in the ribs that most of the holes don’t line up very well once final size, especially in the inboard ribs for the wing walk area requiring flexible tubing. The Clear Vinyl tubing pulled through my completely assembled right wing without any problems from root to tip. I made a 1/2” x 1” cut easily in the tubing for the A/P servo wires. When I bought the wings, they had the black flexible convoluted tubing but it is a pain to run wire bundles though so I ripped it out and replaced it with the Vinyl tubing.

Last edited:

Thanks guys. Keep the ideas coming.

Dale,

I was in Home Dumpo the other day buying a ballast for a fluorescent fixture when I saw that stuff. I was intrigued by it due to the extreme light weight. I wondered if the size for T5 tubes might be better. I haven't totally decided against it but all I can find around here are the 4' sections and I am not all that interested in bonding two of them together. Did you run it through the lightning holes and secure it with cushion clamps or did you drill the ribs? If you drilled the ribs how did you protect the tube from vibration?

Mike,

what did you use for the actual conduit? Honest to goodness electrical conduit?

Randle,

I can't make out how you protected the tubbing. It looks like a grommet on the clear and a cushion clamp on the ally. Is that right?

Dale,

I was in Home Dumpo the other day buying a ballast for a fluorescent fixture when I saw that stuff. I was intrigued by it due to the extreme light weight. I wondered if the size for T5 tubes might be better. I haven't totally decided against it but all I can find around here are the 4' sections and I am not all that interested in bonding two of them together. Did you run it through the lightning holes and secure it with cushion clamps or did you drill the ribs? If you drilled the ribs how did you protect the tube from vibration?

Mike,

what did you use for the actual conduit? Honest to goodness electrical conduit?

Randle,

I can't make out how you protected the tubbing. It looks like a grommet on the clear and a cushion clamp on the ally. Is that right?

Mike S

Senior Curmudgeon

Mike,

what did you use for the actual conduit? Honest to goodness electrical conduit?

Yep. Blue flexible stuff they call "Smurf" tube.

DaleB

Well Known Member

Sam,

Here's some detail on how I did it: http://www.botkin.org/RV-build/?p=782. I made the brackets out of some stock I had handy and just pop riveted them in place. The tubing is secured with zip ties and RTV. Though the build log doesn't say it clearly, I put a good little glob of silicone between each bracket and the tube before cinching down the zip ties. If I'd seen T5 tube shields I'd have used those -- the T8 is a little bigger than needed! At least I'll be able to run coax through it if I need to.

My thinking is I'll run all the wires, put a few zip-ties or lacing cord in place to keep the wires secured, and see if/where I need to put adel clamps in there to keep wires from flopping around.

Here's some detail on how I did it: http://www.botkin.org/RV-build/?p=782. I made the brackets out of some stock I had handy and just pop riveted them in place. The tubing is secured with zip ties and RTV. Though the build log doesn't say it clearly, I put a good little glob of silicone between each bracket and the tube before cinching down the zip ties. If I'd seen T5 tube shields I'd have used those -- the T8 is a little bigger than needed! At least I'll be able to run coax through it if I need to.

My thinking is I'll run all the wires, put a few zip-ties or lacing cord in place to keep the wires secured, and see if/where I need to put adel clamps in there to keep wires from flopping around.